Tundish composite working lining, making method thereof and tundish

A tundish and working lining technology, applied in the field of iron and steel metallurgy, can solve problems such as low production efficiency, difficult construction, and long baking time of coating materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

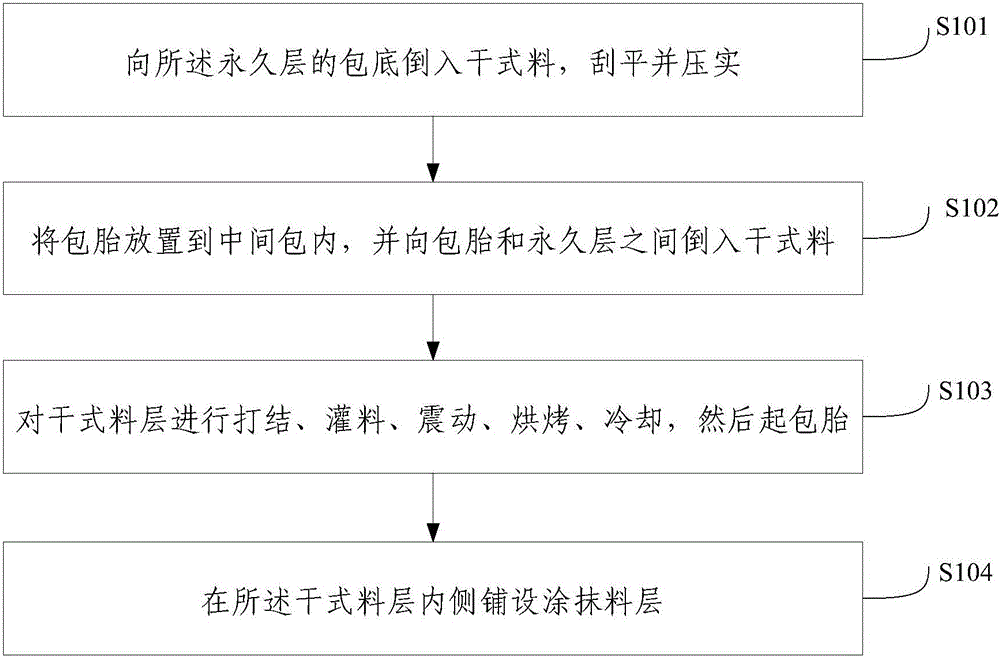

Method used

Image

Examples

Embodiment 1

[0081] The composite working lining of the tundish provided in this embodiment is composed of a dry material layer and a smear layer;

[0082] First, the dry bed consists of the following components:

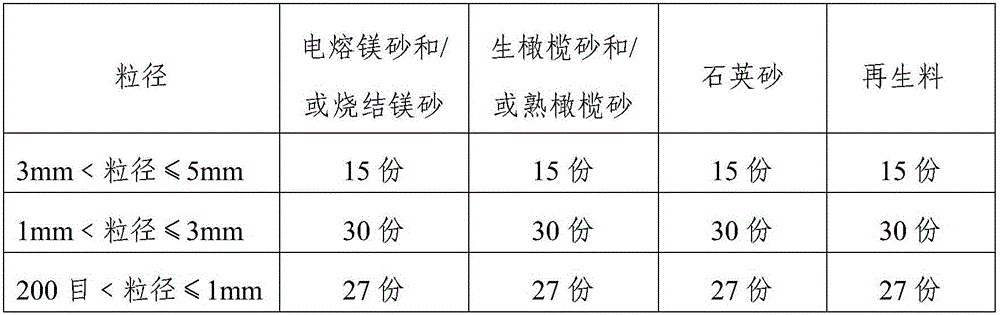

[0083] (1) The aggregate is composed of the following components:

[0084]

[0085] (2) The matrix is composed of the following components:

[0086]

[0087] (3) The binding agent is composed of the following components:

[0088]

[0089] (4) described additive is made up of following composition:

[0090] additive

[0091] Secondly, the smear layer is also composed of aggregate, matrix, binder and additives. In practical applications, the composition of the smear layer can be the same as that of the dry material layer provided by this embodiment. The difference between the two lies in : In the dry material layer, the binder is 5 parts, and the additive is 2 parts, while in the smear layer, the binder is 2.5 parts, and the additive is 5.5 parts, so the dr...

Embodiment 2

[0093] The composite working lining provided in this embodiment is composed of a dry material layer and a smear layer;

[0094] First, the dry bed consists of the following components:

[0095] (1) The aggregate is composed of the following components:

[0096]

[0097] (2) The matrix is composed of the following components:

[0098]

[0099] (3) The binding agent is composed of the following components:

[0100]

[0101] (4) described additive is made up of following composition:

[0102] additive

[0103] Secondly, the smear layer is also composed of aggregate, matrix, binder and additives. In practical applications, the composition of the smear layer can be the same as that of the dry material layer provided by this embodiment. The difference between the two lies in : In the dry material layer, the binder is 4 parts, and the additive is 1.5 parts, while in the spread material layer, the binder is 3 parts, and the additive is 6 parts, so the dry mater...

Embodiment 3

[0105] The composite working lining provided in this embodiment is composed of a dry material layer and a smear layer;

[0106] First, the dry bed consists of the following components:

[0107] (1) The aggregate is composed of the following components:

[0108]

[0109] (2) The matrix is composed of the following components:

[0110]

[0111] (3) The binding agent is composed of the following components:

[0112]

[0113] (4) described additive is made up of following composition:

[0114] additive

clay

Silica powder

glass powder

Antioxidants

number of copies

2

2

1

2

2

1

0.5

[0115] Secondly, the smear layer is also composed of aggregate, matrix, binder and additives. In practical applications, the composition of the smear layer can be the same as that of the dry material layer provided by this embodiment. The difference between the two lies in : In the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com