Production method and manufacturing technology for corn stalk moulded board

A technology of corn stalks and production methods, which is applied in the field of molded board production, can solve the problems of large density deviation, high wet expansion rate, and large energy consumption, and achieve the effects of reducing density deviation, solving high expansion rate, and reducing procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

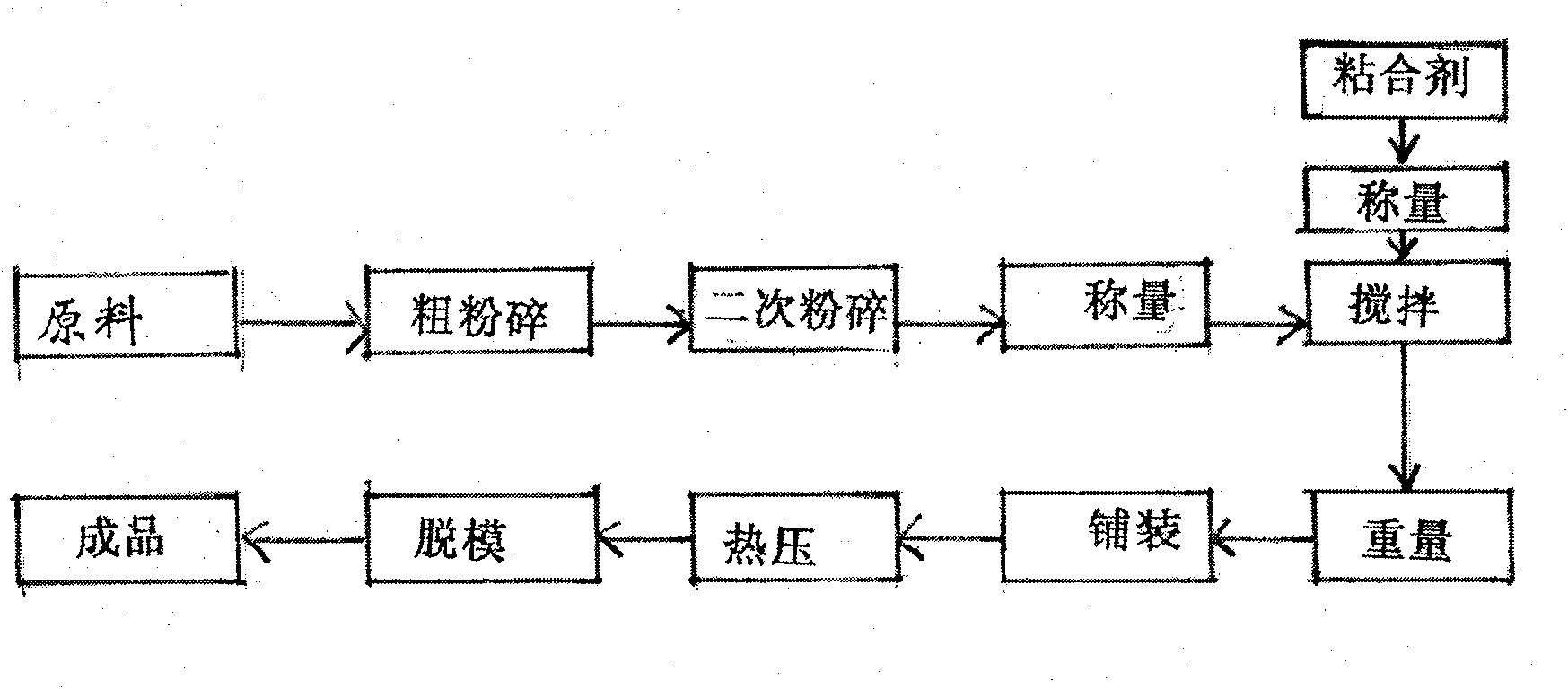

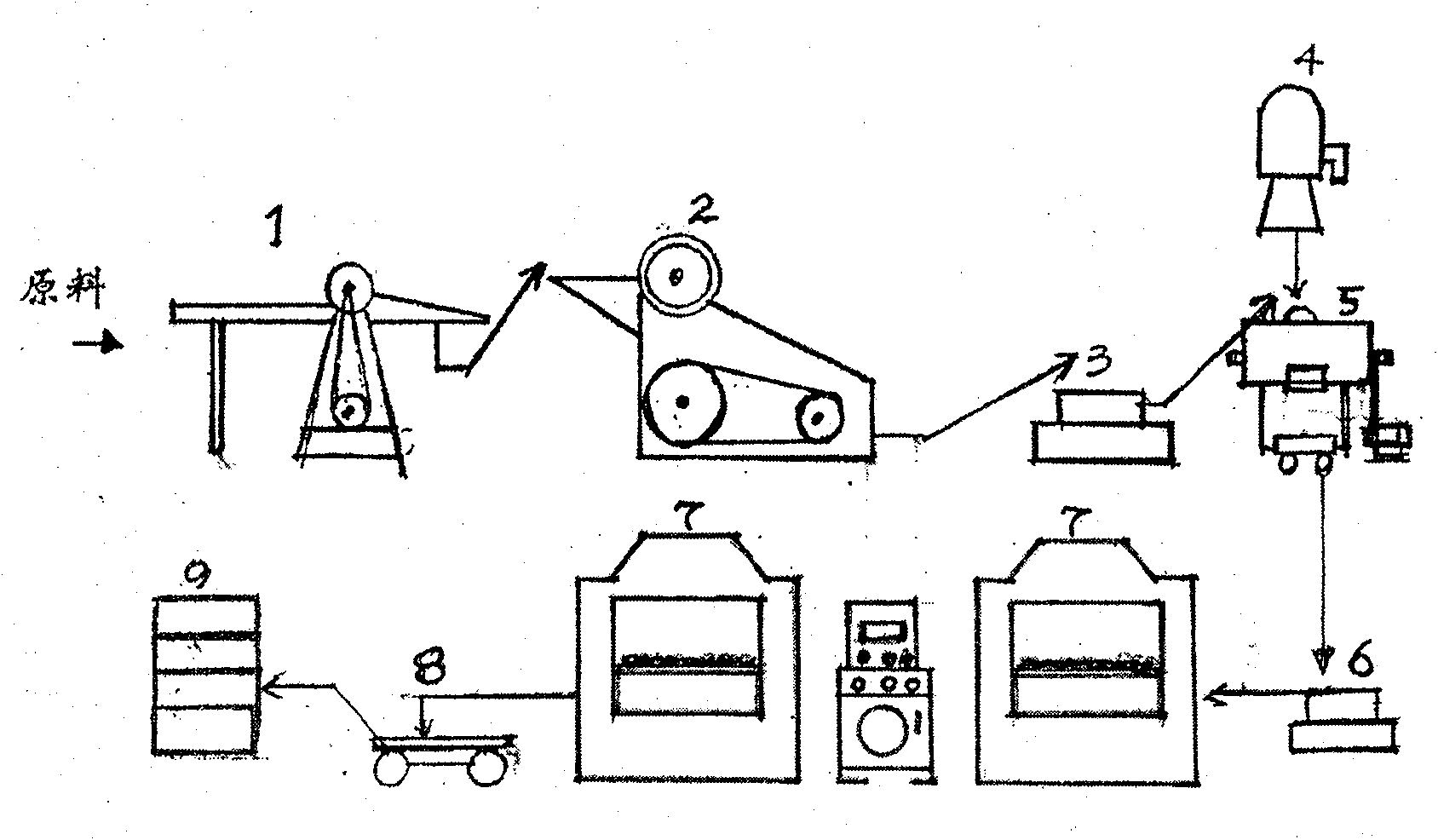

Method used

Image

Examples

Embodiment

[0011] Embodiment: making 1300*1300*10mm board

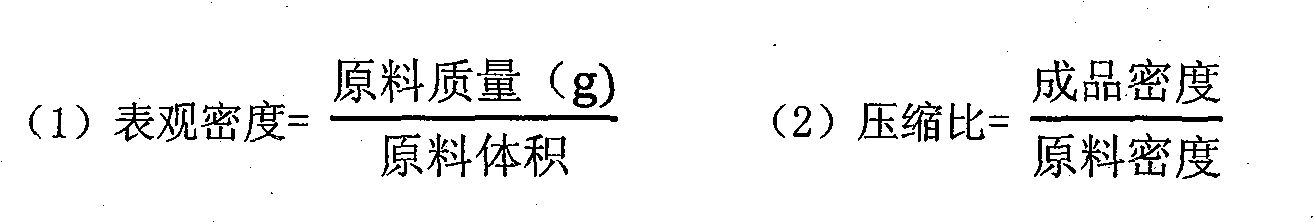

[0012] 1. Parameters of the material preparation section: (1) The moisture content of the raw material is below 20%, the particle size of the rough material is 10-25mm, the particle size of the secondary crushed material is 8-10mm, the content is 20%, the medium material is 5-8mm, the content is 40%, the fine Material 1-5mm, content 40%, apparent density 0.125g / cm 3 . (2) Reference wood apparent density 0.40-0.80g / cm 3 , to obtain the density of the formed board to take 0.50g / cm 3 . (3) Determine the compression ratio: density of finished board ÷ apparent density of raw material = 0.5÷0.125 = 4, determine the thickness of the slab for mold laying, the amount of each board is 8.5kg, and the amount of glue mixed is 20-30%.

[0013] 2. Determine the process parameters during pressing, (1) The pyrolysis temperature of corn stalks is 110-200°C, the curing temperature of the modified urea-formaldehyde resin adhesive is 105-125°C, ...

Embodiment 2

[0014] Embodiment 2, making 130*130*25mm board

[0015] 1. Determine the material preparation parameters: (1) The moisture content of raw materials is 20%, the particle size of coarse grinding is 10-25mm, the particle size of secondary grinding coarse material is 10-15mm20%, the particle size of medium material is 5-10mm30%, and the particle size of fine material is 1- 5mm%, the calculated apparent density of raw materials is 0.115g / cm 3 . (2) Select the density of the forming board to be 0.4g / cm 3 . (3) Calculation of compression ratio=formed plate density÷raw material apparent density=0.40÷0.115=3.4 is taken as 3, and the thickness of the plate is determined. The material used for each plate is 14.5kg, and the amount of adhesive is 30%.

[0016] 2. Determining process parameters: (1) Same as Example 1, pyrolysis temperature 110-200°C, curing temperature of modified urea-formaldehyde resin adhesive 105°C-125°C, pressure 1.2-2.0MPa, time 5-12min. (2) Determine the thermal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com