A kind of superhydrophobic polypropylene film and preparation method thereof

A polypropylene film and super-hydrophobic technology, applied in coatings and other directions, can solve the problems of expensive fluorine-containing compounds and limited popularization and application, and achieve the effects of good surface structure stability, efficient preparation method, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

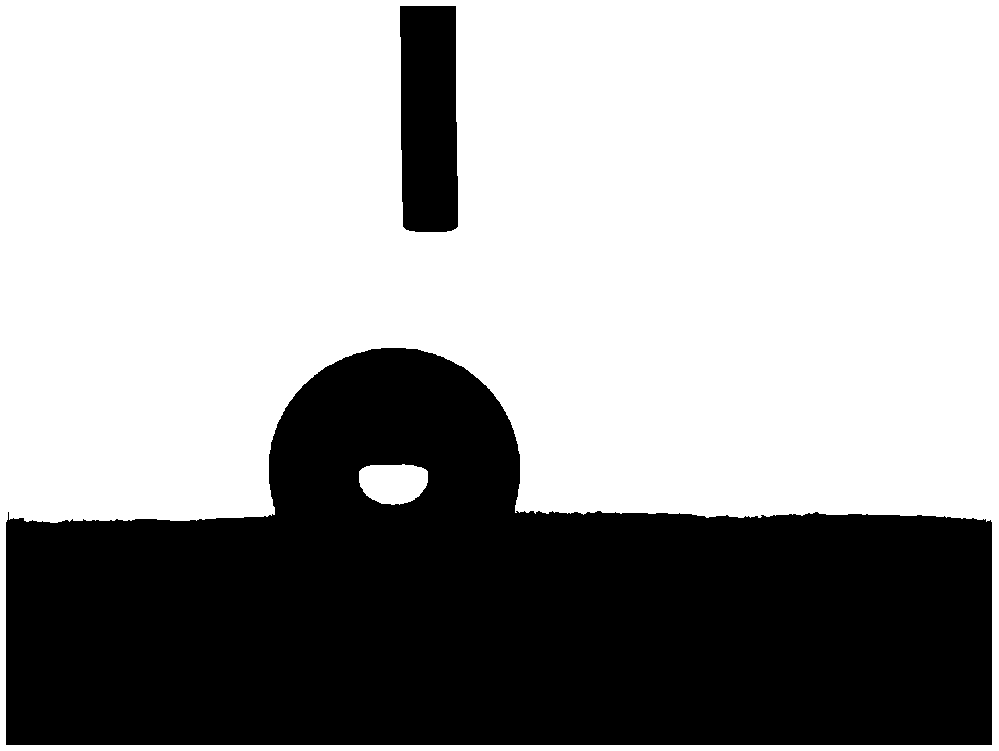

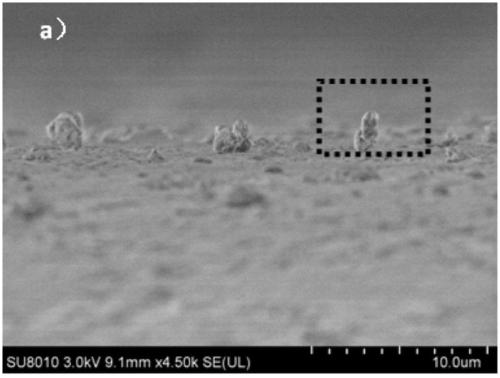

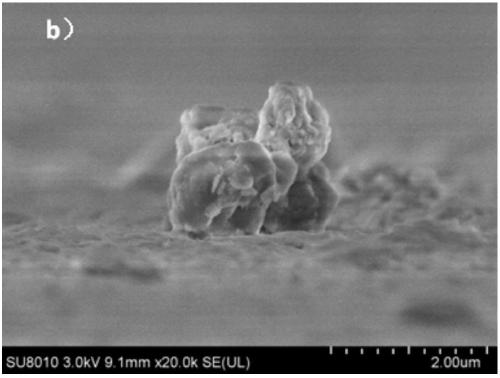

[0027] Weigh 17.6mg of iPP-b-PEG (the number average molecular weight of the iPP segment is 7800g / mol), the number average molecular weight of the PEG segment is 2300g / mol, put it in a 5mL volumetric flask, add n-octane to the mark, Heat to 110°C to dissolve the polymer completely, and then use a spin coater to spin coat the polymer solution on the surface of a clean polypropylene film (the water contact angle of the polypropylene film itself is 100°). Finally, the surface-modified polypropylene film is vacuum-dried in a vacuum oven and the volatilized solvent is recovered to obtain a superhydrophobic polypropylene film. Adopt OCAH200 contact angle tester to test the wettability of this film surface, the result shows that the contact angle of this surface and water is 153 °, and rolling angle is less than 10 °, as figure 1 . The surface morphology of the film was observed with a Sirion-100 field emission scanning electron microscope, and it was found that there was a micro-na...

Embodiment 2

[0029] Weigh 17.6 mg of iPP-b-PEG (the number average molecular weight of the iPP segment is 6500g / mol), the number average molecular weight of the PEG segment is 2300g / mol, put it in a 5mL volumetric flask, add n-octane to the mark, Heat to 110°C to dissolve the polymer completely, and then use a spin coater to spin coat the polymer solution on the surface of a clean polypropylene film (the water contact angle of the polypropylene film itself is 100°). Finally, the surface-modified polypropylene film is vacuum-dried in a vacuum oven and the volatilized solvent is recovered to obtain a superhydrophobic polypropylene film. The wettability of the surface of the film was tested by OCAH200 contact angle tester, and the results showed that the contact angle of the surface with water was 151°, and the rolling angle was less than 10°. The results of hot fog experiments show that the obtained superhydrophobic polypropylene film has good surface structure stability.

Embodiment 3

[0031] Weigh 17.6 mg of iPP-b-PEG (the number average molecular weight of the iPP segment is 5500 g / mol), the number average molecular weight of the PEG segment is 2300 g / mol, put it in a 5 mL volumetric flask, add n-octane to the mark, Heat to 110°C to dissolve the polymer completely, and then use a spin coater to spin coat the polymer solution on the surface of a clean polypropylene film (the water contact angle of the polypropylene film itself is 100°). Finally, the surface-modified polypropylene film is vacuum-dried in a vacuum oven and the volatilized solvent is recovered to obtain a super-hydrophobic polypropylene film. The wettability of the surface of the film was tested by OCAH200 contact angle tester, and the results showed that the contact angle of the surface with water was 146°, and the rolling angle was less than 10°. The results of hot fog experiments show that the obtained superhydrophobic polypropylene film has good surface structure stability.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com