Three-dimensional circular weaving machine

A three-dimensional circular loom and host technology, used in circular looms, looms, textiles, etc., can solve the problems of unclear opening, high cost, and large number of warp yarns, reduce the amount of waste yarn in the process, improve product quality, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

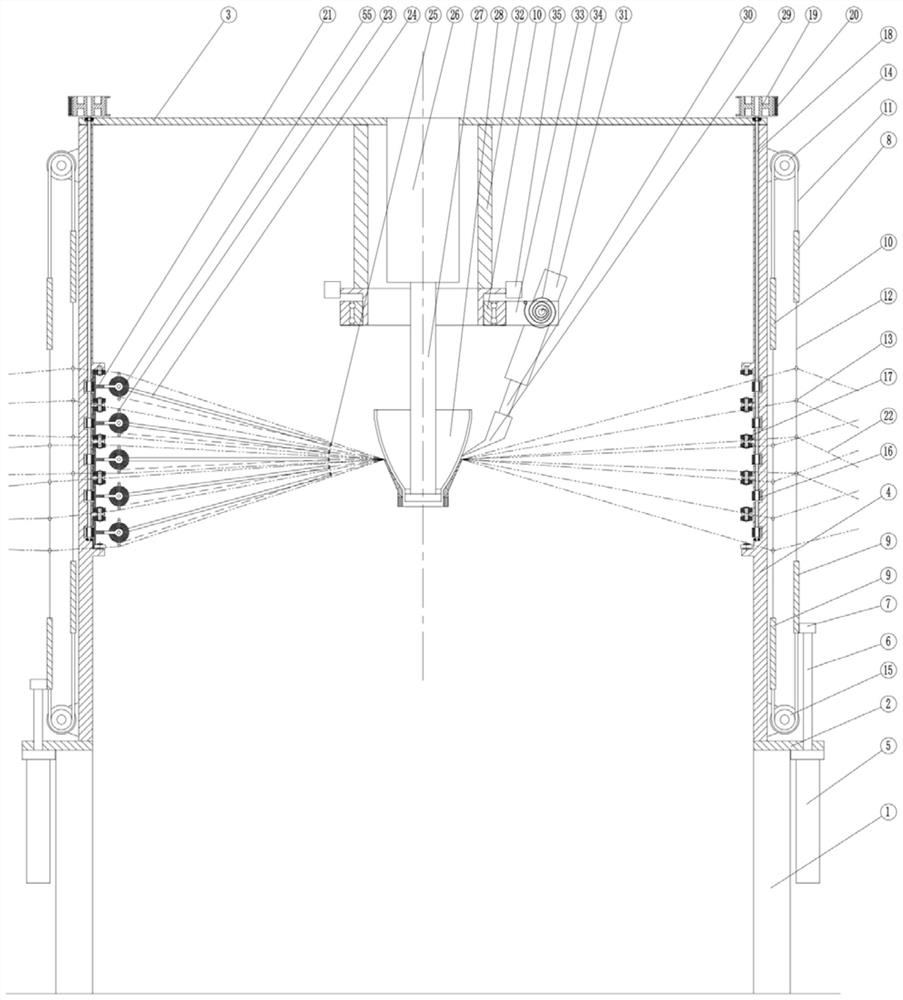

[0087] see figure 1 , figure 2 , a 2.5D single-row 5-shuttle three-dimensional circular loom with i=1, comprising a main engine, a warp creel, and a warp yarn tension component, the warp creel is distributed around the main engine, and a warp yarn tension component is arranged in the middle of the warp creel and the main body, and the warp yarns extend from the warp creel. The yarn bobbin is drawn out and sent to the host through the warp tension component;

[0088] The main machine includes a frame, an opening device, a weft insertion device, a tightening device, a core mold driving device, a driving motor and a control device. This machine can weave 5 layers of warp yarns and 8 sets of warp yarns with shallow interlocking veilless 2.5D three-dimensional tubular fabrics.

[0089] The frame includes a column 1, an upper support plate 3 and a lower support plate 2 and a group of support columns 4 distributed on the same circle to connect the upper support plate and the lower...

Embodiment 2

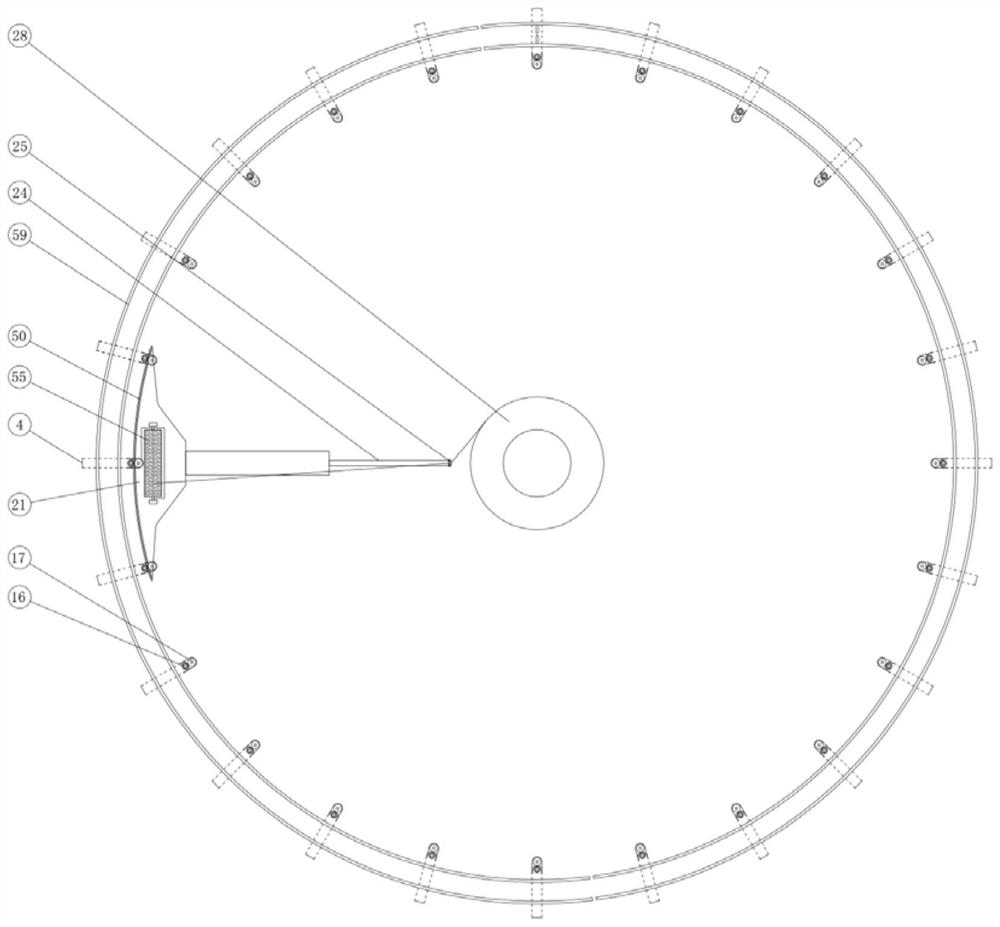

[0097] see Figure 9 , a 3D three-dimensional circular loom with i=1, comprising a main engine, a warp creel, and a warp yarn tension component, the warp creel is distributed around the main engine, and a warp yarn tension component is arranged in the middle of the warp creel and the main engine, and the warp yarn is drawn out from the bobbin of the warp creel , sent to the host through the warp tension component; the host includes a frame, an opening device, a weft insertion device, a tightening device, a core mold driving device, a driving motor and a control device.

[0098] The frame includes a column 1, an upper support plate 3 and a lower support plate 2 and a group of support columns 4 distributed on the same circle to connect the upper support plate and the lower support plate;

[0099]The opening device includes 2m semi-circular heald frames 59 coaxially distributed, 2m lifters and heald frame limit slots arranged on the support column 4, where m is the number of warp...

Embodiment 3

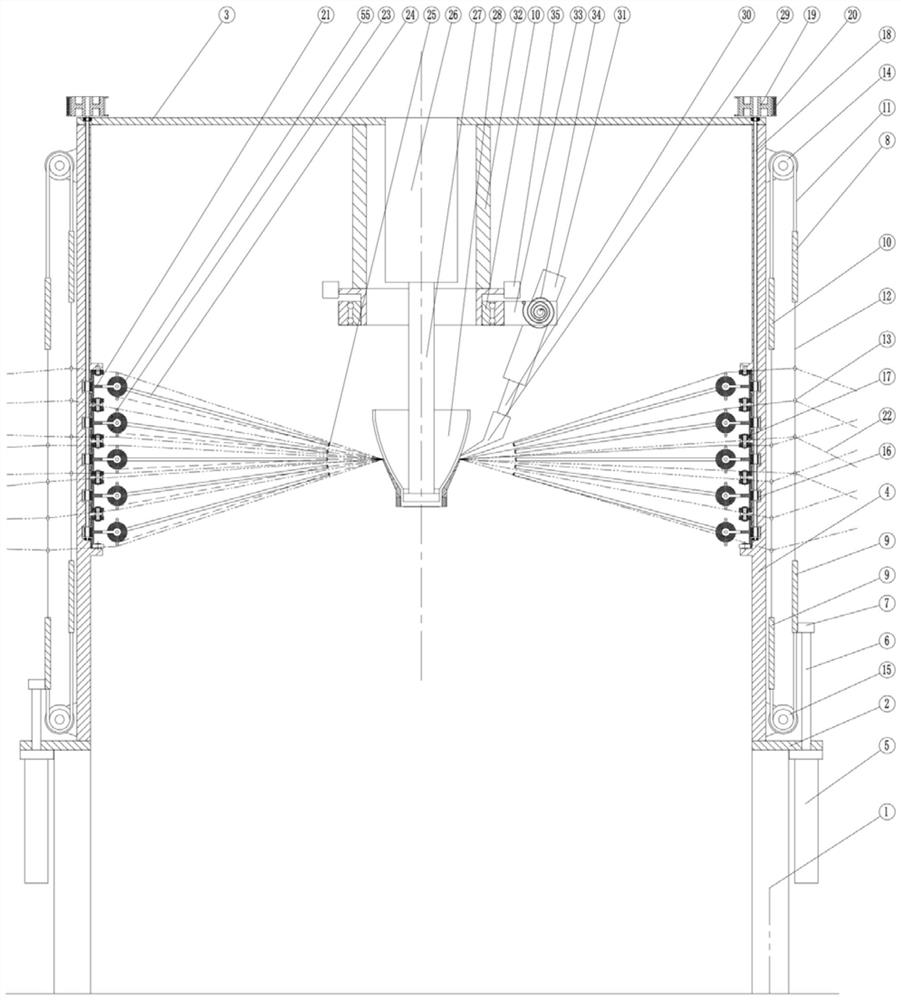

[0106] see image 3 , Figure 4 , an enhanced 2.5D three-dimensional circular loom with i=2, comprising a main engine, a warp creel, and a warp yarn tension assembly, the warp creel is distributed around the main engine, and a warp yarn tension assembly is arranged in the middle of the warp creel and the main engine, and the warp yarn from the warp creel The yarn bobbin is drawn out and sent to the host through the warp tension component; the host includes a frame, an opening device, a weft insertion device, a tightening device, a mandrel driving device, a driving motor and a control device.

[0107] The frame includes a column 1, an upper support plate 3 and a lower support plate 2 and a group of support columns 4 distributed on the same circle to connect the upper support plate 3 and the lower support plate 2;

[0108] The opening device includes 8 semicircular heald frames 59 in total, 4 or 2 lifters 5 and a heald frame limit slot set on the support column 4, 8 semicircula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com