Chip structure with bonding wire

A chip structure and chip technology, applied in semiconductor/solid-state device parts, semiconductor devices, electrical components, etc., can solve the problems of damaged joint strength, large stress concentration, copper wire is not easy to deform, etc., and achieve good joint strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

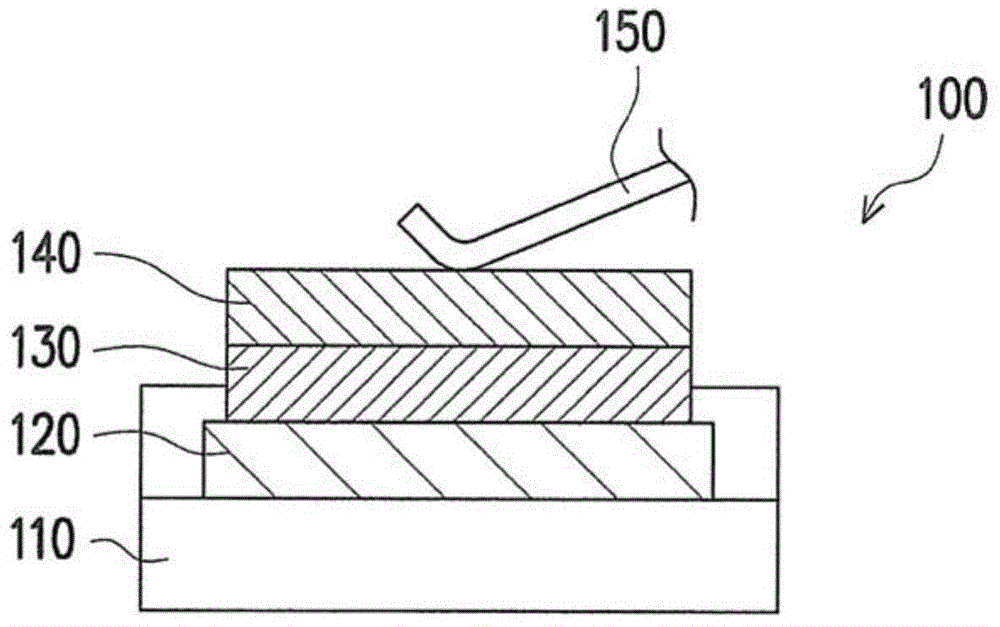

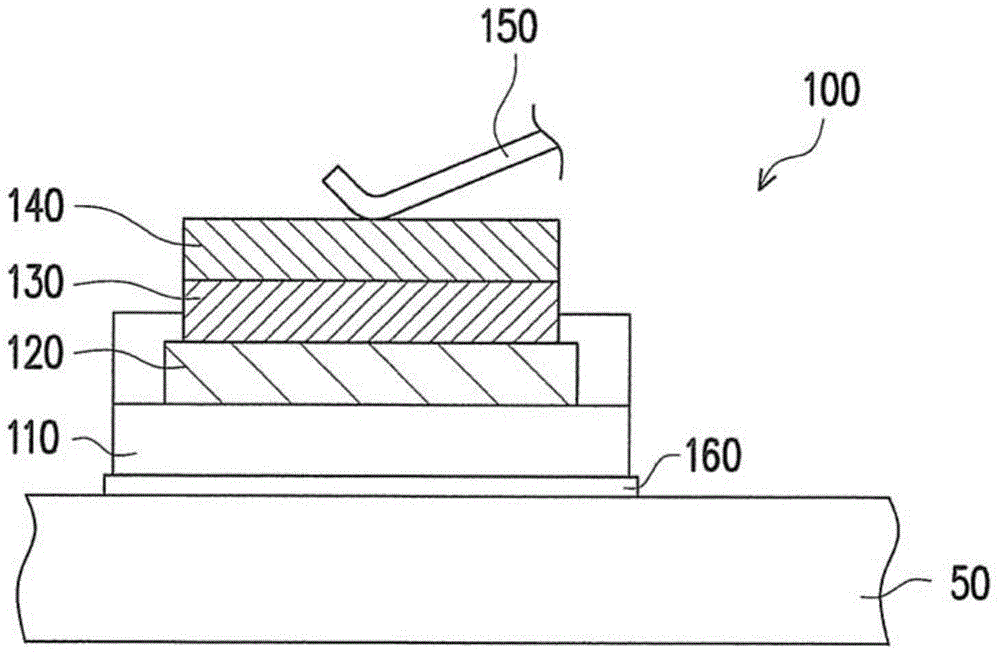

[0025] figure 1 It is a schematic diagram of the chip structure of an embodiment of the present invention. Please refer to figure 1 , the chip structure 100 of this embodiment includes a chip 110 , a first metal layer 130 , a second metal layer 140 and bonding wires 150 . The pads 120 are disposed on the chip 110 , and the first metal layer 130 is disposed on the chip 110 . The material of the first metal layer 130 is, for example, nickel or nickel alloy. The second metal layer 140 is disposed on the first metal layer 130 , and the material of the second metal layer 140 is, for example, copper, copper alloy, aluminum, aluminum alloy, palladium or palladium alloy. The bonding wire 150 is connected to the second metal layer 140 by, for example, a wedge bond manufacturing process. The material of the bonding wire 150 is, for example, copper or a copper alloy, and the wire diameter of the bonding wire 150 is, for example, larger than 102 microns to be suitable for high Power mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com