Anti-skidding anti-deflecting cleaning device of belt conveyor

The technology of a belt conveyor and a cleaning device is applied in the field of cleaning machinery, which can solve the problems of increasing labor intensity of workers, production loss, inconvenience, etc., and achieve the effects of reducing production accidents, improving production efficiency, and improving cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

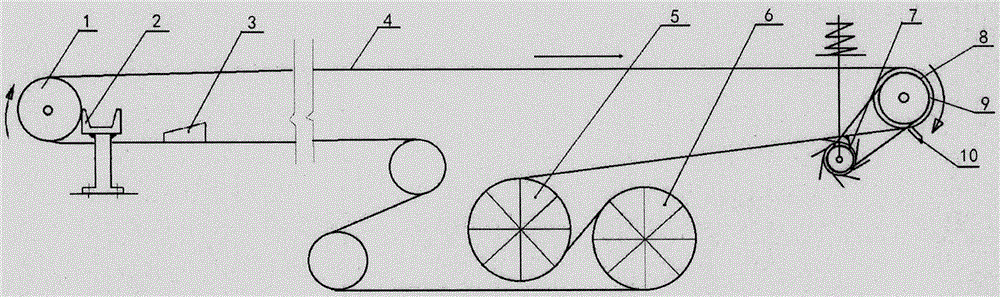

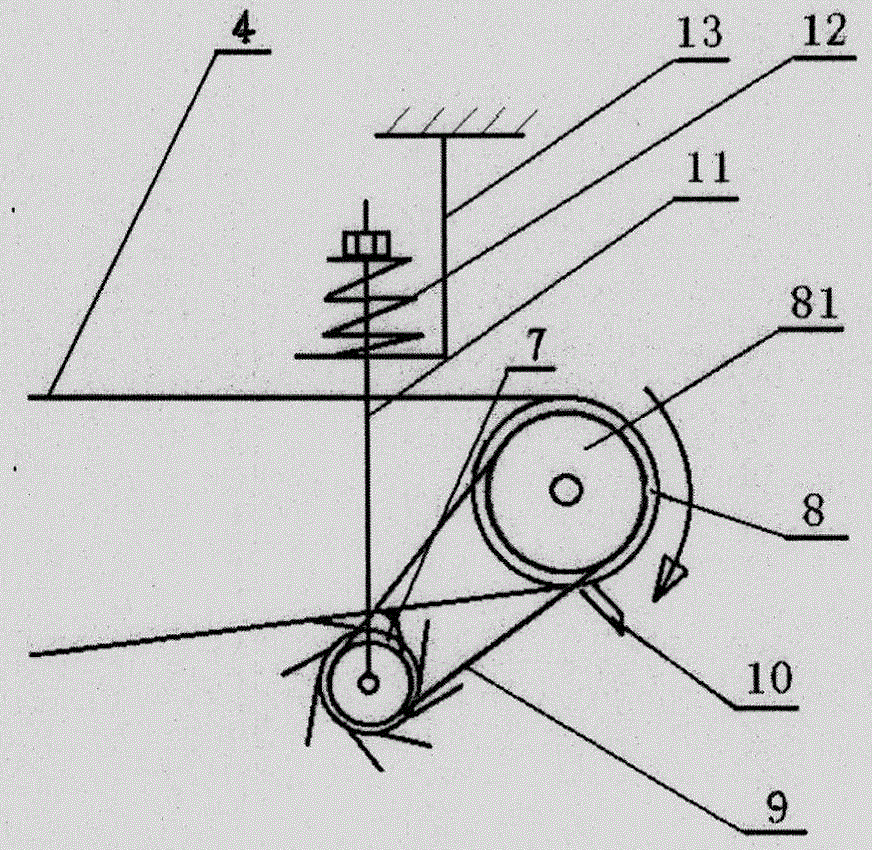

[0015] Attached below figure 1 And attached figure 2 , the present invention is described in detail.

[0016] An anti-skid and anti-deviation cleaning device for a belt conveyor, which is composed of two parts: a machine head cleaner (7) and a tail roller cleaner (2). From the perspective of use effect, the present invention can completely replace the original cleaner: Head sweeper (10) and former tail sweeper (3), but consider that the old sweeper has been installed mostly on the spot, can keep in principle, the present invention mainly completes the task of sweeping water and further strengthening cleaning effect, like this , The old and new devices work at the same time, which can also prolong the service life of the present invention.

[0017] The nose cleaner (7) is a ratchet-shaped cylinder with elastic surface, the shaft of the ratchet-shaped cylinder rotates around one end of the pull rod (11) with spring (12), and the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com