Rubber sealing product and preparation method and application thereof

A technology of rubber seals and products, applied in mechanical equipment, cocks including cut-off devices, valve devices, etc., can solve the problems of inability to vulcanize high-elasticity rubber seals, inability to vulcanize and mold rubber seals, etc., and achieve excellent gas resistance and rapid Pressure release performance, excellent shear and extrusion resistance, long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

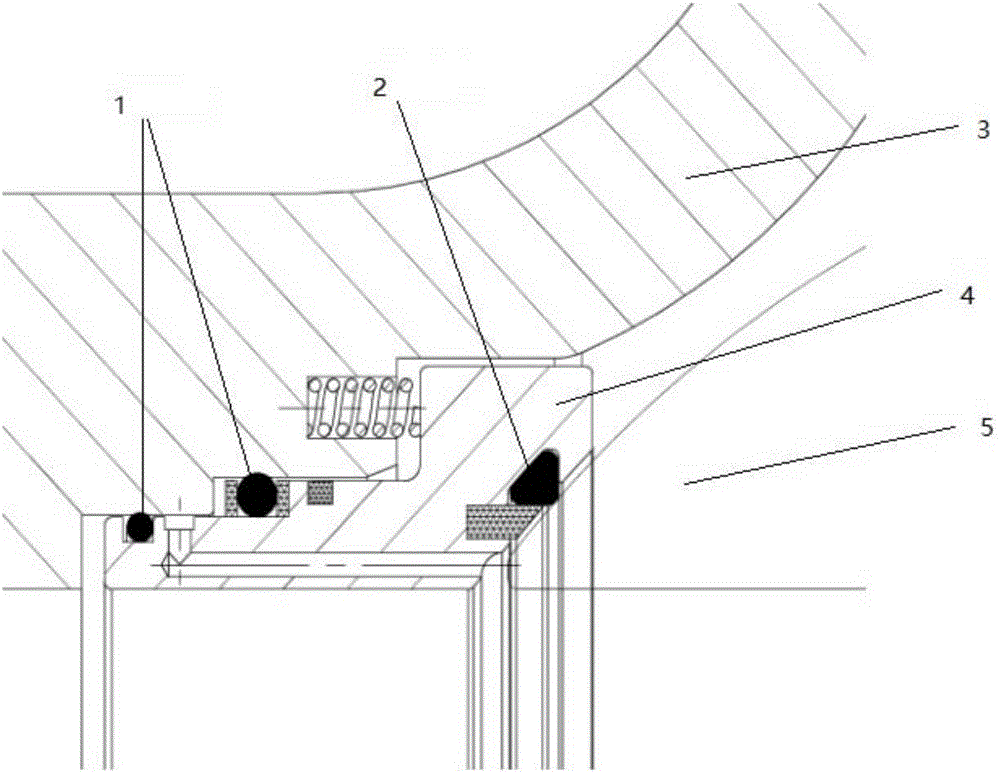

Image

Examples

Embodiment 1-6

[0058] Take and prepare materials by the formula (weight part) consumption of the embodiment 1-6 shown in table 1, earlier under the temperature of about 80 ℃, 1 / 2 rubber polymer is in two-roll mill (Taiwan Wei Fuxing 12 inch ) to be masticated evenly and covered with rolls, then PPTA pulp (or pulp masterbatch) is added to the open mill to make it evenly mixed, and then the remaining 1 / 2 of the rubber polymer is added to the open mill to mix evenly. Then mix the vulcanizing agent, carbon black filler and other rubber additives evenly, and slowly add them into the open mill to make them mix evenly with the rubber, and then release the sheet to obtain the rubber compound. After the prepared mixed rubber was aged for about 16 hours, it was re-milled and produced into tablets for later use. Under the condition of one-stage vulcanization for 10 minutes at a temperature of about 180° C., the obtained rubber mixture was molded and vulcanized into a standard rubber test piece, and the...

Embodiment 7-9

[0066] The formula (parts by weight) of the embodiment 7-9 shown in table 3 is used to take the raw materials, and the tetrapropylene fluororubber 100H, carbon black, aramid pulp, cross-linking agent TAIC-S70 and P-14 (40%) and mold release agent are added in the open mill (same as Example 1), and mixed evenly at about 80°C, Obtain tetrapropylene fluoride rubber compound rubber. Prepare the material. The mixed rubber of this example is molded and vulcanized into a standard rubber test piece at a temperature of 180° C. for 10 minutes in one-stage vulcanization, and then vulcanized in a second stage for 4 hours at a temperature of 200° C.

[0067] table 3

[0068]

[0069] The test pieces prepared in Examples 7-9 were prepared and tested according to the above-mentioned standard test strips, and the specific performance data are as described in Table 4.

[0070] Table 4

[0071]

[0072] As can be seen from the data in Table 4, in tetrapropylene fluorine rubber, the ha...

Embodiment 10-15

[0074] Weigh the raw materials according to the formula (parts by weight) of Examples 10-15 shown in Table 5, then add raw materials such as fluororubber peroxide, carbon black, aramid pulp, vulcanizing agent and processing aids to the mill (Same as Example 1), kneaded at 80° C. to obtain a fluororubber compound. The mixed rubber of this embodiment was molded and vulcanized into a standard rubber test piece at a temperature of 180° C. under the condition of one-stage vulcanization for 10 minutes, and then vulcanized in two stages at a temperature of 200° C. for 12 hours.

[0075] table 5

[0076]

[0077] The test pieces prepared in Examples 10-15 were prepared and tested according to standard test strips, and the performance data of the examples are as described in Table 6.

[0078] Table 6

[0079]

[0080] From the data in Table 6, it can be seen that the In the fluororubber of the peroxidation vulcanization system, adding a certain amount of aramid pulp to Exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com