Medical stone ware preparing method and ware prepared by method

A technology of medical stone and utensils, which is applied in the field of preparation of medical stone utensils, can solve the problems of underutilization of mineral elements and waste of raw medical stone raw materials, and achieve high utilization efficiency, high molding rate, and health care performance Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

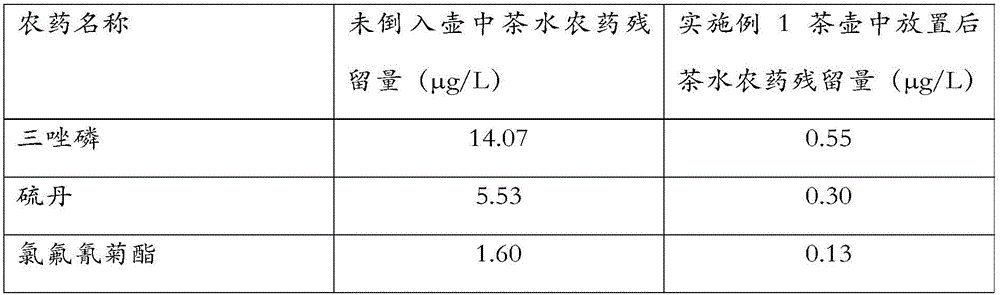

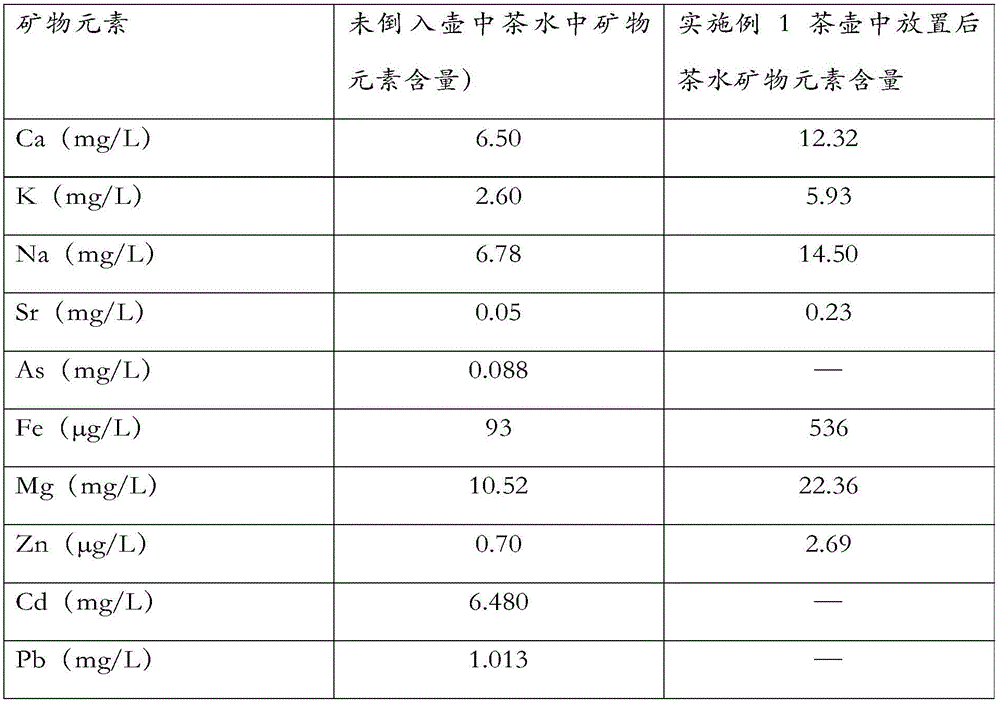

Embodiment 1

[0051] (1) Mineral dressing: Select the deep-layer medical stone ore in the Songshan area, and place it in the natural environment of wind and sun for more than 2 years, so that it can effectively decompose and release minerals, and then wash the ore with water, sieve, and remove small particles. Granular impurities are raw medical stone ore. Then, the medical stone raw ore is cleaned and sieved to dry for later use.

[0052] (2) Proportion mixing: According to the mass percentage of 70% medical stone raw ore, 15% kaolin, 5% negative ion powder and 10% inorganic salt compound mixture of magnesium, copper, zinc, rare earth, potassium and nickel, weigh an appropriate amount respectively The raw materials are then mixed in a closed environment and ground into a powder in a grinder. During the grinding process, a magnet is set above the grinder to remove excess iron impurities in the process of being processed into powder; at the same time, a small blower is set next to the grind...

Embodiment 2

[0069] Mineral dressing, cleaning and sieving according to the method described in Example 1, and according to the mass percentage 50% medical stone ore, 20% kaolin, 10% negative ion powder and 20% inorganic salt compounds of magnesium, copper, zinc, rare earth, potassium, nickel Mixture, weigh appropriate amount of each raw material. Then, according to the method described in Example 1, carry out proportioning, mixing, milling and mud refining, and take out the mud-like raw material from the film after sealing, and beat it into thin and uniform mud flakes on a flat platform; then, put the mud flakes Cut it into the width required to make a barrel-shaped vessel, and combine mud pieces of moderate width into a bucket shape, then use a brush to dip in water to organically bond the joints of the mud pieces, and carry out shaping and bonding according to the method described in Example 1. Firing, and polishing the barrel-shaped vessel after firing with coconut shell and 320 yards ...

Embodiment 3

[0071] Mineral dressing, cleaning and sieving according to the method described in Example 1, and according to the mass percentage 85% medical stone raw ore, 10% kaolin, 3% negative ion powder and 2% inorganic salt compounds of magnesium, copper, zinc, rare earth, potassium, nickel Mixture, weigh appropriate amount of each raw material. Then, according to the method described in Example 1, carry out proportioning, mixing, milling and mud refining, and take out the mud-like raw material from the film after sealing, and beat it into thin and uniform mud flakes on a flat platform; then, put the mud flakes Cut it into the width required for making a bottle-shaped vessel, and combine the moderately wide mud pieces into the form of a bottle, then use a brush to dip in water to organically bond the joints of the mud pieces, and carry out shaping and processing according to the method described in Example 1. Firing, and polishing the bottle-shaped vessel after firing with coconut shel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com