Multilayer film, polarization plate, and multilayer film production method

A manufacturing method and multi-layer film technology, applied in polarizing elements, chemical instruments and methods, coatings, etc., can solve problems such as difficulty in resistance to cohesion and damage, adhesion (adhesive strength may not be sufficient, etc.), and achieve full adhesion. The effect of sex, effective manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0230] (1-1. Manufacture of film formed from layer A)

[0231] Pellets of a resin containing a norbornene-based polymer (glass transition temperature: 137° C.; “ZEONOR 1420R” manufactured by ZEON CO., LTD.) were dried at 100° C. for 5 hours. Then, pellets of the dried resin were fed to a single screw extruder. After the resin is melted in the extruder, it is extruded in sheet form from a T die onto a casting drum through a polymer conduit and a polymer filter, and cooled. Thus, a film having a thickness of 50 μm and a width of 675 mm was obtained.

[0232] (1-2. Preparation of water-based resin composition 1)

[0233] As an aqueous dispersion of polyurethane (a polymer having a polar group as a functional group (polymer Y1)), Superflex (glass transition temperature-35°C; manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd., carbonate-based polyurethane), 100 parts of polyurethane were included, and 20 parts of Denacol EX-521 (manufactured by Nagase ChemteX Co., Ltd.) as a...

Embodiment 2

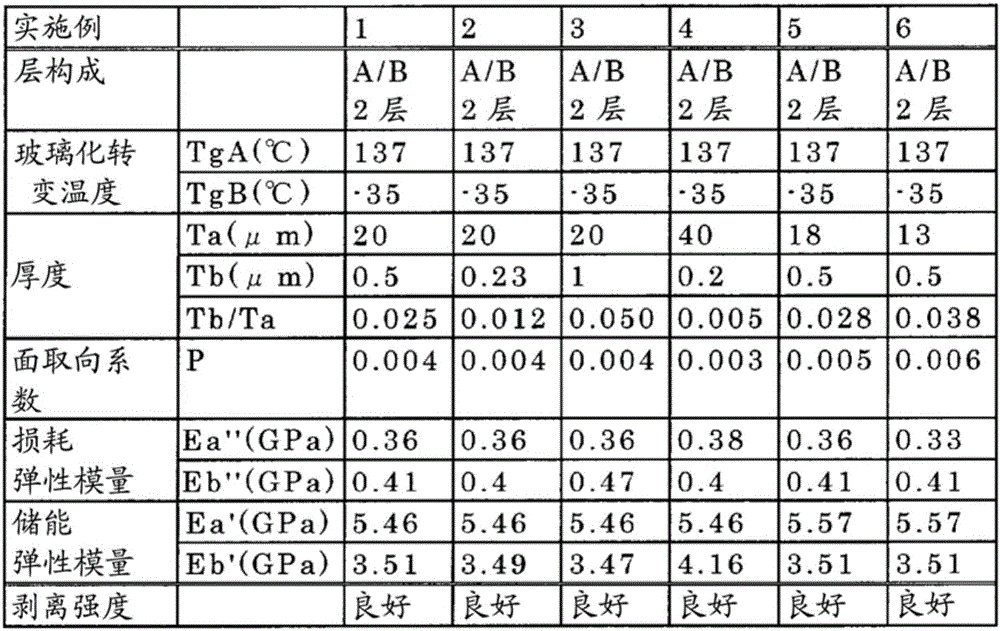

[0238] In the process (1-3) of Example 1, the coating thickness of the liquid aqueous resin composition 1 in the process (1-2) was changed so that the dry film thickness might be 0.6 micrometers. Except for the above, it carried out like Example 1. Thus, the thickness of layer A is 20 μm, the thickness of layer B is 0.23 μm, the orientation coefficient of layer A is 0.004, the loss elastic modulus of layer A is 0.36 GPa, the loss elastic modulus of layer B is 0.4 GPa, the storage elastic modulus of layer A is 5.46 GPa, Multilayer film 2 with a storage elastic modulus of 3.49GPa in layer B. Moreover, the peel strength measurement result was 0.5 N or more, and it was favorable.

Embodiment 3

[0240] In the process (1-3) of Example 1, the coating thickness of the liquid aqueous resin composition 1 in the process (1-2) was changed so that the dry film thickness might be 2.5 micrometers. Except for the above, it carried out like Example 1. Thus, the thickness of layer A is 20 μm, the thickness of layer B is 1 μm, the orientation coefficient of layer A is 0.004, the loss elastic modulus of layer A is 0.36 GPa, the loss elastic modulus of layer B is 0.47 GPa, the storage elastic modulus of layer A is 5.46 GPa, and the elastic modulus of B layer is 5.46 GPa. A multilayer film 3 with a storage elastic modulus of 3.47 GPa. Moreover, the peel strength measurement result was 0.5 N or more, and it was favorable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com