Oil-phase composition for generating water-in-oil liquid drops with centrifugation method

A composition, water-in-oil technology, which is used in laboratory containers, microorganism determination/inspection, transportation and packaging, etc., can solve the problem that the thermal stability of droplets cannot reach PCR reaction temperature conditions, etc., and achieve a convenient method. , low cost, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

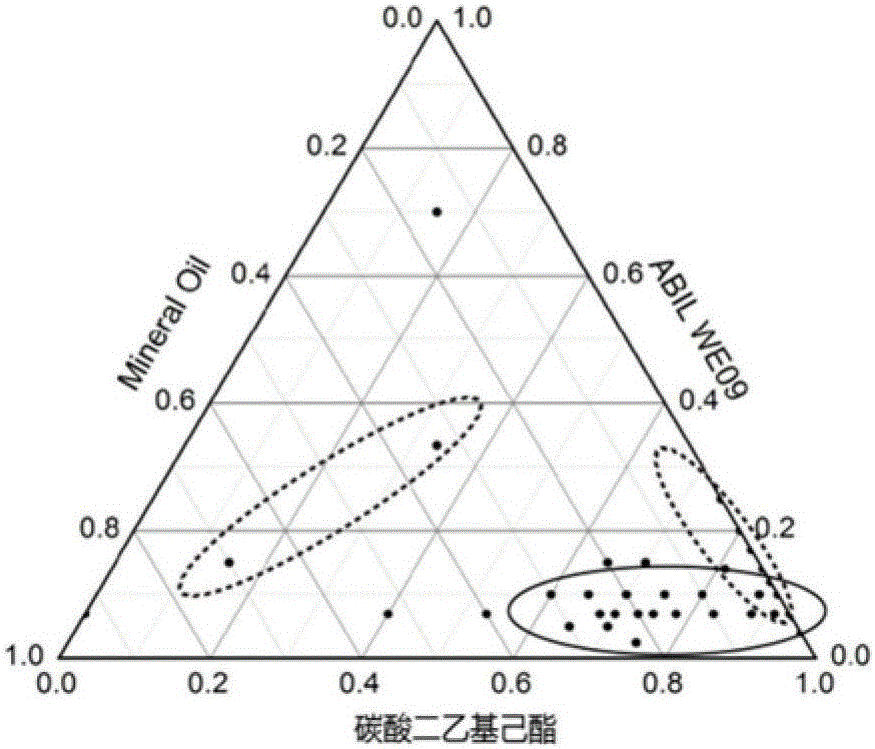

[0019] The first liquid is PCR reaction liquid, its composition is: 1×PCR buffer, 5mM MgCl 2 , 0.4 mM dNTPs, 1% Platinum Taq Polymerase. On the basis of using the combination of carbonic acid diester, mineral oil and surfactant as the oil phase composition in the prior art to adjust the amount of each component, in order to find the one that meets the requirements of density and thermal stability, it can react with PCR by centrifugation The ratio of the oil phase composition of the liquid to obtain a stable emulsion system. The component contents of Examples 1-34 are shown in Table 1.

[0020] The oil phase composition formula (v / v) of table 1 embodiment 1-34

[0021]

[0022]

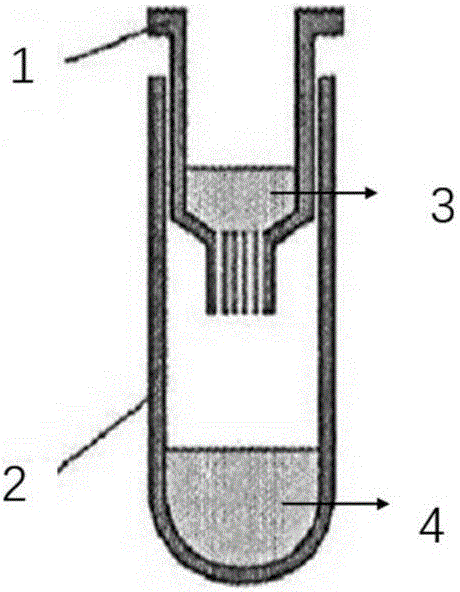

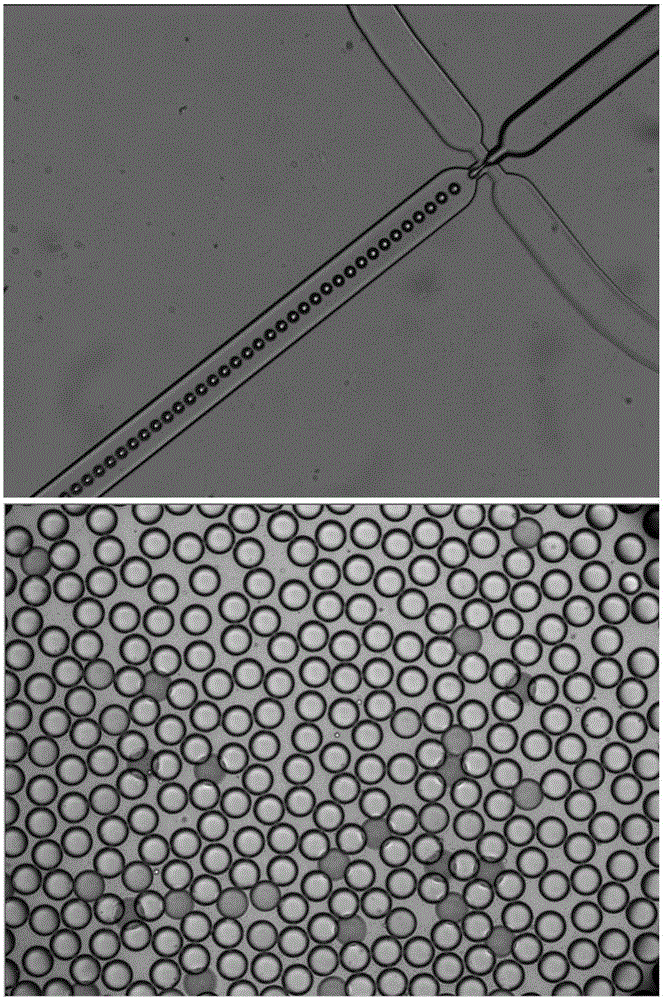

[0023] Use the generating device of the droplet in CN 104741158 A (such as figure 1 Shown), wherein reference numeral 1 is a droplet tube, 2 is a collecting tube, 3 is a first liquid, and 4 is a second liquid. The PCR reaction solution is used as the first liquid, and the oil phase mixture in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com