SA387Gr11Cl1 steel plate for petrochemical pipelines and production method thereof

A production method and steel plate technology, applied in the field of pipeline steel, can solve the problem that ordinary pipeline steel cannot meet the use requirements, and achieve the effects of excellent high temperature creep resistance, high compressive strength and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: The specific production process of the SA387Gr11Cl1 steel plate used in the petrochemical pipeline is as follows.

[0027] The thickness of this steel plate is 14.27mm, and it is composed of the following components by weight: C 0.10%, Si 0.57%, Mn 0.50%, P 0.006%, S 0.003%, Cr 1.14%, Mo 0.49%, Ni 0.13%, Cu 0.02% , Al 0.037%, Sb 0.001%, Sn 0.002%, As 0.003%, the balance is Fe and unavoidable impurities.

[0028] The process steps of this steel plate production method are as follows: (1) Smelting process: After the molten steel is smelted in an electric furnace, refined in an LF furnace and adjusted in composition, it is transferred to a vacuum degassing furnace (VD furnace) for vacuum treatment, and the vacuum degree is below 66Pa and kept at 20 The vacuum is broken in 1 minute, and the bag is lifted after 5 minutes of soft blowing.

[0029] (2) Casting process: casting the molten steel after smelting, and adopting continuous casting to obtain continuous ...

Embodiment 2

[0034] Example 2: The specific production process of the SA387Gr11Cl1 steel plate used in the petrochemical pipeline is as follows.

[0035] The thickness of this steel plate is 15.88mm, and it is composed of the following components by weight: C 0.09%, Si 0.52%, Mn 0.45%, P 0.006%, S 0.002%, Cr 1.12%, Mo 0.45%, Ni 0.11%, Cu 0.01% , Al 0.033%, Sb 0.001%, Sn 0.001%, As 0.004%, the balance is Fe and unavoidable impurities.

[0036]The process steps of this steel plate production method are as follows: (1) Smelting process: molten steel is smelted in an electric furnace, refined in an LF furnace, and its composition is adjusted, and then transferred to a VD furnace for vacuum treatment. Hang bag after 5 minutes.

[0037] (2) Casting process: Continuous casting of the smelted molten steel to obtain continuous casting slabs.

[0038] (3) Heating process: the maximum heating temperature of the soaking furnace is 1280°C, and the soaking temperature is 1250°C.

[0039] (4) Rolling ...

Embodiment 3

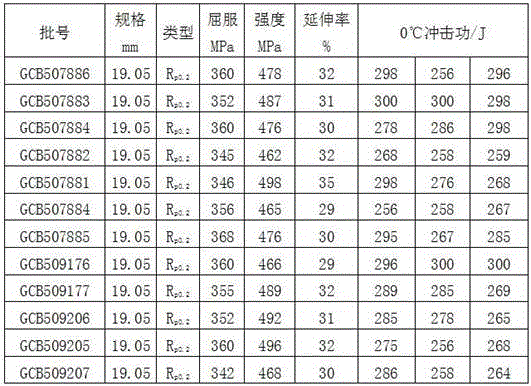

[0042] Embodiment 3: The specific production process of the SA387Gr11Cl1 steel plate used in the petrochemical pipeline is as follows.

[0043] The thickness of the steel plate is 19.05mm. The steel plate is composed of the following components by weight: C 0.09%, Si 0.62%, Mn 0.46%, P 0.005%, S 0.002%, Cr 1.15%, Mo 0.48%, Ni 0.10%, Cu 0.03%, Al 0.045%, Sb 0.001%, Sn 0.001%, As 0.003%, the balance is Fe and unavoidable impurities.

[0044] The process steps of this steel plate production method are as follows: (1) Smelting process: molten steel is smelted in an electric furnace, refined in an LF furnace, and its composition is adjusted, and then transferred to a VD furnace for vacuum treatment. Hang bag after 5 minutes.

[0045] (2) Casting process: die casting the smelted molten steel to obtain steel ingots.

[0046] (3) Heating process: the maximum heating temperature of the soaking furnace is 1280°C, and the soaking temperature is 1240°C.

[0047] (4) Rolling process: in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com