Core-layer foamed composite tubular product and preparation process thereof

A composite pipe and core layer technology, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy damage to the molecular structure of the foamed pipe material of the core layer and the reduction of service life, and achieve the simple and easy operation of the preparation method and the long service life. Long, low energy dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

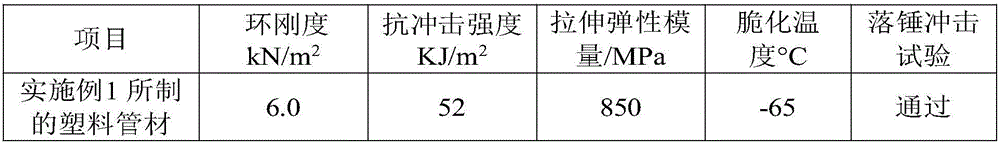

Embodiment 1

[0032] A core-layer foam composite pipe is composed of three coaxial layers of inner layer material, core layer foam layer and outer layer material;

[0033] The raw materials for preparing the inner layer material and their weight parts include: 50 parts of medium density polyethylene, 5 parts of low density polyethylene, 0.05 part of silicon dioxide passing through a 1500 mesh sieve, 0.05 part of calcium carbonate passing through a 2500 mesh sieve, polyoxyethylene 0.05 parts of ethylene;

[0034] The raw materials and parts by weight for preparing the core foam layer include: 60 parts of ethylene-maleic anhydride graft copolymer, 3 parts of styrene-butadiene rubber, 0.03 part of calcium carbonate, and 0.01 part of molybdenum oxide;

[0035] The raw materials and parts by weight for preparing the outer layer material include: 80 parts of polyvinyl chloride, and 0.5 part of MBS resin.

[0036] The thickness ratio of inner layer material, core foam layer and outer layer materi...

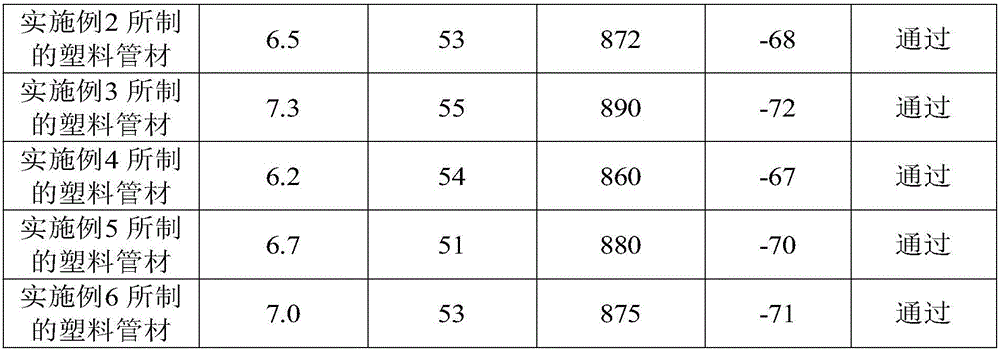

Embodiment 2

[0038] A core-layer foam composite pipe is composed of three coaxial layers of inner layer material, core layer foam layer and outer layer material;

[0039] The raw materials for preparing the inner layer material and parts by weight thereof include: 70 parts of medium density polyethylene, 15 parts of low density polyethylene, 0.15 part of silicon dioxide passing through a 2000 mesh sieve, 0.15 part of calcium carbonate passing through a 3000 mesh sieve, polyoxyethylene 0.15 parts of ethylene;

[0040] The raw materials and parts by weight for preparing the core foam layer include: 80 parts of ethylene-maleic anhydride graft copolymer, 12 parts of styrene-butadiene rubber, 0.09 parts of magnesium carbonate, and 0.01-0.05 parts of samarium oxide;

[0041] The raw materials and parts by weight for preparing the outer layer material include: 100 parts of polyvinyl chloride, and 1.5 parts of MBS resin.

[0042] The thickness ratio of inner layer material, core foam layer and ou...

Embodiment 3

[0044] A core-layer foam composite pipe is composed of three coaxial layers of inner layer material, core layer foam layer and outer layer material;

[0045] The raw materials for preparing the inner layer material and their parts by weight include: 60 parts of medium density polyethylene, 10 parts of low density polyethylene, 0.1 part of silicon dioxide passing through a 1800 mesh sieve, 0.1 part of calcium carbonate passing through a 2700 mesh sieve, polyoxyethylene 0.1 part of ethylene;

[0046] The raw materials and parts by weight for preparing the core foam layer include: 70 parts of ethylene-maleic anhydride graft copolymer, 8 parts of styrene-butadiene rubber, 0.06 part of carbon black, and 0.03 part of cerium oxide;

[0047] The raw materials and parts by weight for preparing the outer layer material include: 90 parts of polyvinyl chloride, and 1.0 part of MBS resin.

[0048] The thickness ratio of inner layer material, core foam layer and outer layer material is: 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com