Method for preparing medical femoral head prosthesis dense alumina ceramic

A technology of alumina ceramics and femoral head, applied in the field of materials, can solve the problems of uneven distribution, abnormal growth, ineffective control of powder particle size, etc., and achieve the effect of good toughness, reliability and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

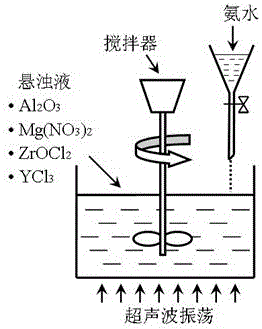

[0032] The preparation process of the medical femoral head prosthesis dense alumina ceramics of the present embodiment is as follows figure 1 Shown:

[0033]1. Prepare the alumina powder with a particle size of 0.2-2.0 microns according to the ratio of adding 15-25 alumina balls with a diameter of 8-12 mm per 100 grams of alumina powder, and then pour it into the ball mill tank High-speed ball milling for 3~5 hours; then pour figure 2 In the funnel of the winnowing device shown. figure 2 The winnowing device shown includes a raw material hopper, tuyere and a collector. The tuyere is set under the mouth of the raw material funnel, and a control valve is installed at the mouth of the raw material funnel and the tuyere. Place a collector, where the collector is wide-mouthed. Adjust the wind speed at the tuyere of the tuyere to 1.1m / s, adjust the flow rate of the alumina powder in the funnel to 0.1L / min, adjust the height between the tuyere and the collector to 0.3m, and adjus...

Embodiment 2

[0039] The preparation process of the medical femoral head prosthesis dense alumina ceramics of the present embodiment is as follows figure 1 Shown:

[0040] 1. Prepare the alumina powder with a particle size of 0.2-2.0 microns according to the ratio of adding 15-25 alumina balls with a diameter of 8-12 mm per 100 grams of alumina powder, and then pour it into the ball mill tank High-speed ball milling for 3~5 hours; then pour figure 2 In the funnel of the winnowing device shown. figure 2 The winnowing device shown includes a raw material hopper, tuyere and a collector. The tuyere is set under the mouth of the raw material funnel, and a control valve is installed at the mouth of the raw material funnel and the tuyere. Place a collector, where the collector is wide-mouthed. Adjust the wind speed at the tuyere of the tuyere to 1.0m / s, adjust the flow rate of the alumina powder in the funnel to 0.12L / min, adjust the height between the tuyere and the collector to 0.28m, and ad...

Embodiment 3

[0046] The preparation process of the medical femoral head prosthesis dense alumina ceramics of the present embodiment is as follows figure 1 Shown:

[0047] 1. Prepare the alumina powder with a particle size of 0.2-2.0 microns according to the ratio of adding 15-25 alumina balls with a diameter of 8-12 mm per 100 grams of alumina powder, and then pour it into the ball mill tank High-speed ball milling for 3~5 hours; then pour figure 2 In the funnel of the winnowing device shown. figure 2 The winnowing device shown includes a raw material hopper, tuyere and a collector. The tuyere is set under the mouth of the raw material funnel, and a control valve is installed at the mouth of the raw material funnel and the tuyere. Place a collector, where the collector is wide-mouthed. Adjust the wind speed at the tuyere of the tuyere to 1.1m / s, adjust the flow rate of alumina powder in the funnel to 0.11L / min, adjust the height between the tuyere and the collector to 0.32m, and adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com