Granular cellulose filter aid applied to titaniferous solution filter in production of titanium oxide

A production process and filter aid technology, applied in other chemical processes, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve problems such as affecting production efficiency, dust, and inability to settle, saving transportation and storage Cost, easy to promote and apply, easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

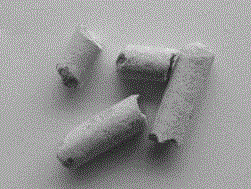

[0011] Example 1: Prepare the powdered organic fiber filter aid into a cylindrical particle filter aid with a length of 1 to 3 cm and a diameter of 0.6 cm, and use the amount of the original powdered cellulose filter aid for titanium dioxide addition, filtration and precoating Filtration, feeding and stirring time can be shortened from 30 minutes to 10 minutes, and feeding dust can be completely eliminated. The storage space for 1t of granular cellulose products can be changed from the original 1.5cm 3 storage space is reduced to 0.3 cm 3 .

Embodiment 2

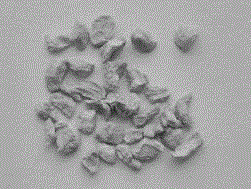

[0012] Embodiment 2: the powdery organic fiber filter aid is prepared into 0.5 ~ 1cm long, wide 0.3 ~ 0.6cm bean-shaped particle filter aid, according to the amount of the original powdery cellulose filter aid for titanium dioxide addition filtration and Pre-coating and filtering, the feeding and stirring time can be shortened from the original 30 minutes to 5 minutes, and the feeding dust can be completely eliminated. The storage space for 1t of granular cellulose products can be changed from the original 1.5cm 3 The storage space is reduced to 0.4cm 3 .

Embodiment 3

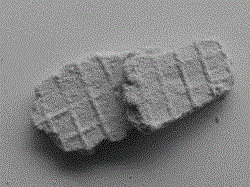

[0013] Example 3: Prepare the powdered organic fiber filter aid into a cake-shaped granular filter aid with a thickness of 0.3 to 6 cm, and use the amount of the original powdered cellulose filter aid for titanium dioxide addition filtration and pre-coating filtration, and add materials and stir The time can be shortened from 30 minutes to 8 minutes, which can significantly reduce the feeding dust. The storage space for 1t of granular cellulose products can be changed from the original 1.5 cm 3 storage space is reduced to 0.5 cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com