Production technology and production equipment of self-supporting metal-protected fire-resistant cables

A metal protection and fire-resistant cable technology, which is applied in the direction of insulated cables, cable/conductor manufacturing, cables, etc., can solve the problems of limited waterproof effect, low cable support strength, poor cable toughness, etc. The effect of large mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

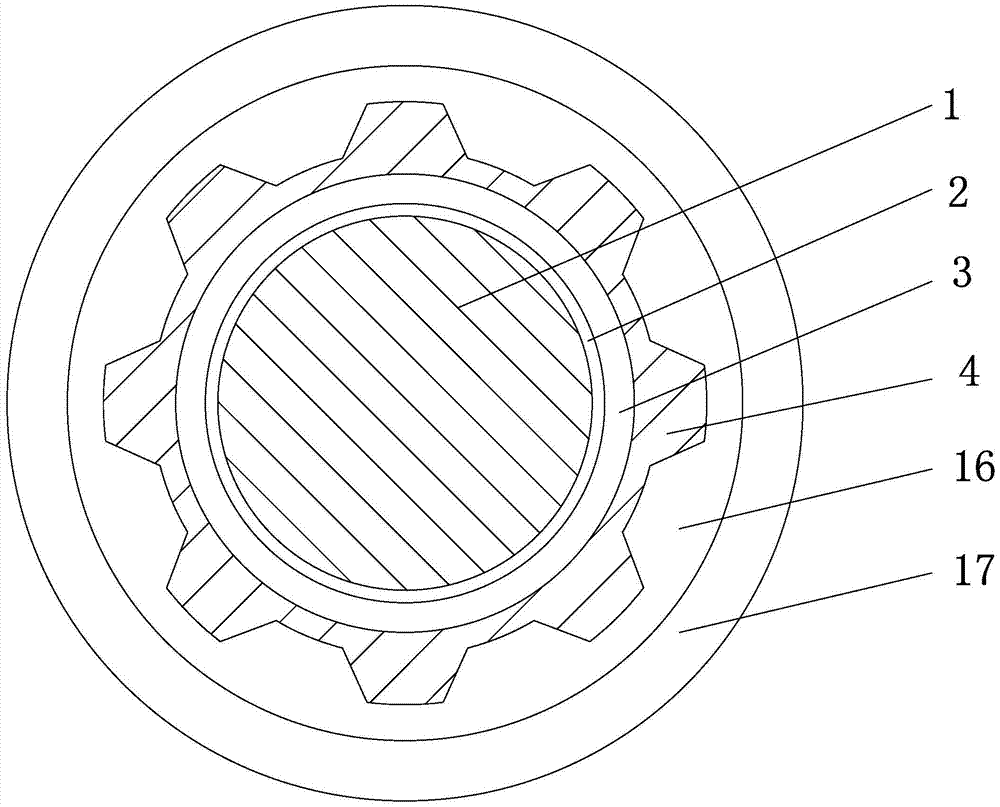

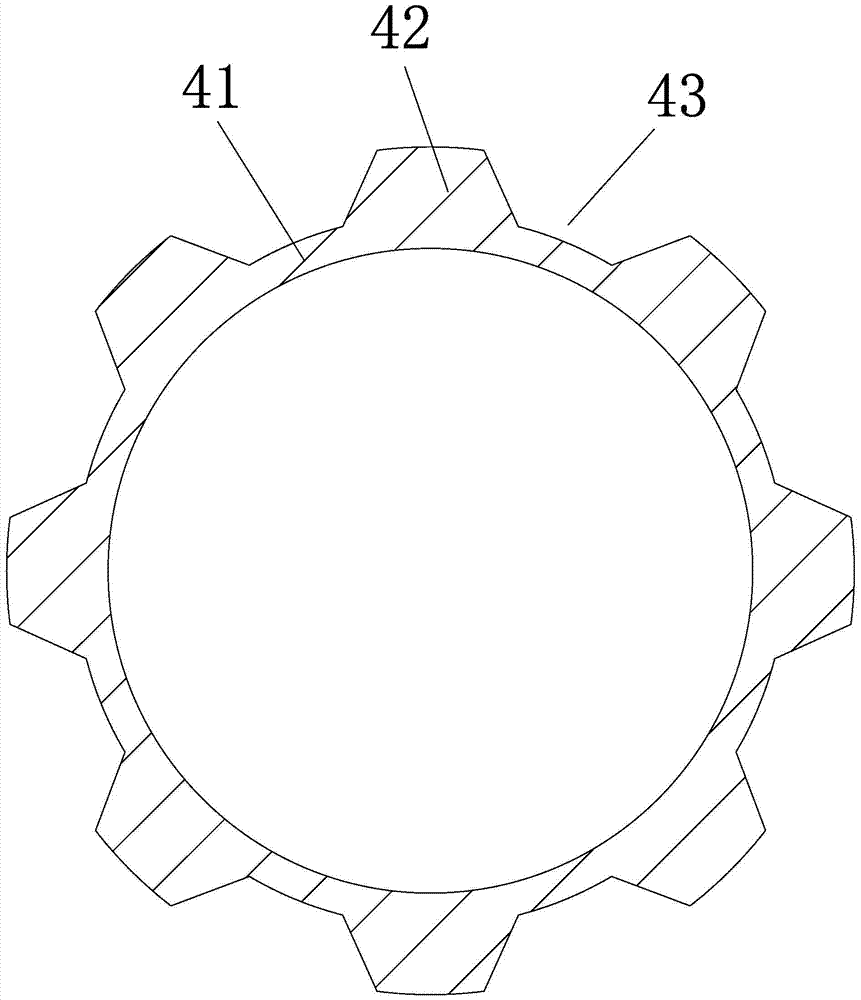

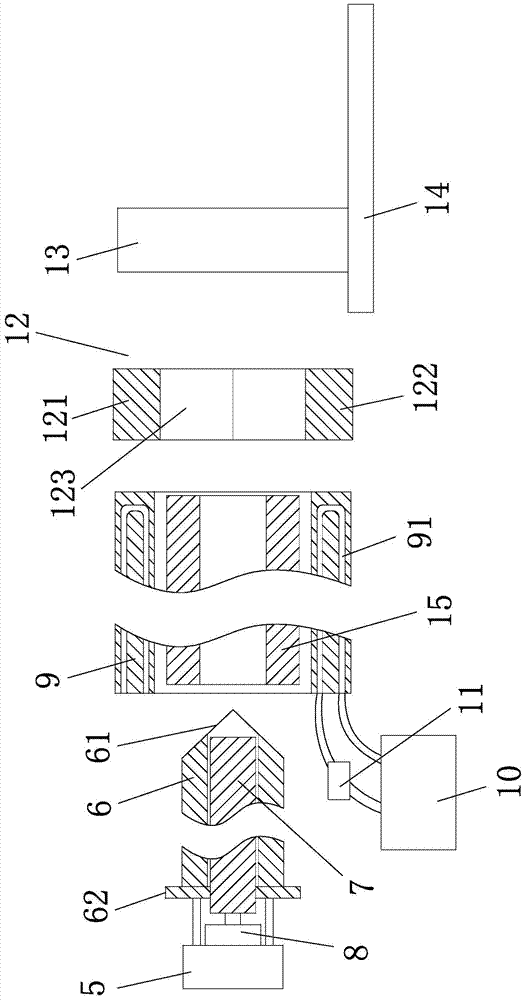

[0022] Embodiment 1: as figure 1 As shown, a self-supporting metal-protected fire-resistant cable includes a copper core conductor 1, a ceramic insulating layer 2 is set on the outside of the copper core conductor, and a fire-resistant mica tape insulating layer 3 is set on the outside of the ceramic insulating layer. The outer side of the insulating layer is provided with a metal sheath 4, such as figure 2 As shown, the metal sheath includes a sleeve 41 and several positioning protrusions 42, the positioning protrusions are evenly distributed around the axis of the sleeve, and the positioning protrusions are in the shape of an isosceles trapezoid and integrally connected with the sleeve. An accommodating groove 43 is provided between two adjacent positioning protrusions, a fireproof mud isolation sleeve 16 is provided on the outer side of the metal sheath, and a flame retardant sheath 17 is provided on the outer side of the fireproof mud isolation sleeve.

[0023] A ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com