Antifouling dry-powdered emulsion paint and preparation method thereof

A technology of dry powder latex and latex paint, applied in the field of paint, can solve the problems of inconvenient packaging, transportation and storage, waste of resources, poor coating hardness and other problems of liquid latex paint, and achieve increased consistency and water retention performance, convenient storage and transportation, and improved The effect of microporous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

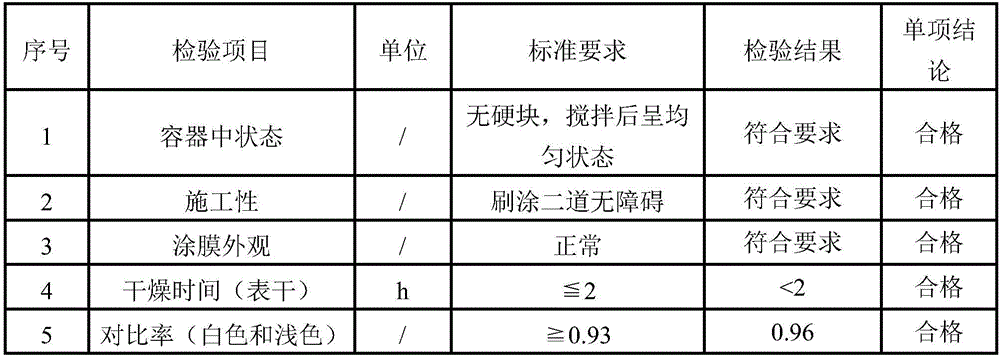

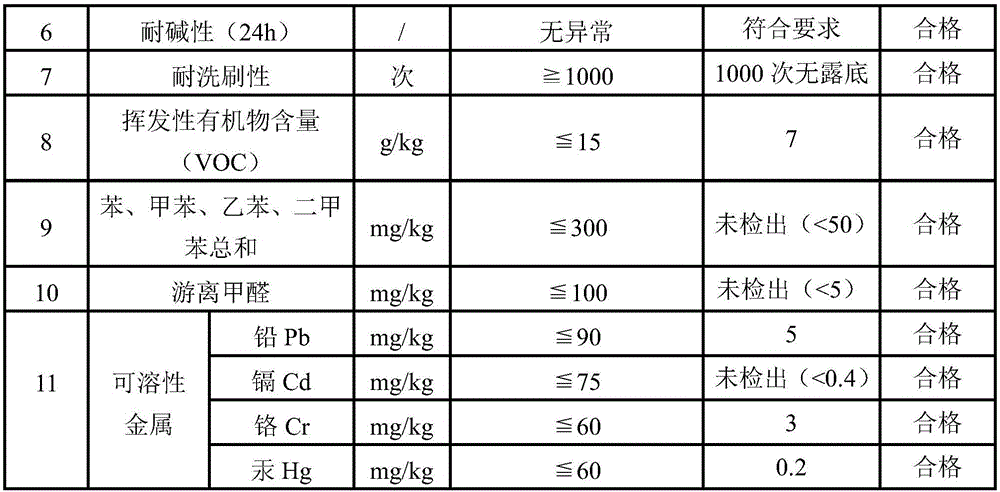

Examples

Embodiment 1

[0053] The present embodiment provides a kind of antifouling dry powder latex paint, and raw material component comprises:

[0054] Particle size is 300 mesh white cement, 15 parts by weight;

[0055] Light calcium carbonate with a particle size of 600 meshes, 8 parts by weight;

[0056] Granularity 600 mesh heavy calcium carbonate, 6 parts by weight;

[0057] Granularity is 400 mesh ash calcium, 35 parts by weight;

[0058] Talcum powder, 10 parts by weight;

[0059] Kaolin, 8 parts by weight;

[0060] Titanium dioxide, 8 parts by weight;

[0061] Hydroxyethyl cellulose ether, 0.4 parts by weight;

[0062] VAE redispersible latex powder (Shanxi Sanwei Group, SWF-04 type), 10 parts by weight;

[0063] Polycarboxylate superplasticizer (Swiss Sika Viscocrete 325C), 0.3 parts by weight;

[0064] Sodium gluconate, 0.05 parts by weight;

[0065] Sodium stearate, 0.5 parts by weight;

[0066] Nano silicon dioxide, 1.5 parts by weight;

[0067] PAC, 1.5 parts by weight;

...

Embodiment 2

[0074] The present embodiment provides a kind of antifouling dry powder latex paint, and raw material component comprises:

[0075] Particle size is 1000 mesh white cement, 20 parts by weight;

[0076]Granularity 1200 purpose light calcium carbonate, 10 parts by weight;

[0077] Granularity 1200 purpose heavy calcium carbonate, 8 parts by weight;

[0078] Granularity is 750 mesh ash calcium, 15 parts by weight;

[0079] Talcum powder, 10 parts by weight;

[0080] Kaolin, 8 parts by weight;

[0081] Titanium dioxide, 10 parts by weight;

[0082] Hydroxyethyl cellulose ether, 0.3 parts by weight;

[0083] VAE redispersible latex powder (Shanxi Sanwei Group, SWF-04 type), 12 parts by weight;

[0084] Polycarboxylate superplasticizer (Swiss Sika Viscocrete 325C), 0.5 parts by weight;

[0085] Sodium gluconate, 0.15 parts by weight;

[0086] Sodium stearate, 1 part by weight;

[0087] Nano silica, 2 parts by weight;

[0088] PAC (Zhengzhou Runquan Chemical Products Co., L...

Embodiment 3

[0097] The present embodiment provides a kind of antifouling dry powder latex paint, and raw material component comprises:

[0098] Particle size is 600 mesh white cement, 20 parts by weight;

[0099] Light calcium carbonate with a particle size of 800 meshes, 8 parts by weight;

[0100] 800 meshes of heavy calcium carbonate, 10 parts by weight;

[0101] Granularity is 550 mesh ash calcium, 25 parts by weight;

[0102] Talcum powder, 12 parts by weight;

[0103] Kaolin, 10 parts by weight;

[0104] Titanium dioxide, 14 parts by weight;

[0105] Hydroxyethyl cellulose ether, 0.6 parts by weight;

[0106] VAE redispersible latex powder, 8 parts by weight;

[0107] Polycarboxylate water reducer, 0.4 parts by weight;

[0108] Sodium gluconate, 0.1 parts by weight;

[0109] Sodium stearate, 0.7 parts by weight;

[0110] Nano silica, 2.5 parts by weight;

[0111] PAC, 2.5 parts by weight;

[0112] Organosilicon water repellent, 0.2 parts by weight;

[0113] Thickener, 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com