Turbo generator set vibration fault diagnosis method based on forward reasoning

A technology for steam turbine generator set and fault diagnosis, which is used in engine testing, data processing applications, electrical digital data processing, etc., and can solve problems such as low accuracy, compiled into computer language, and unreliable diagnosis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

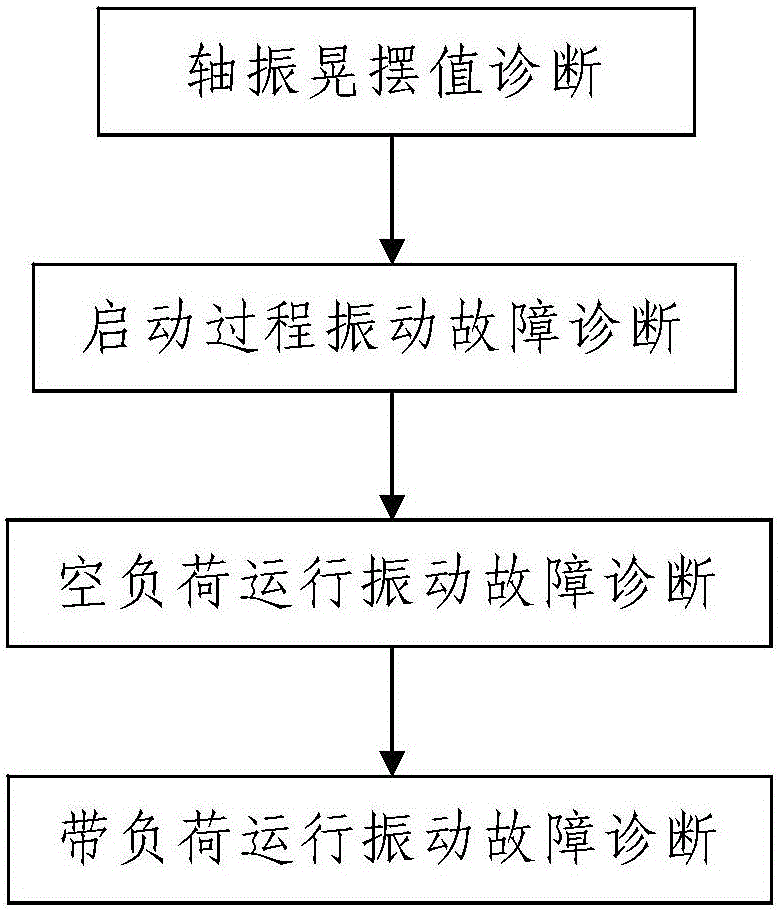

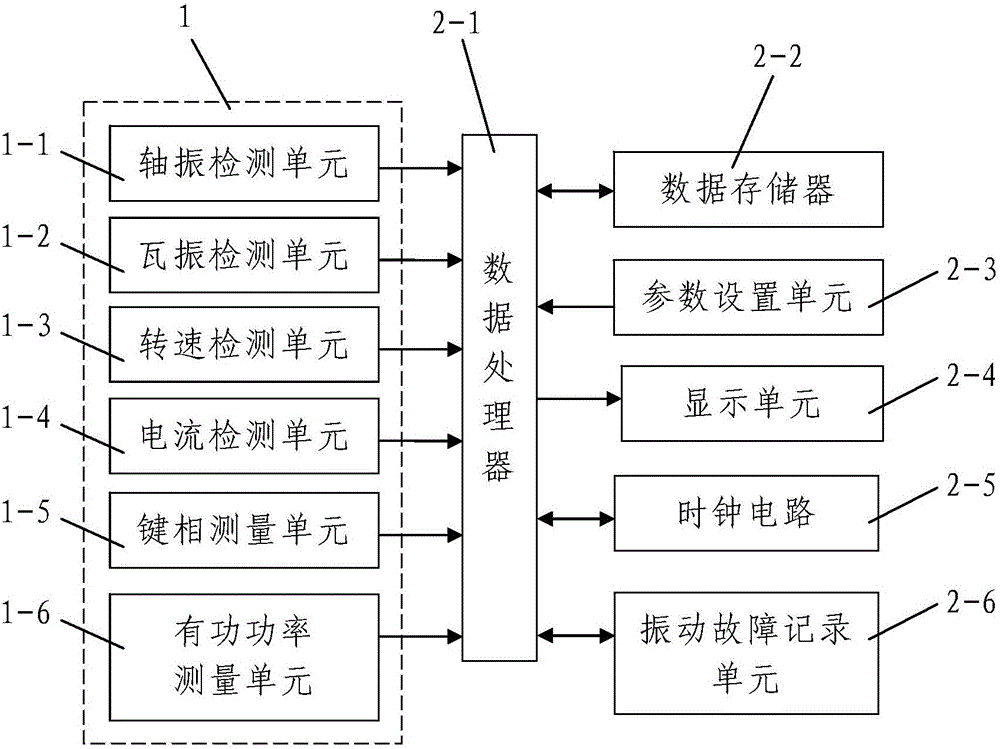

[0096] Such as figure 1 A vibration fault diagnosis method for a turbogenerator set based on forward reasoning is shown. After each startup and operation of the diagnosed turbogenerator set, the parameter detection device 1 is used to check the correlation between the startup and operation of the diagnosed turbogenerator set. The working parameters are detected in real time and the detection information is synchronously transmitted to the vibration fault diagnosis device 2 for automatic vibration fault diagnosis; the parameter detection device 1 includes a rotor working state for real-time detection of the working state of each rotor in the diagnosed steam turbine generator set Detection unit, speed detection unit 1-3 for real-time detection of the rotational speed of the diagnosed turbo-generator set, active power measurement unit 1-6 for measuring the active power of the diagnosed turbo-generator set, The key phase measurement unit 1-5 for the unit to measure the key phase a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com