Antibacterial plastic bag used for packaging vegetable and production process thereof

A technology for plastic bags and vegetables, applied in the field of plastic product manufacturing, can solve the problems of living environment impact, rot, peculiar smell, etc., and achieve the effects of high film-forming properties, improved antibacterial properties, and high adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

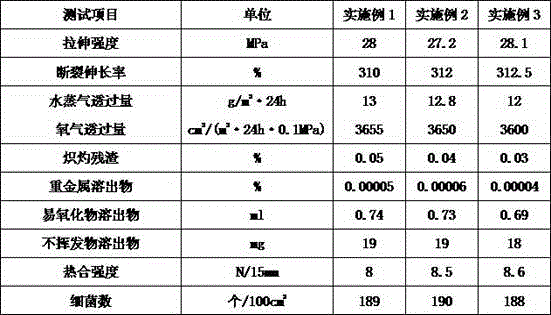

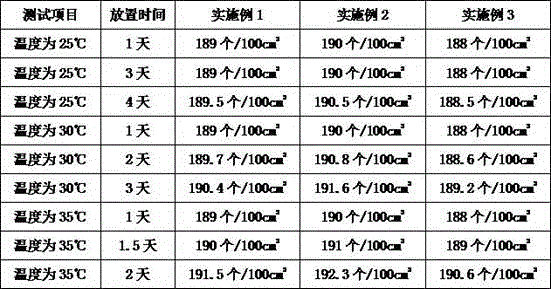

Examples

Embodiment 1

[0020] An antibacterial plastic bag used for vegetable packaging is composed of the following components in parts by weight: 100 parts of polyethylene, 50 parts of acrylonitrile, 27 parts of butadiene, 23 parts of licorice, 25 parts of black plum, 45 parts of Pu'er tea, 24 parts of bitter gourd, 6 parts of preservative, 3 parts of coupling agent, 3 parts of toughening agent, 6 parts of starch, and 2 parts of potassium citrate.

[0021] The preservative is a mixture of grape skins, garlic, ginger and lotus leaves.

[0022] The composition ratio of the grape skin, garlic, ginger and lotus leaf is 1:5:3:3.

[0023] The production process of the preservative is as follows: 1) Put the lotus leaves into a cutting machine to cut them, put the cut lotus leaves into the fermentation tank, make the lotus leaves seal and ferment at 20°C for 12 hours, and put the fermented lotus leaves Put the lotus leaf into the cutting machine and cut it repeatedly, rinse the lotus leaf with phosphoric...

Embodiment 2

[0032] An antibacterial plastic bag used for vegetable packaging is composed of the following components by weight: 100 parts of polyethylene, 60 parts of acrylonitrile, 18 parts of butadiene, 32 parts of licorice, 20 parts of ebony, 60 parts of Pu'er tea, 18 parts of bitter gourd, 8 parts of preservative, 1 part of coupling agent, 5 parts of toughening agent, 4 parts of starch, and 3 parts of potassium citrate.

[0033] The preservative is a mixture of grape skins, garlic, ginger and lotus leaves.

[0034] The composition ratio of the grape skin, garlic, ginger and lotus leaf is 1:5:3:3.

[0035] The production process of the preservative is as follows: 1) Put the lotus leaves into a cutting machine to cut them, put the cut lotus leaves into the fermentation tank, make the lotus leaves seal and ferment at 20°C for 12 hours, and put the fermented lotus leaves Put the lotus leaves into the cutting machine and cut them repeatedly. After washing the cut lotus leaves with phospho...

Embodiment 3

[0044] An antibacterial plastic bag used for vegetable packaging, which consists of the following components by weight: 100 parts of polyethylene, 50 parts of acrylonitrile, 20 parts of butadiene, 30 parts of licorice, 21 parts of dark plum, 50 parts of Pu'er tea, 23 parts of bitter gourd, 7 parts of preservative, 2 parts of coupling agent, 4 parts of toughening agent, 4 parts of starch, 3 parts of potassium citrate.

[0045] The preservative is a mixture of grape skins, garlic, ginger and lotus leaves.

[0046] The composition ratio of the grape skin, garlic, ginger and lotus leaf is 1:5:3:3.

[0047] The production process of the preservative is as follows: 1) Put the lotus leaves into a cutting machine for cutting, put the cut lotus leaves into the fermentation tank, make the lotus leaves seal and ferment at 19°C for 14 hours, and put the fermented lotus leaves Put the lotus leaf into the cutting machine and cut repeatedly, rinse the lotus leaf with phosphoric acid water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com