Monoclinic-phase BiVO4/GO (graphene oxide)/RGO (reduced graphene oxide) crystal and preparation method thereof

A monoclinic phase, crystal technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve problems such as no reports, no patents and literature reports, and achieve the effect of good ionic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

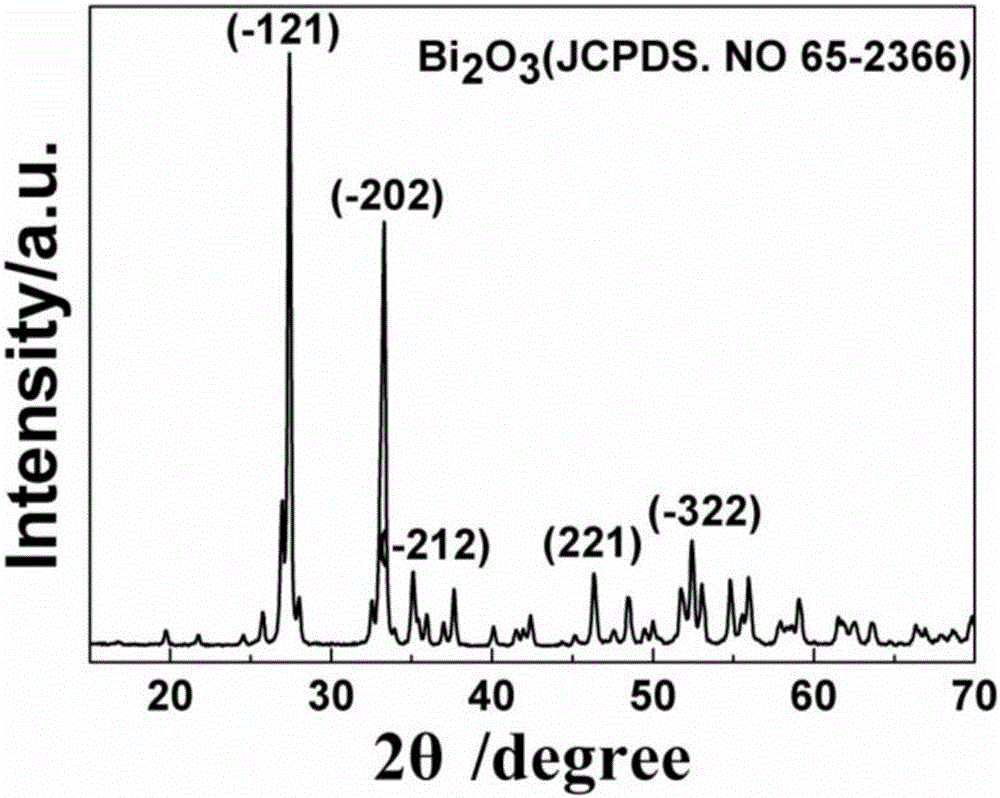

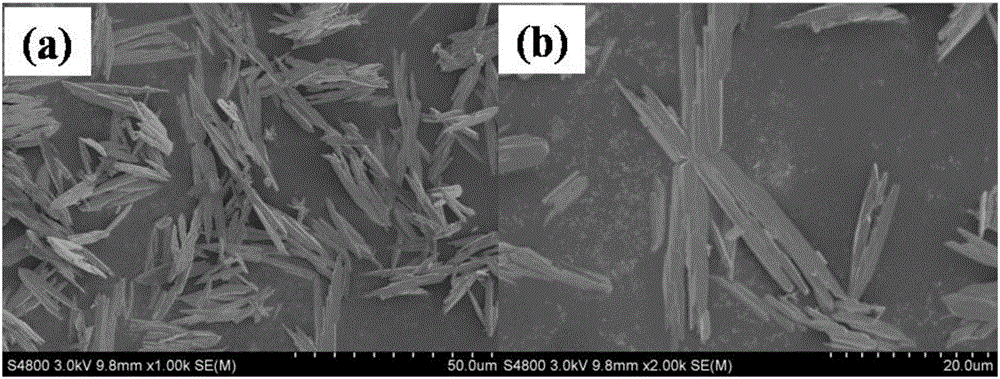

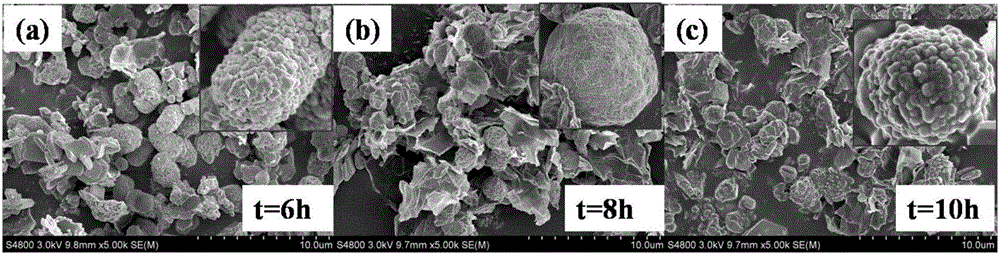

[0035] Step 1, 1mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 9 mL of 1mol / L dilute HNO 3 , stirred for 30 minutes, then added 3 mL of oleic acid, 3 mL of n-heptane and 10 mL of acetone dropwise at a rate of 2 drops / second, stirred for 10 minutes, and then added 5 mL of 10 mol / L NaOH solution at a rate of 2 drops / second to form Precursor solution, the precursor solution was stirred at room temperature for 8h to prepare Bi 2 o 3 Precipitate, wash and dry the precipitate for later use;

[0036] Step 2, 115mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in turn, stir at 0°C to obtain a mixed solution; then raise the temperature of the mixed solution to 25°C, stir and keep it warm for 3 hours; then raise the temperature of the mixed solution to 35°C, and continue stirring And keep it warm for...

Embodiment 2

[0044] Step 1, 1mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 9 mL of 1mol / L dilute HNO 3 , stirred for 30 minutes, then added 3 mL of oleic acid, 3 mL of n-heptane and 10 mL of acetone dropwise at a rate of 2 drops / second, stirred for 10 minutes, and then added 5 mL of 10 mol / L NaOH solution at a rate of 2 drops / second to form Precursor solution, stirring the precursor solution at room temperature for 8.5h, prepared Bi 2 o 3 Precipitate, wash and dry the precipitate for later use;

[0045] Step 2, 115mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in turn, stir at 0°C to obtain a mixed solution; then raise the temperature of the mixed solution to 25°C, stir and keep it warm for 3 hours; then raise the temperature of the mixed solution to 35°C, and continue stirring And keep it warm for o...

Embodiment 3

[0053] Step 1, 1mmoL Bi(NO 3 ) 3 ·5H 2 O dissolved in 9 mL of 1mol / L dilute HNO 3 , stirred for 30 minutes, then added 3 mL of oleic acid, 3 mL of n-heptane and 10 mL of acetone dropwise at a rate of 2 drops / second, stirred for 10 minutes, and then added 5 mL of 10 mol / L NaOH solution at a rate of 2 drops / second to form a precursor solution, the precursor solution was stirred at room temperature for 7.5h to prepare Bi 2 o 3 Precipitate, wash and dry the precipitate for later use;

[0054] Step 2, 115mL of concentrated H 2 SO 4 Put it in a conical flask, place the conical flask in a low-temperature thermostat, cool down to 0°C and keep the temperature for 35min; Add 5g of graphite, 5g of sodium nitrate and 15g of potassium permanganate in turn, stir at 0°C to obtain a mixed solution; then raise the temperature of the mixed solution to 25°C, stir and keep it warm for 3 hours; then raise the temperature of the mixed solution to 35°C, and continue stirring And keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com