A process for inducing alloy directional solidification growth and strengthening alloy refining process by direct current electric field

A technology of strengthening alloys and directional solidification, which is applied in silicon compounds, inorganic chemistry, manufacturing tools, etc., can solve the problems of lower refining temperature, limited primary crystal phase, and limited effective separation, so as to reduce energy consumption, lower refining temperature, and enhance The effect of the purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

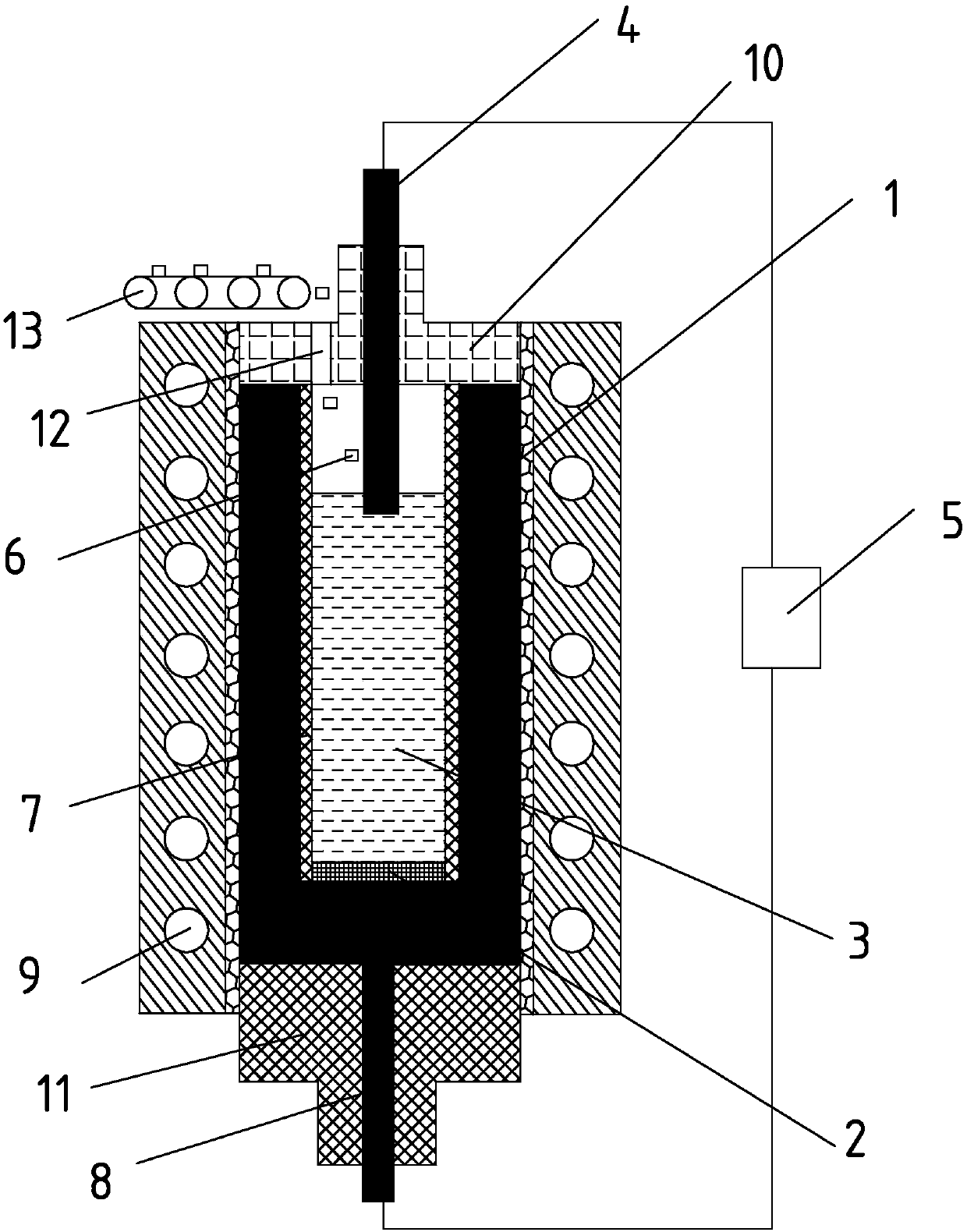

[0022] Such as figure 1 As shown, a DC electric field induces alloy directional solidification growth and strengthens the process of alloy refining, which has the following steps:

[0023] S1. Select one or more of the elements Al, Sn, Fe, Cu and Zn to form an alloy with the element Si;

[0024] S2. According to the alloy phase diagram, select the required alloy ratio, and according to the ratio, prepare and smelt to obtain the Si-M master alloy;

[0025] S3. Select the graphite crucible 1 as the melting crucible, the inner wall of the graphite crucible 1 is insulated, place the broken crystal 2 of high-purity silicon at the bottom of the graphite crucible 1 as the substrate, and then place the Si-M master alloy in the graphite crucible 1;

[0026] S4. Heating the Si-M master alloy to the liquidus temperature to obtain the Si-M alloy melt 3, inserting the graphite electrode I4 into the Si-M alloy melt 3, starting the DC power supply 5, and the graphite electrode I4 and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com