Three-in-one washing kettle for preparing chlorinated polyethylene

A chlorinated polyethylene, three-in-one technology, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve the problem of increasing production floor area and equipment maintenance costs, prolonging chlorination Polyethylene production cycle, increased material transfer time and other issues, to achieve the effect of saving material transfer time, reducing equipment maintenance costs, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

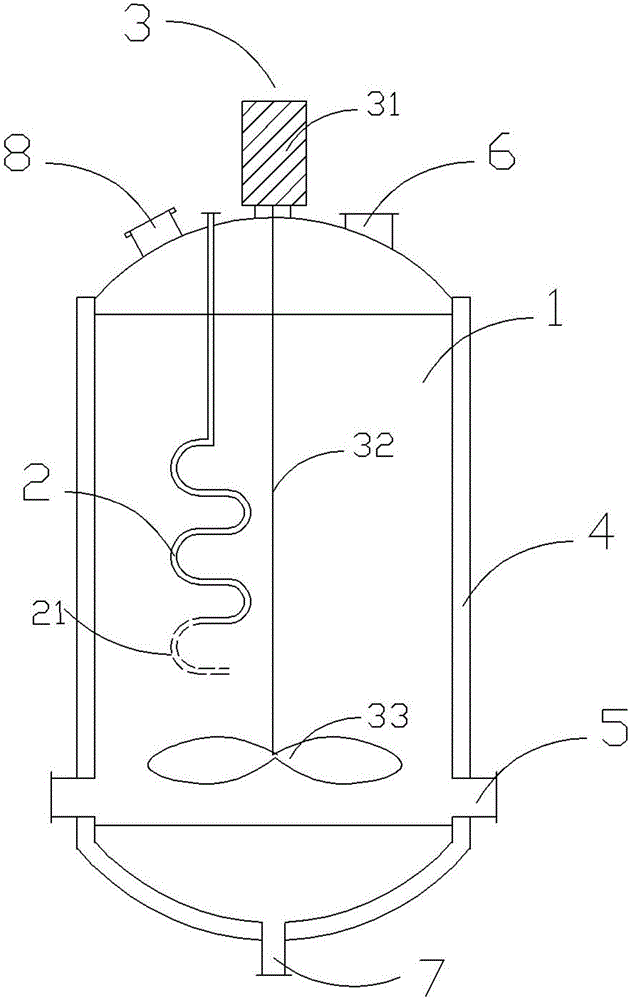

[0021] A three-in-one washing kettle for preparing chlorinated polyethylene of the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

[0022] figure 1 A schematic structural diagram of a three-in-one washing kettle for preparing chlorinated polyethylene of the present invention is shown.

[0023] An embodiment of a three-in-one washing kettle for preparing chlorinated polyethylene of the present invention, such as figure 1 As shown, the three-in-one washing kettle includes a tank body 1, a heating coil 2 and a stirring device 3, wherein the outside of the tank body 1 is covered with a thermal insulation layer 4, preferably, the thermal insulation layer is made of mineral wool or Made of expanded pearl cotton, it is used for heat preservation when heating the materials in the tank and reduce energy loss; the inner wall of the tank is provided with a high temperature and corrosion resistant layer, such as a g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com