Manufacturing process of carbon fiber heating steering wheel

A carbon fiber heating and manufacturing process technology, applied in steering control, steering control mounted on a car, steering mechanism, etc., can solve the problems of low thermoelectric conversion rate of metal resistance wire, uneven heating of the steering wheel body, etc. The effect of enhancing comfort

Inactive Publication Date: 2021-04-06

JIAXING FANGSUN ELECTRONICS & TECH

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the traditional resistance wire is wound on the steering wheel body, which will cause uneven heating of the s

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a manufacturing process of a carbon fiber heating steering wheel. The manufacturing process is characterized by comprising the following specific steps: a, forming a steering wheel metal framework; b, foaming an inner foaming layer on the steering wheel framework; c, uniformly coating the inner foaming layer of a steering wheel with heating cloth; and d, forming an outer foaming layer on the outer surface of the heating cloth, so that the heating cloth is positioned between the inner foaming layer and the outer foaming layer. The process has a uniform heating effect and an efficient heat conversion rate, meanwhile, the heating cloth has a far infrared heating effect, and the blood circulation of blood capillaries of palms is facilitated.

Description

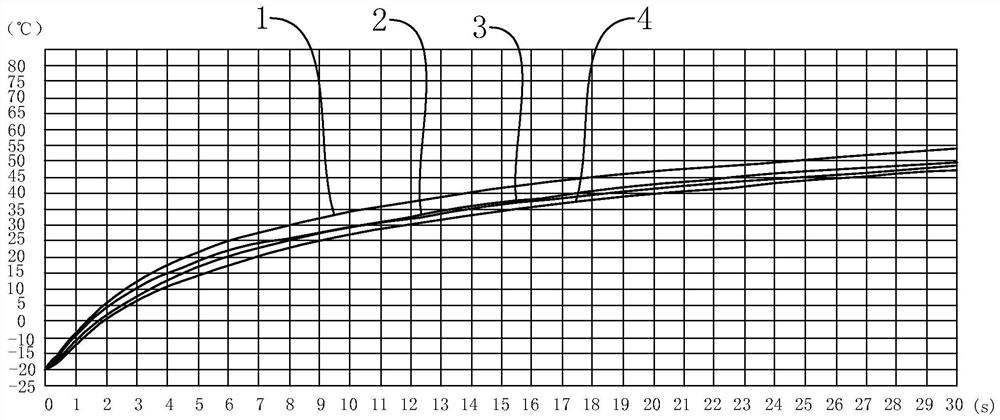

Technical field[0001]The present invention relates to the field of vehicle steering wheel, and more particularly to a carbon fiber heating steering wheel making process.Background technique[0002]When the vehicle is just starting the vehicle, since the engine temperature rise is slow, the car air conditioner can't immediately blow out the warm air, the steering wheel is cold, affecting the driver's driving hand and comfort.[0003]For this existing vehicle, there is provided a directional disc electrolyte heating device, which is mainly composed of a metal resistor wire, a temperature control module, a temperature sensor, a control switch, or the like, and is controlled by the metal resistance wire, and controls by temperature sensor. Steering wheel temperature. However, the conventional resistance wire is wound on the steering wheel body, which causes the steering wheel body to be lowered uneven when heated, and the thermoelectric conversion rate of the metal resistance wire is relati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B62D1/06

CPCB62D1/065

Inventor 林楚鹤孙东张文广刘旭平

Owner JIAXING FANGSUN ELECTRONICS & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com