Acid-resistant dry-mixed mortar

A dry powder mortar, acid resistance technology, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of insufficient material source and poor acid resistance, and achieve the effect of reducing production cost and enhancing acid resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] An acid-resistant dry powder mortar, including the following components, and the mass percentage of each component is: combined cement 25%, foundry waste 10%, yellow sand 34%, fly ash 3%, slag powder 12%, lithium slag 15%, 0.6% wood fiber, 0.3% cellulose ether, 0.03% redispersible polymer, 0.07% polysiloxane powder;

[0014] Wherein, the combined cement is a combination of crystalline cement, high-resistance sulfuric acid Portland cement and fast hardening sulphoaluminate cement, and the combination ratio is 1:1.2:2.

Embodiment 2

[0016] An acid-resistant dry powder mortar, including the following components, and the mass percentage of each component is: combined cement 28%, foundry waste sand 6%, yellow sand 36%, fly ash 5%, slag powder 10%, lithium slag 12%, 0.7% wood fiber, 0.2% cellulose ether, 0.04% redispersible polymer, 0.06% polysiloxane powder;

[0017] Wherein, the combined cement is a combination of crystallized cement, high-resistant sulfuric acid Portland cement and fast hardening sulphoaluminate cement, and the combination ratio is 1:1.3:1.9.

Embodiment 3

[0019] An acid-resistant dry powder mortar, including the following components, and the mass percentage of each component is: combined cement 30%, foundry waste sand 5%, yellow sand 38%, fly ash 2%, slag powder 14%, lithium slag 10%, 0.7% wood fiber, 0.2% cellulose ether, 0.02% redispersible polymer, 0.08% polysiloxane powder;

[0020] Wherein, the combined cement is a combination of crystalline cement, high-resistant sulfuric acid Portland cement and fast hardening sulphoaluminate cement, and the combination ratio is 1:1.5:1.8.

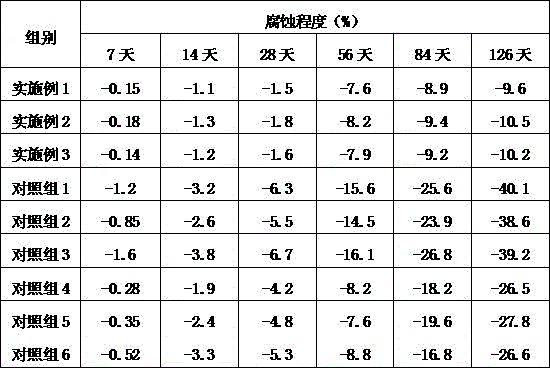

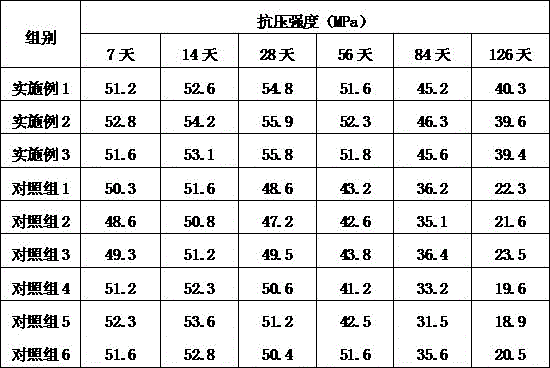

[0021] Replace 25% of the combined cement with a single type of sand, which is the control group 1-3, and replace it with two types of sand, which are 4-6 respectively. The specific correspondence is as follows:

[0022] Group cement Ratio Control group 1 Crystallized cement / Control group 2 High resistance to sulfuric acid Portland cement / Control group 3 Fast hardening sulphoaluminate cement / Control group 4 Crystallized cement and high resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com