A potting process of metallized polypropylene film dielectric capacitor

A polypropylene film and capacitor technology, used in film/thick film capacitors, multilayer capacitors, fixed capacitor components and other directions, can solve the problems of low precision of perfusion volume and low work efficiency, and achieve improved perfusion efficiency and savings. The time of perfusion and the effect of high perfusion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

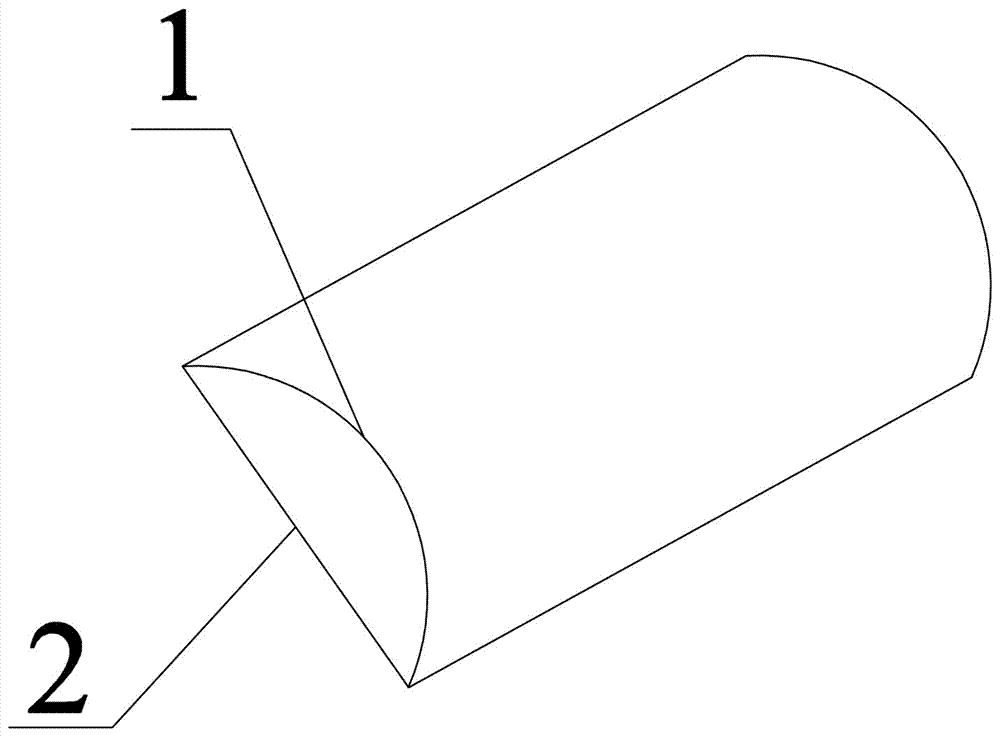

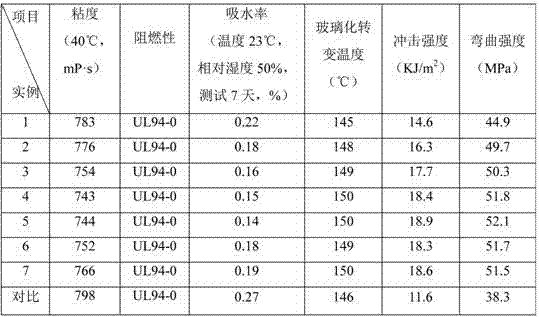

Embodiment 1

[0026] A filling process for a metallized polypropylene film dielectric capacitor, comprising the following steps: the filling head of epoxy resin is close to the inner wall of the capacitor shell, the epoxy resin filling flows from top to bottom along the inner wall of the capacitor shell, and the epoxy resin The liquid level of the filling glue rises gradually, and the position of the perfusion head is also continuously moved up, and finally the perfusion is completed; the perfusion head is a perfusion tube, and the outer wall of the perfusion tube is surrounded by an arc-shaped outer wall 1 and a plane outer wall 2 (see figure 1 ), when the inner wall of the capacitor shell is a curved surface, the arc-shaped outer wall 1 is consistent with the arc of the inner wall of the capacitor shell, so that the outer wall of the perfusion tube and the inner wall of the capacitor shell are bonded; the epoxy resin filling glue includes the following parts by weight Prepared from raw mat...

Embodiment 2

[0031] A filling process for a metallized polypropylene film dielectric capacitor, comprising the following steps: the filling head of epoxy resin is close to the inner wall of the capacitor shell, the epoxy resin filling flows from top to bottom along the inner wall of the capacitor shell, and the epoxy resin The liquid level of the filling glue rises gradually, and the position of the filling head is also continuously moved up, and finally the filling is completed; the filling head is a filling tube, and the outer wall of the filling tube is surrounded by a curved outer wall and a flat outer wall. When the inner wall of the capacitor shell When it is a curved surface, the arc-shaped outer wall is consistent with the arc of the inner wall of the capacitor shell, so that the outer wall of the perfusion tube and the inner wall of the capacitor shell are bonded together; the epoxy resin filling glue is prepared from the following raw materials in parts by weight: double 48 parts ...

Embodiment 3

[0036]A filling process for a metallized polypropylene film dielectric capacitor, comprising the following steps: the filling head of epoxy resin is close to the inner wall of the capacitor shell, the epoxy resin filling flows from top to bottom along the inner wall of the capacitor shell, and the epoxy resin The liquid level of the filling glue rises gradually, and the position of the filling head is also continuously moved up, and finally the filling is completed; the filling head is a filling tube, and the outer wall of the filling tube is surrounded by a curved outer wall and a flat outer wall. When the inner wall of the capacitor shell When it is a plane, the plane outer wall is bonded to the plane inner wall of the capacitor casing; the epoxy resin filling glue is prepared from the following raw materials in parts by weight: 50 parts of bisphenol A epoxy resin E-51, 13 parts of polyester resin, 7 parts of dimethyl methyl phosphate, 36 parts of silicon micropowder, 38 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com