Instant thickening agent for providing comfortable viscosity and preparation method thereof

An instant-type, high-viscosity technology, applied in the field of thickeners, can solve problems such as uneven product particle size, difficulty in ensuring product uniformity, and difficulty in ensuring product instant solubility, so as to avoid poor color and improve product quality. The effect of overall economic benefit and simple and easy-to-operate preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

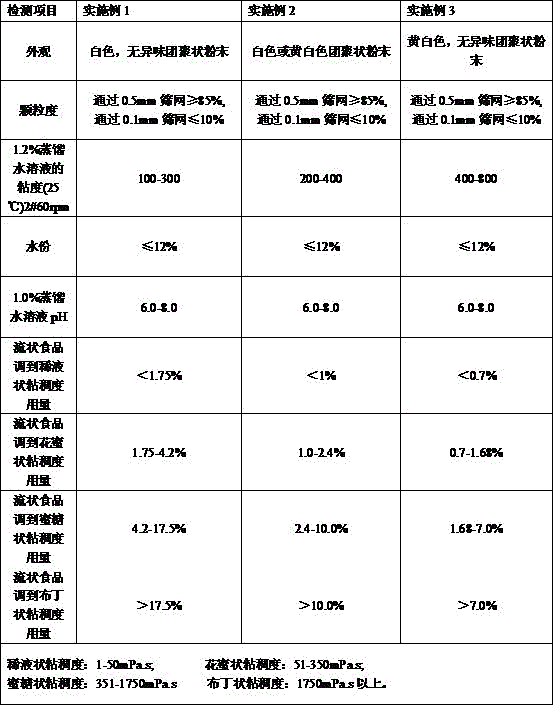

example 1

[0042] Instant thickeners of the present invention that provide a comfortable consistency include

[0043] Xanthan Gum: 20.00%

[0044] Maltodextrin: 80.00%

[0045] Pure water: 1.0-5.0%

[0046] Start the fluidized bed power supply and adjust the gas source pressure to 0.6-0.7Mpa.

[0047] Turn on the jacking switch to seal the host.

[0048] Adjust the damper to the 2 / 3 position.

[0049] Set the automatic / manual switch on the control panel to manual, and close the left and right dampers.

[0050] Start the fan, and after the current of the fan is balanced, open the left and right air doors, and set the automatic / manual switch to automatic.

[0051] Adjust the inlet air temperature (set according to the material process).

[0052] Adjust the air volume, observe the fluidization of the material to the position of the middle cylinder stereoscopic mirror, and then lock the handle.

[0053] After the material temperature rises and is mixed for 10 minutes, adjust the atomi...

example 2

[0066] Instant thickeners of the present invention that provide a comfortable consistency include

[0067] Xanthan Gum: 35.00%

[0068] Maltodextrin: 65.00%

[0069] Pure water: 1.0-5.0%

[0070] Start the fluidized bed power supply and adjust the gas source pressure to 0.6-0.7Mpa.

[0071] Turn on the jacking switch to seal the host.

[0072] Adjust the damper to the 2 / 3 position.

[0073] Set the automatic / manual switch on the control panel to manual, and close the left and right dampers.

[0074] Start the fan, and after the current of the fan is balanced, open the left and right air doors, and set the automatic / manual switch to automatic.

[0075] Adjust the inlet air temperature (set according to the material process).

[0076] Adjust the air volume, observe the fluidization of the material to the position of the middle cylinder stereoscopic mirror, and then lock the handle.

[0077] After the material temperature rises and is mixed for 10 minutes, adjust the atomi...

example 3

[0090] Instant thickeners of the present invention that provide a comfortable consistency include

[0091] Xanthan Gum: 50.00%

[0092] Maltodextrin: 50.00%

[0093] Pure water: 1.0-5.0%.

[0094] Start the fluidized bed power supply and adjust the gas source pressure to 0.6-0.7Mpa.

[0095] Turn on the jacking switch to seal the host.

[0096] Adjust the damper to the 2 / 3 position.

[0097] Set the automatic / manual switch on the control panel to manual, and close the left and right dampers.

[0098] Start the fan, and after the current of the fan is balanced, open the left and right air doors, and set the automatic / manual switch to automatic.

[0099] Adjust the inlet air temperature (set according to the material process).

[0100] Adjust the air volume, observe the fluidization of the material to the position of the middle cylinder stereoscopic mirror, and then lock the handle.

[0101] After the material temperature rises and is mixed for 10 minutes, adjust the atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com