Measuring method for bonding force between polymeric substrate and metal coating

A metal coating and measurement method technology, which is applied in the measurement of metal coating and polymer bonding force, and the measurement of composite material interface bonding force, can solve the problems of inaccuracy and untrue measurement results, and achieve measurement accuracy control, real measurement results, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Steps:

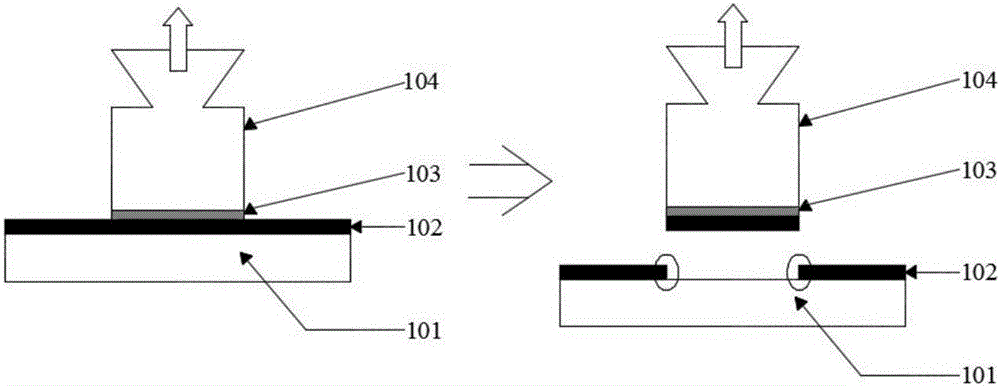

[0056] First place a metal sheet mask with the same size as the polymer substrate and a Φ15mm circular through hole in the center on the polyethylene terephthalate polymer substrate 1 with a size of 50mm×50mm×1mm 2;

[0057] Then, coat a layer of polyurethane 101 strong adhesive glue on the upper surface of the mask;

[0058] Using the vapor phase chemical deposition method, a metal silver coating 3 with a thickness of 2 μm is deposited on the upper surface of the mask plate and the exposed polymer layer in the area of the circular hole indiscriminately (that is, uniform in thickness). The metal silver coating 3 on the upper surface of the mask is bonded to the polyethylene terephthalate polymer 1, and the bonding position is the area to be tested for adhesion, and the metal silver coating on the upper surface of the mask is strongly adhered to the polyurethane 101. Consolidation with the mask under the action of gel glue;

[0059] Apply AMONIL-MMS with a th...

Embodiment 2

[0063] Except that the shape of the through hole is an equilateral triangle (the area of the equilateral triangle is equal to the area of the Φ15mm circular hole), all the others are the same as in Embodiment 1.

[0064] Measurement results: the adhesive force between the metallic silver coating 3 and the polyethylene terephthalate polymer substrate 1 was 87.06N.

Embodiment 3

[0066] Except that the shape of the through hole is a rhombus (the area of the rhombus is equal to the area of a Φ15mm circular hole), all the others are the same as in Embodiment 1.

[0067] Measurement results: the adhesive force between the metallic silver coating 3 and the polyethylene terephthalate polymer substrate 1 was 87.04N.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com