Function repair liquid for oxygen sensor and three-way catalyst and preparation method and use method

A three-way catalytic converter and oxygen sensor technology, applied in cleaning methods and appliances, chemical instruments and methods, cleaning methods using liquids, etc., can solve the problems of three-way catalytic converter damage, loss of catalytic effect, carrier pore clogging, etc. To achieve the effect of solving carbon deposition and heavy metal poisoning, enhancing solvency and less corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

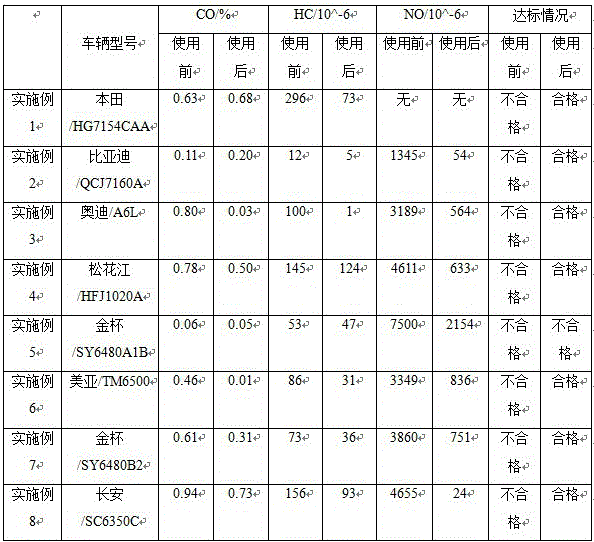

Examples

Embodiment 1

[0047] The method for using the functional repair fluid of the oxygen sensor and the three-way catalytic converter of this embodiment includes the following steps:

[0048] (1) Remove the oxygen sensor: remove the oxygen sensor installed on the intake pipe of the three-way catalytic converter, expose the oxygen sensor installation hole to the air, and install the signal shield on the oxygen sensor;

[0049] (2) Prepare the cleaning solution: Add 500ml of 100°C water to 1L of oxygen sensor and three-way catalytic converter function repair solution, stir for 1min, add 25L of water to obtain the diluted cleaning solution;

[0050] (3) Repair the three-way catalytic converter: start the car, and pass the cleaning solution diluted in step (2) into the intake pipe of the three-way catalytic converter through the oxygen sensor installation hole;

[0051] (4) Clean the three-way catalytic converter: pass water from the oxygen sensor installation hole into the intake pipe of the three-...

Embodiment 2

[0055] The method for using the functional repair fluid of the oxygen sensor and the three-way catalytic converter of this embodiment includes the following steps:

[0056] (1) Remove the oxygen sensor: remove the oxygen sensor installed on the intake pipe of the three-way catalytic converter, expose the oxygen sensor installation hole to the air, and install the signal shield on the oxygen sensor;

[0057] (2) Prepare the cleaning solution: Add 800ml of water at 80°C to 2L of oxygen sensor and three-way catalytic converter function repair solution, stir for 2 minutes, add 30L of water to obtain the diluted cleaning solution;

[0058] (3) Repair the three-way catalytic converter: start the car, and pass the cleaning solution diluted in step (2) into the intake pipe of the three-way catalytic converter through the oxygen sensor installation hole;

[0059] (4) Clean the three-way catalytic converter: pass water from the oxygen sensor installation hole into the intake pipe of the...

Embodiment 3

[0064] The method for using the functional repair fluid of the oxygen sensor and the three-way catalytic converter of this embodiment includes the following steps:

[0065] (1) Remove the oxygen sensor: remove the oxygen sensor installed on the intake pipe of the three-way catalytic converter, expose the oxygen sensor installation hole to the air, and install the signal shield on the oxygen sensor;

[0066] (2) Prepare cleaning solution: Add 200ml of 100°C water to 1.5L oxygen sensor and three-way catalytic converter function repair solution, stir for 1.5min, then add 20L of water to obtain the diluted cleaning solution;

[0067] (3) Repair the three-way catalytic converter: start the car, and pass the cleaning solution diluted in step (2) into the intake pipe of the three-way catalytic converter through the oxygen sensor installation hole;

[0068] (4) Clean the three-way catalytic converter: pass water from the oxygen sensor installation hole into the intake pipe of the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com