Composite metal oxide loaded Pt-based nano metal catalyst and preparation method therefor

A composite metal and nano-metal technology, which is used in metal/metal oxide/metal hydroxide catalysts, preparation of organic compounds, preparation of hydroxyl compounds, etc. large and other problems, to achieve the effects of excellent catalytic performance, improved structural stability, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

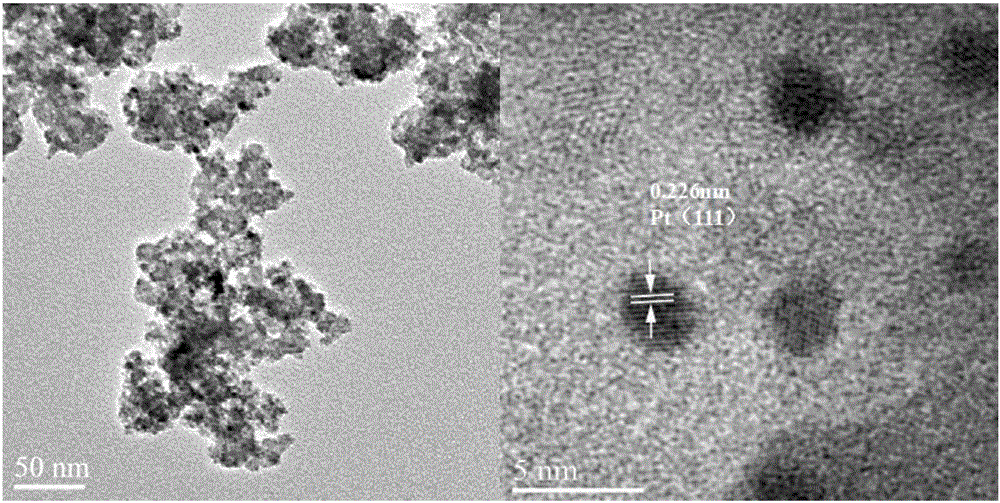

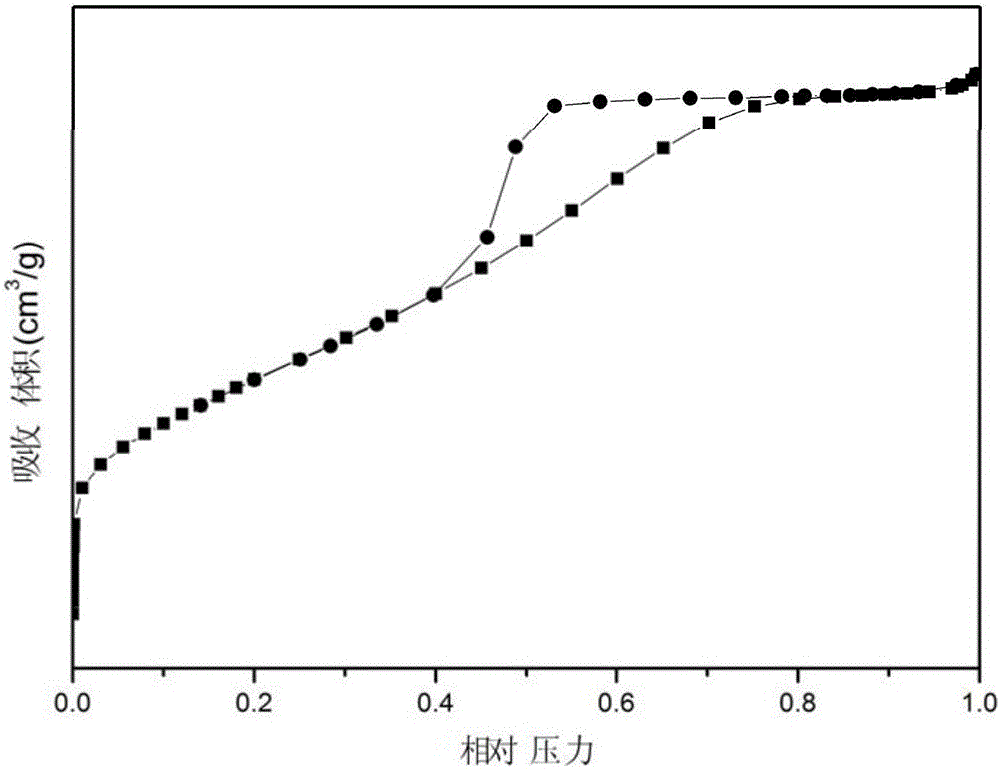

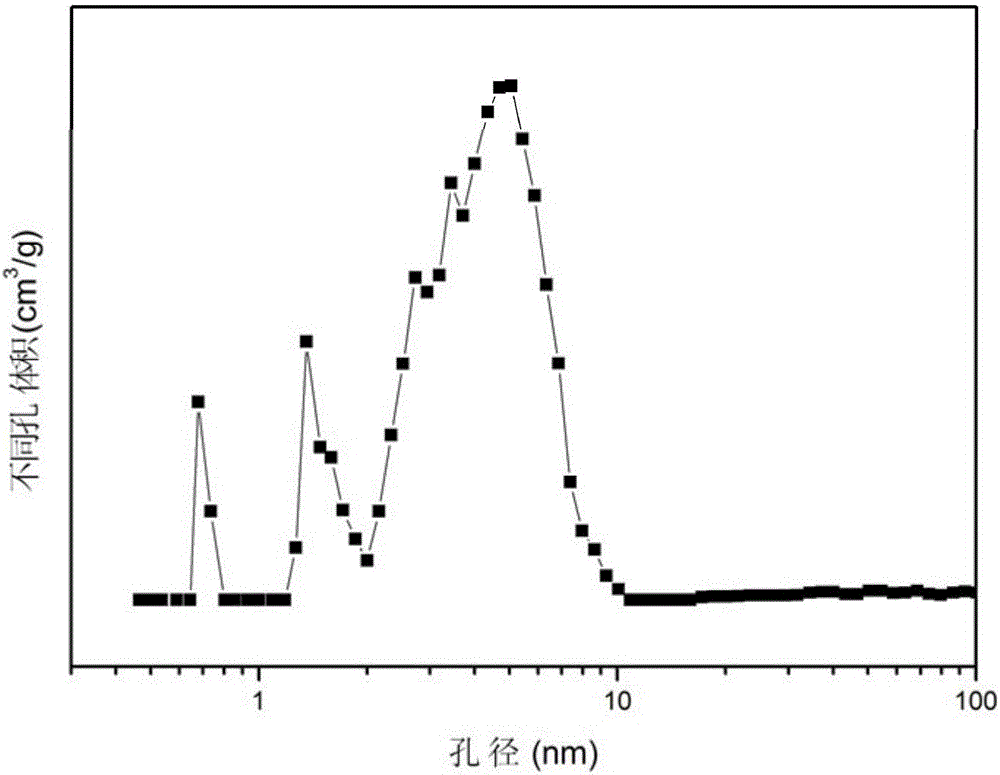

[0018] Use deionized water to prepare mixed salt solution of zirconium nitrate and cerium nitrate, chloroplatinic acid solution and potassium borohydride solution, wherein the concentration of zirconium nitrate solution is 0.0625mol / L, the concentration of cerium nitrate solution is 0.0625mol / L, and the concentration of chloroplatinic acid solution is 0.0625mol / L. It is 0.005mol / L, the concentration of potassium borohydride is 0.75mol / L, and the tetravalent metal salt solution, chloroplatinic acid solution and potassium borohydride solution are added to the colloid mill at the same time in a volume ratio of 1:1:2 at 6000rpm. It was fully stirred for 5 min to make it nucleate rapidly, and then the reacted solution was transferred to a hydrothermal reactor, crystallized at 150 °C for 24 h, then centrifuged and washed to neutrality, and finally vacuum dried at 70 °C to obtain CeO 2 -ZrO 2 Composite metal oxide-supported Pt-based nanometal catalysts. The catalyst has a surface ar...

Embodiment 2

[0021] The mixed solution of cerium nitrate and titanium tetrachloride, chloroplatinic acid solution and potassium borohydride solution were prepared with deionized water, wherein the concentration of cerium nitrate solution was 0.125mol / L, the concentration of titanium tetrachloride solution was 0.125mol / L, and the concentration of chlorine tetrachloride solution was 0.125mol / L. The concentration of platinum acid solution is 0.008mol / L, and the concentration of potassium borohydride is 1mol / L. The tetravalent metal salt solution, the chloroplatinic acid solution and the potassium borohydride solution were added to the colloid mill at the same time in a volume ratio of 1:1:2 and fully stirred at 6500 rpm for 8 minutes to make it rapidly nucleated, and then the solution after the reaction was transferred. In a hydrothermal reactor, hydrothermally reacted at 120 °C for 32 h, then centrifuged and washed until neutral, and finally vacuum-dried at 80 °C to obtain CeO 2 -TiO 2 Pt-b...

Embodiment 3

[0024] Use deionized water to prepare mixed solution of titanium tetrachloride and zirconium nitrate, chloroplatinic acid solution and potassium borohydride solution, wherein the concentration of titanium tetrachloride solution is 0.1mol / L, the concentration of zirconium nitrate solution is 0.1mol / L, and the concentration of chloroplatinum is 0.1mol / L. The concentration of the acid solution is 0.0039mol / L, and the concentration of potassium borohydride is 1.0mol / L. The tetravalent metal salt solution, the chloroplatinic acid solution and the potassium borohydride solution are added to the colloid mill at the same time in a volume ratio of 1:1:2. The solution was fully stirred at 6000 rpm for 5 min to make it nucleate rapidly, and then the reacted solution was transferred to a hydrothermal reaction kettle, hydrothermally reacted at 150 °C for 24 h, then centrifuged and washed until neutral, and finally vacuum-dried at 70 °C, get ZrO 2 -TiO 2 Pt-based nanometal catalysis suppor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com