Red titanium dioxide photoelectrode with wedge-shaped structure and preparing and application of red titanium dioxide photoelectrode

A titanium dioxide and photoelectrode technology, applied in chemical instruments and methods, water treatment of special compounds, light water/sewage treatment, etc., can solve the problems of limited application range, poor light absorption capacity and utilization rate, etc., to achieve a firm combination and improve Light absorbing ability, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

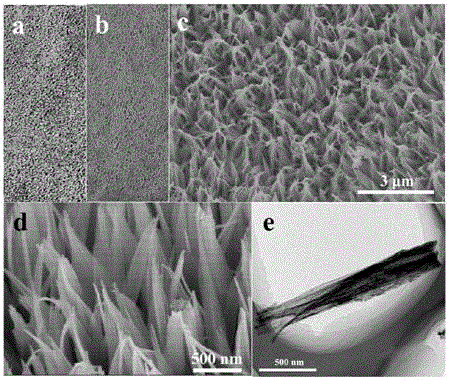

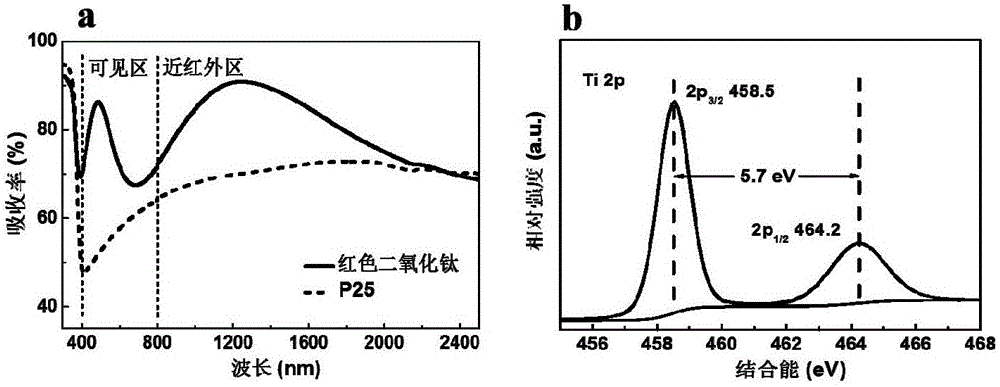

[0029] Example 1 A red titanium dioxide photoelectrode with a wedge-shaped structure and its preparation method

[0030] (1) Pretreatment of foamed titanium: Put the foamed titanium (titanium sheet) into a mixed solution containing isopropanol, acetone and deionized water (volume ratio 1:1:1) and ultrasonicate for 1 hour to remove the foamed titanium (titanium sheet) Remove impurities such as oil stains on the surface of the sheet), take out the foamed titanium (titanium sheet), wash it with deionized water for 6 times, and dry it in an oven at 80°C for use.

[0031] (2) Preparation of photoelectrodes: at room temperature

[0032] ①Put two pieces of pretreated titanium foam (2cm×4cm×1mm) on two sides containing 4mol·L -1 Sodium hydroxide solution in the polytetrafluoroethylene lining, sealed and placed in the reaction kettle, and then placed in a 180°C oven for 4h and 24h respectively;

[0033] ② After the reaction, open the reaction kettle, take out two pieces of foamed tit...

Embodiment 2

[0041] Example 2 A preparation method of a red titanium dioxide photoelectrode with a wedge-shaped structure

[0042] (1) Pretreatment of foamed titanium: immerse the foamed titanium (titanium sheet) in a mixed solution containing isopropanol, acetone and deionized water (volume ratio 1:1:1) for 1 h to remove the foamed titanium (titanium sheet) ) on the surface, then take out the foamed titanium (titanium sheet), wash it 10 times with deionized water, and dry it in an oven at 80°C for use;

[0043] (2) Preparation of photoelectrodes: at room temperature

[0044] ①Immerse a piece of pretreated titanium foam (2cm×4cm×1mm) in a solution containing 4mol L -1 In the polytetrafluoroethylene lining of sodium hydroxide solution, put it into the reaction kettle after sealing, and then put it in an oven at 180 ° C for 5 hours;

[0045] ② After the reaction, take out the foamed titanium, wash it with deionized water and place it in 2mol·L -1 Nitric acid solution for 36 hours, and the...

Embodiment 3

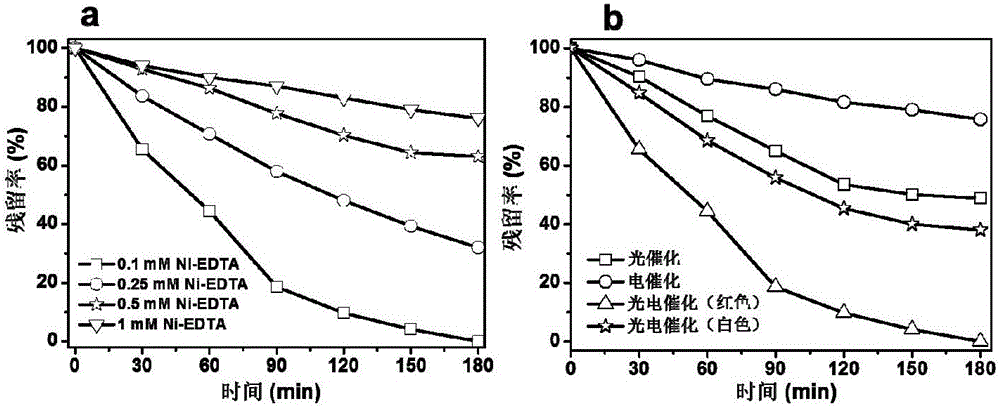

[0047] Example 3 Application of a red titanium dioxide photoelectrode with a wedge-shaped structure

[0048] Assembly of the photocatalytic degradation system: the red titanium dioxide prepared in Example 1 was used as the anode, the cleaned and dried titanium sheet was used as the cathode, and the high-pressure xenon lamp was used as the light source to degrade pollutants by photocatalysis.

[0049] The distance between the anode and the cathode is 1.5 cm, and the distance between the light source and the anode is 8 cm. The effective illumination area of the anode is 5cm 2 . The photoelectrochemical reactor is equipped with 70mL of the solution to be degraded. In order to disperse the pollutants evenly, the whole experimental process is carried out under the condition of constant stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com