Municipal excess sludge biologic drying organic conditioning agent and preparation method thereof

A technology of excess sludge and biological drying, applied in the field of environmental engineering, can solve the problems of large amount of use, low efficiency of biological drying, low utilization efficiency of auxiliary materials, etc., achieve high acid production, realize resource utilization, and increase adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

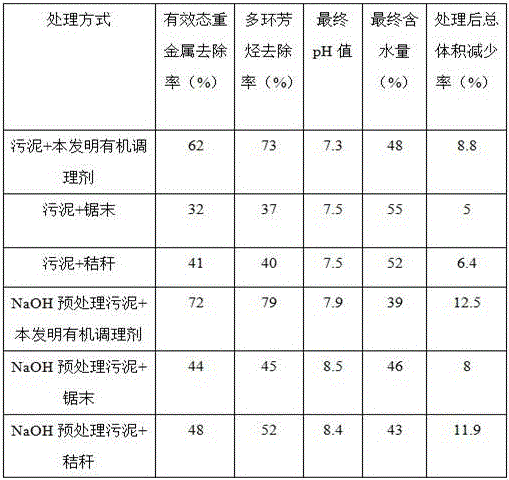

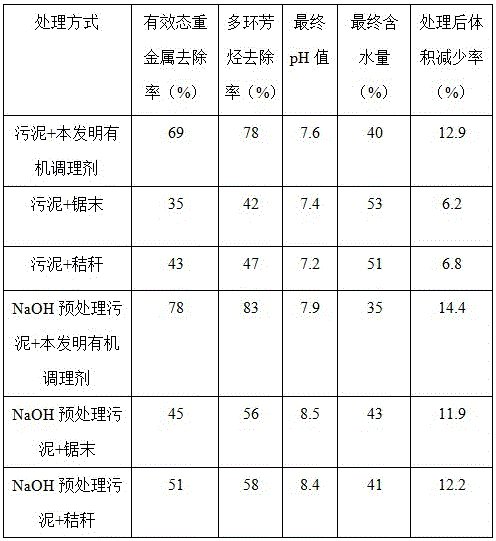

Embodiment 1

[0022]Embodiment 1: a kind of preparation method of municipal residual sludge biological drying organic conditioner, it comprises the following steps: (1) preparation of conditioner matrix: the cellulase fermented waste bacteria residue and furfural residue after drying are according to Mix well at a ratio of 0.5:1 by weight, pass through a 10-mesh sieve after crushing, and then put it into the atmosphere furnace. After vacuuming the atmosphere furnace, nitrogen gas is introduced to start low-temperature baking; set the atmosphere furnace at a rate of 10°C / min. The temperature was raised from room temperature to 450°C; maintained at 450°C for 120 minutes; the heating was stopped, and the temperature was naturally lowered to room temperature to obtain the conditioning agent matrix. (2) Preparation of bioaugmentation conditioner matrix: add 0.1 g of Trichoderma aculeatus CGM-10 spore powder with the preservation number CCTCCNo. M 2014001 to 1000 g of the conditioner matrix obtain...

Embodiment 2

[0030] Embodiment 2: the preparation method of municipal residual sludge biological drying organic conditioner, it comprises the following steps: (1) preparation of conditioner matrix: the cellulase fermented waste bacteria residue and furfural residue after drying are divided into parts by weight Mix well at a ratio of 0.8:1, pass through a 10-mesh sieve after being crushed, and then put it into the atmosphere furnace, vacuum the atmosphere furnace and feed nitrogen to start low-temperature baking; set the atmosphere furnace to heat up from room temperature at a rate of 10°C / min to 450° C.; keep for 120 minutes; stop heating, and naturally cool down to room temperature to obtain a conditioner matrix. (2) Preparation of bioaugmentation conditioner matrix: Add 0.5 g of Trichoderma aculeatus CGM-10 spore powder with preservation number CCTCC No. M2014001 to 1000 g of conditioner matrix obtained in step (1), and mix to obtain bioaugmentation The conditioner matrix acts as a micro...

Embodiment 3

[0037] Embodiment 3: municipal residual sludge biological drying organic conditioner and preparation method thereof, it comprises the following steps: (1) preparation of conditioner matrix: the cellulase fermentation waste bacteria residue and furfural residue after drying are weighed The ratio of 1:1 is fully mixed, after being crushed, it is passed through a 10-mesh sieve, and then put into the atmosphere furnace. After vacuuming the atmosphere furnace, nitrogen gas is introduced to start low-temperature baking; the atmosphere furnace is set at a rate of 10°C / min. Raise the temperature to 450° C.; maintain it for 60 minutes; stop heating, and naturally cool down to room temperature to obtain the conditioning agent matrix. (2) Preparation of bioaugmented conditioner matrix: add 1 g of Trichoderma aculeatus CGM-10 spore powder with preservation number CCTCC No. M2014001 to 1000 grams of carbonized material obtained in step (1), and mix to obtain bioaugmented conditioner agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com