Motor stator clamping ring

A technology of motor stator and tooth pressure plate, which is applied to the static parts of the magnetic circuit, the shape/style/structure of the magnetic circuit, etc., can solve the problems of winding temperature rise, etc., to reduce end loss, prevent tooth expansion, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

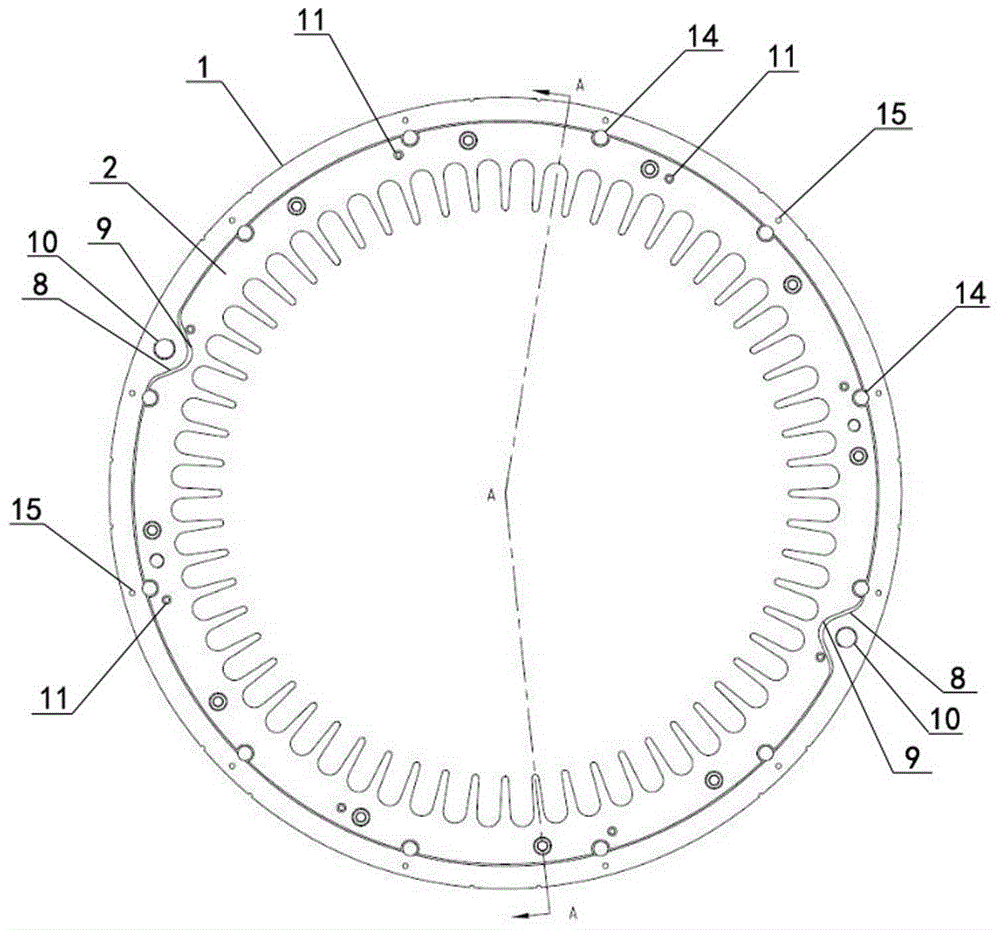

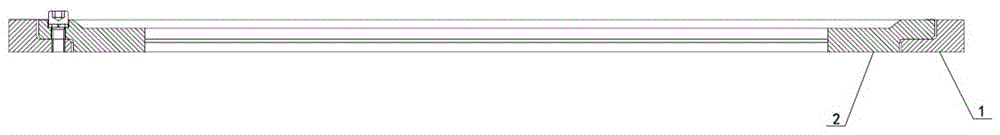

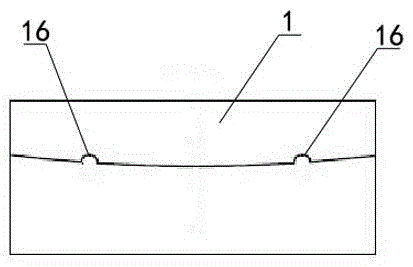

[0015] The motor stator pressure ring includes a ring-shaped steel sleeve 1, a ring-shaped structure and a tooth pressure plate 2 with a number of teeth uniformly distributed radially on the inner circle, and an annular stop 3 is opened at one end of the steel sleeve 1, and the annular stop 3 are provided with a number of threaded holes 4 along the circumference, and the outer circle of the tooth pressure plate 2 is an annular stepped structure. The pressure plate 2 is tightly fitted with the threaded hole 4 on the annular seam 3 through the hexagon socket bolt and washer assembly; the tooth pressure plate 2 is made of non-magnetic silicon-aluminum alloy.

[0016] During specific implementation, the annular stepped structure of the tooth pressure plate 2 is composed of the first annular stepped surface 5, the second annular stepped surface 6 and the third annular stepped surface 7 which are successively connected, wherein the first annular stepped surface 5 and the tooth pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com