A kind of mems device preparation method

A device and component technology, applied in the field of MEMS devices and their preparation, can solve the problems of the decrease of the signal-to-noise ratio and sensitivity of the MEMS microphone, the decrease of the effective stiffness of the MEMS microphone backplane, the decrease of the effective stiffness of the backplane and the backplane, etc. The effect of meeting performance requirements and avoiding resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] In order to solve the problems existing in the prior art, a MEMS device is provided, and the MEMS device will be further described below in conjunction with the accompanying drawings, wherein Figure 1g A schematic structural diagram of a MEMS device in a specific embodiment of the present invention.

[0057] First, refer to Figure 1g , the MEMS device comprising:

[0058] semiconductor substrate 101;

[0059] A backplane 103, located above the semiconductor substrate, wherein the backplane is provided with several spaced through holes;

[0060] The diaphragm 105 is located above the backboard;

[0061] a sacrificial layer, located between the diaphragm 105 and the back plate 103;

[0062] Wherein, a cavity is formed between the diaphragm 105 and the back plate 103 , and several back cavities are formed in the semiconductor substrate below the cavity.

[0063] The MEMS device described in the present invention is a MEMS microphone.

[0064] In the MEMS microphone...

Embodiment 2

[0082] The present invention also provides a kind of preparation method of described MEMS device, below in conjunction with Figures 1a-1g To further illustrate the method, the above 1a-1g are schematic diagrams of the fabrication process of the MEMS device in this embodiment.

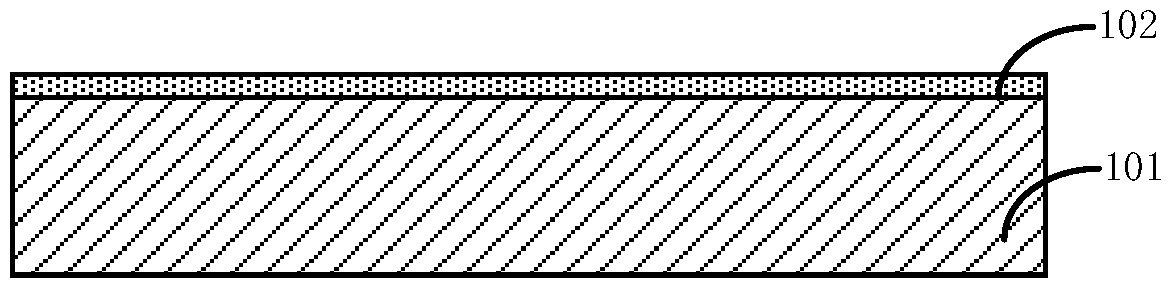

[0083] First, step 201 is performed to provide a semiconductor substrate 101 and form an insulating layer 102 on the semiconductor substrate 101 .

[0084] Specifically, such as Figure 1a As shown, in this step, the semiconductor substrate 101 can be at least one of the materials mentioned below: silicon, silicon-on-insulator (SOI), silicon-on-insulator (SSOI), and germanium-on-insulator Silicon (S-SiGeOI), silicon germanium on insulator (SiGeOI) and germanium on insulator (GeOI), etc.

[0085] Then an insulating layer 102 is formed on the semiconductor substrate 101. Optionally, the insulating layer 102 may be SiN, but not limited to the material.

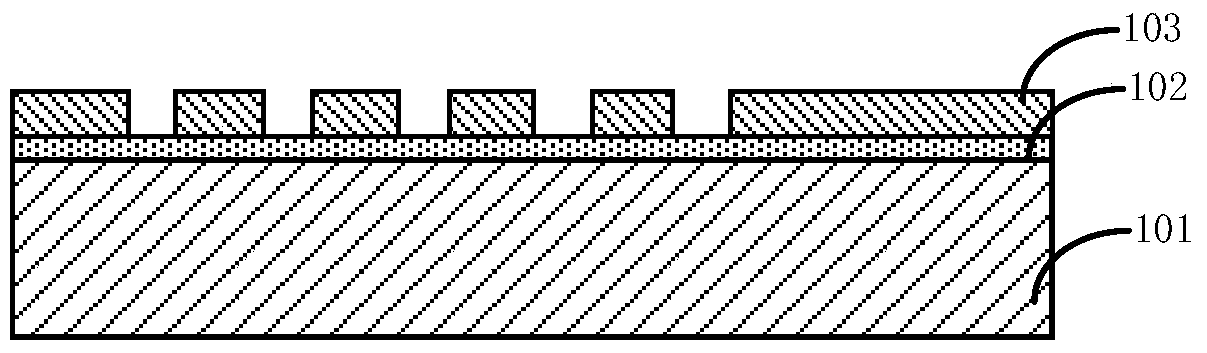

[0086] Step 202 is executed to form a backplane 1...

Embodiment 3

[0130] As an alternative implementation of the present invention, the positions of the back plate and the diaphragm can be interchanged, for example, the diaphragm is located above the semiconductor substrate, and the back plate is located on the side of the diaphragm. Above, several perforations are formed in the diaphragm, and several back cavities exposing the diaphragm are formed in the semiconductor substrate, and the diaphragm is supported by the intervals between the back cavities.

[0131] The MEMS device and the preparation method can refer to Embodiments 1 and 2, except that the positions of the back plate and the diaphragm are exchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com