Single-layer multi-material surface overlay system based on powder bed additive manufacturing

A kind of additive manufacturing and multi-material technology, applied in the field of powder bed additive manufacturing, can solve the problems that are difficult to meet the complexity requirements of industrial products, flexibility and high efficiency requirements, and achieve precise control of powder coating amount, fast movement speed, and improved production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

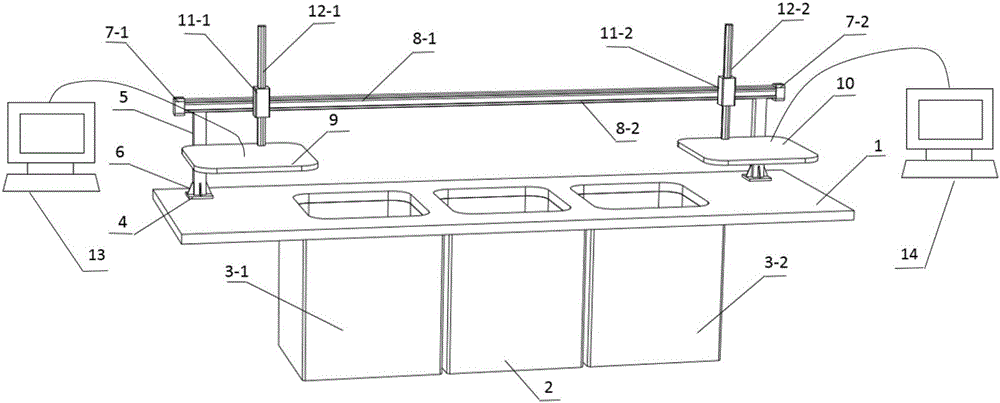

[0024] refer to figure 1 , a single-layer multi-material surface laying system for powder bed additive manufacturing, including a forming worktable 1, a forming cylinder 2 is provided in the middle below the forming worktable 1, and a first powder supply cylinder is provided on both sides of the forming cylinder 2 3-1 and the second powder supply cylinder 3-2, the two sides above the forming table 1 are fixedly connected by the connecting plate 4 and the truss mechanism 5 respectively, and a rib 6 is also connected between the connecting plate 4 and the truss mechanism 5, and the truss The mechanism 5 is equipped with a first slide rail 8-1 and a second slide rail 8-2, the first slide rail 8-1 and the second slide rail 8-2 are arranged in parallel in the vertical direction, and the first slide rail 8-1 Cooperate with the first slider 11-1, the first slider 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com