Substrateless magnetic glittering pigment and preparation method and application thereof

A flashing pigment, no substrate technology, applied in the direction of inorganic material magnetism, magnetic materials, inorganic pigment treatment, etc., can solve the problems that cannot meet the requirements of decorative applications, achieve a significant color-dependent effect, economical and reliable, and a wide range of applications wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

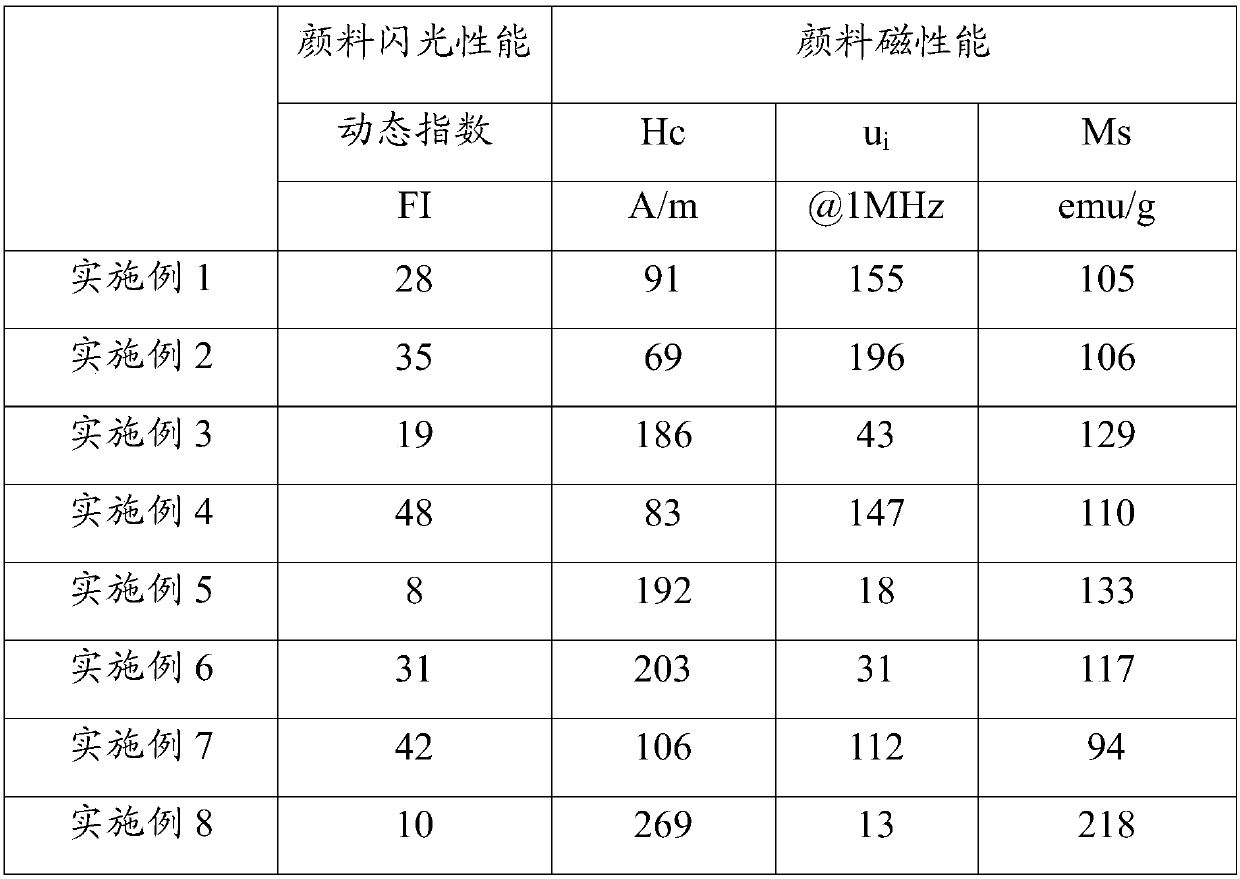

Embodiment 1

[0064] Prepare the following materials in parts by weight: 100 parts of sendust powder with an average particle size of 60 μm obtained by mechanical crushing (in this sendust powder, the mass fraction of silicon is 9.7%, and the mass fraction of aluminum is 5.8%, the mass fraction of iron is 84.5%), 120 parts of solvent ethanol, 0.2 part of ball milling aid stearic acid, 1500 parts of diameters are 5mm stainless steel balls. Put the prepared material into a sand mill and grind for 10 hours to obtain the primary powder; then dry the primary powder in a vacuum oven and heat-treat it at 750°C for 2 hours under an argon atmosphere to obtain the secondary powder; then the secondary powder Through a 100-mesh sieve, the average particle size is 51um, and the bulk density is 0.51g / cm 3 , a finished baseless magnetic glitter pigment with an aspect ratio of 32. Mix 10g of the above-mentioned substrateless magnetic glitter pigment with 90g of standard NC-acrylate paint, apply the result...

Embodiment 2

[0066] Prepare the following materials in parts by weight: 100 parts of sendust powder with an average particle size of 60 μm obtained by mechanical crushing (in this sendust powder, the mass fraction of silicon is 9.7%, and the mass fraction of aluminum is 5.8%, the mass fraction of iron is 84.5%), 250 parts of solvent ethanol, 0.3 part of ball milling aid stearic acid, 2500 parts of diameters are 5mm hard chrome balls. Put the prepared material into a sand mill and grind for 10 hours to obtain the primary powder; then dry the primary powder in a vacuum oven and heat-treat it at 780°C for 2 hours under an argon atmosphere to obtain the secondary powder; then the secondary powder Through a 100-mesh sieve, the average particle size is 68um, and the bulk density is 0.38g / cm 3 , The finished baseless magnetic glitter pigment with an aspect ratio of 42.

Embodiment 3

[0068] Prepare the following materials in parts by weight: 100 parts of FeSiCr alloy powders with an average particle size of 12um (in this FeSiCr alloy powders, the massfraction of silicon is 12%, and the massfraction of chromium is 1.8%, the mass fraction of iron is 86.2%), 120 parts of solvent D-80 mineral spirits, 0.2 part of ball milling aid stearic acid, 1500 parts of diameters are 3mm stainless steel balls. Put the prepared material into a planetary ball mill and grind for 5 hours to obtain the primary powder; then dry the primary powder in a vacuum oven and heat-treat it at 450°C for 2 hours under an argon atmosphere to obtain the secondary powder; then pass the secondary powder through The 100 mesh sieve obtained an average particle size of 35um and a bulk density of 0.46g / cm 3 , The finished baseless magnetic glitter pigment with an aspect ratio of 22.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com