A cooling treatment system for iron oxide powder in acid regeneration station

A technology of iron oxide powder and treatment system, which is applied in the direction of iron oxide, iron oxide/iron hydroxide, inorganic chemistry, etc., can solve the problems of short service life of dust separation equipment, increase of production cost, small air intake, etc., and achieve improvement Effect of cooling effect, prolonging service life, and reducing equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

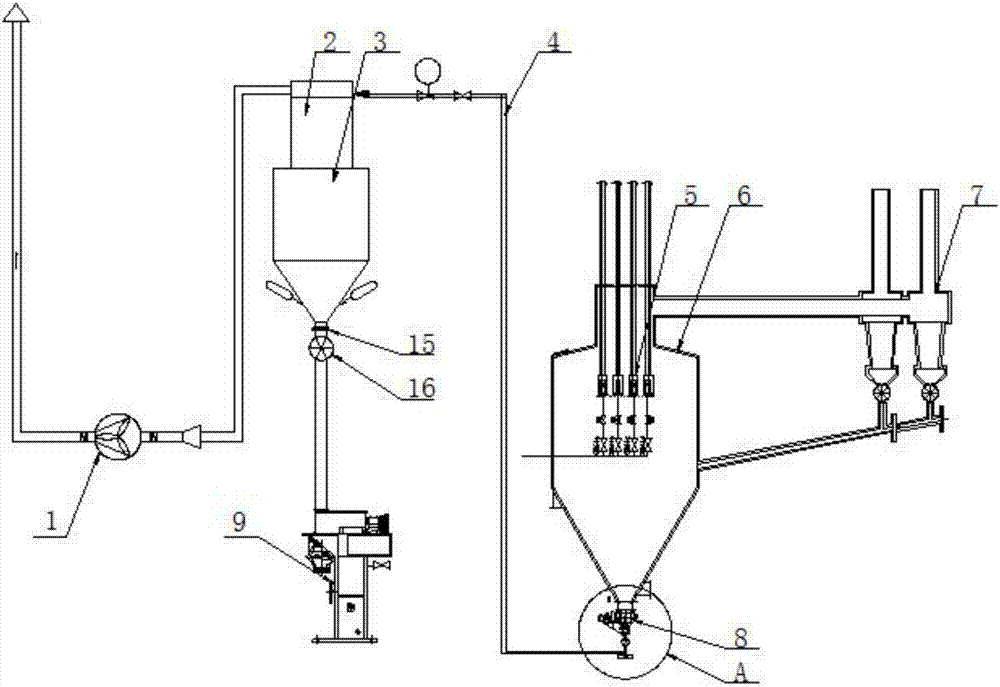

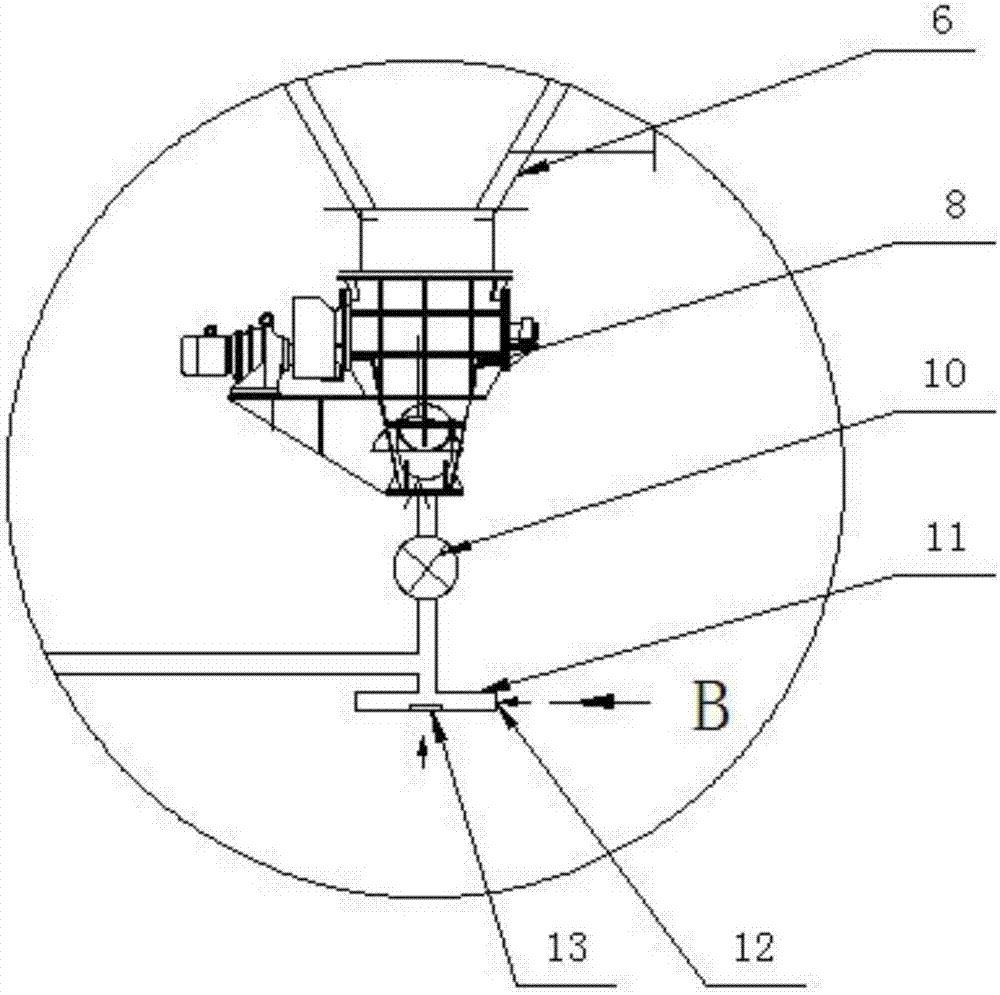

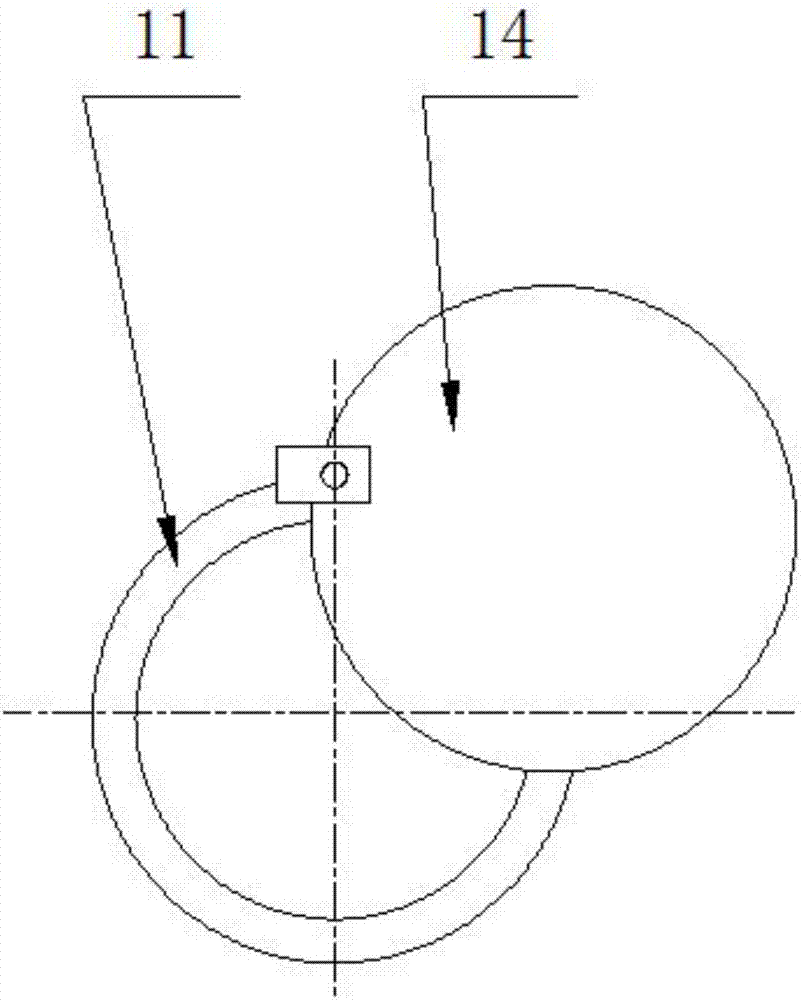

[0019] A cooling and cooling treatment system for iron oxide powder in an acid regeneration station, including a roasting furnace 6, an agglomerate crusher 8, a roasting furnace rotary valve 10, an iron oxide powder conveying pipeline 4, an iron oxide powder bin 3, and a plastic burner plate dust separator 2 , Iron powder bin plug-in valve 15, iron powder bin rotary valve 16, iron powder bagging machine 9, conveying fan 1. A group of spray guns 5 are installed in the roasting furnace for atomizing waste acid liquid, burners are installed in the roasting furnace for igniting gas, and the gas outlet of the roasting furnace is connected with a double cyclone separator 7. The discharge port at the bottom of the roasting furnace is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com