Method for preparing platinum-copper alloy nanowire by heliothis armigera nuclear polyhedrin

A nuclear polyhedron and polyhedron protein technology, which is applied in the field of fuel cell catalyst preparation, can solve the problems of limiting the large-scale application of noble metal catalysts, high price, and inapplicability to large-scale production and application of fuel cells, achieving short preparation time, The effect of high biocompatibility and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

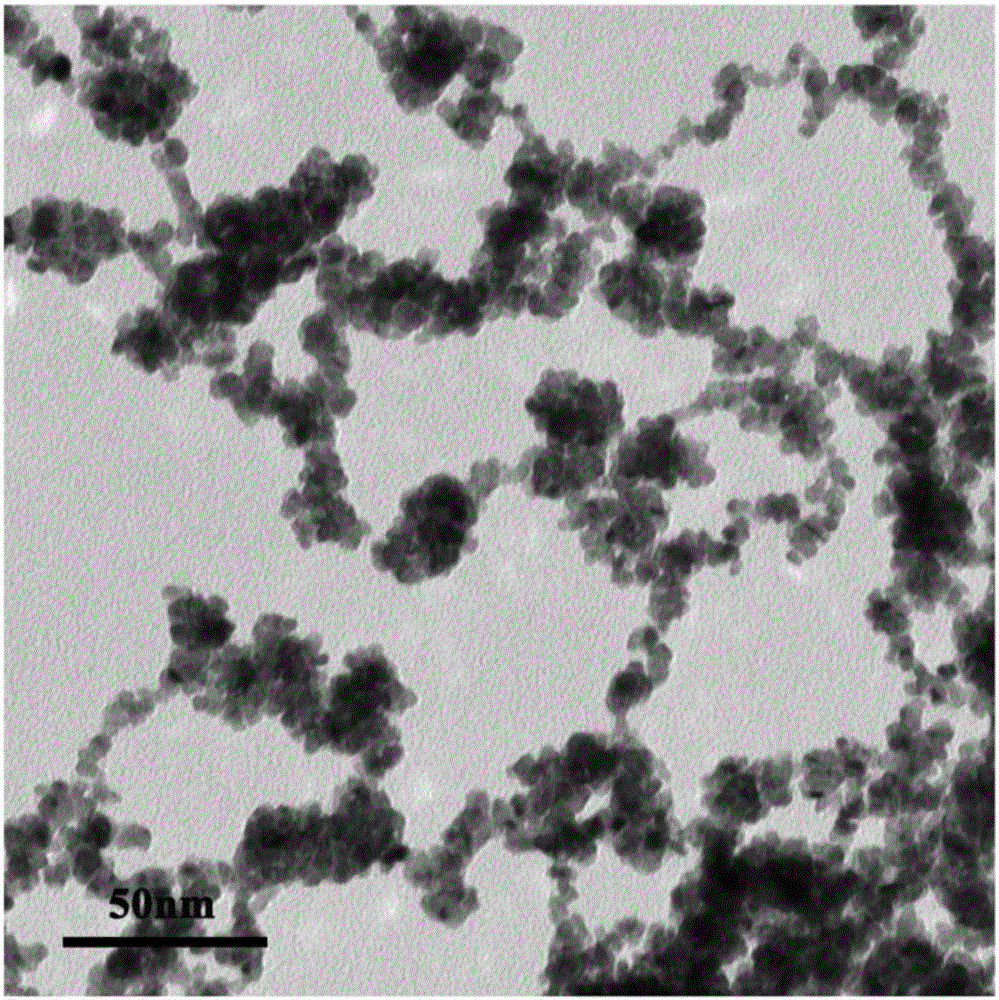

[0021] (1) Get 0.05mg of cotton bollworm polyhedron protein freeze-dried powder and disperse it with 5mL of cold ultrapure water (the ultrapure water used is the PL5124-PALL model produced by Vivendi Pure Water Systems Co., Ltd., High Wycombe, UK. prepared by an ultrapure water instrument) to obtain a polyhedrin solution with a concentration of 0.01 mg / mL. 3mL concentration of 5mMPtCl 4 solution and 1 mL of CuCl at a concentration of 5 mM 2 The solutions were mixed to obtain a mixed solution with an atomic ratio of Pt and Cu of 3:1.

[0022] (2) Take 1200 μL of the protein solution in step (1) into a 10 mL centrifuge tube, add 400 μL of the precursor mixed solution obtained in step (1), and mix well.

[0023] (3) In the mixed solution of step (2) gained, be filled with ultrapure nitrogen 5min, add the NaBH that concentration is 10mM to prepare now 4 200 μL of the solution was used for reduction, the molar ratio of sodium borohydride to the precursor mixed solution was 1:1, ...

Embodiment 2

[0026] (1) Take 0.05 mg of polyhedrin freeze-dried powder of cotton bollworm polyhedrin and disperse it with 100 mL of cold ultrapure water to obtain a polyhedrin solution with a concentration of 0.005 mg / mL. Make 1 mL of 10 mMPtCl 4 solution and 1 mL of CuCl at a concentration of 10 mM 2 The solutions were mixed to obtain a mixed solution with an atomic ratio of Pt and Cu of 1:1.

[0027] (2) Take 1000 μL of the protein solution in step (1) into a 10 mL centrifuge tube, add 200 μL of the precursor mixed solution obtained in step (1), and mix well.

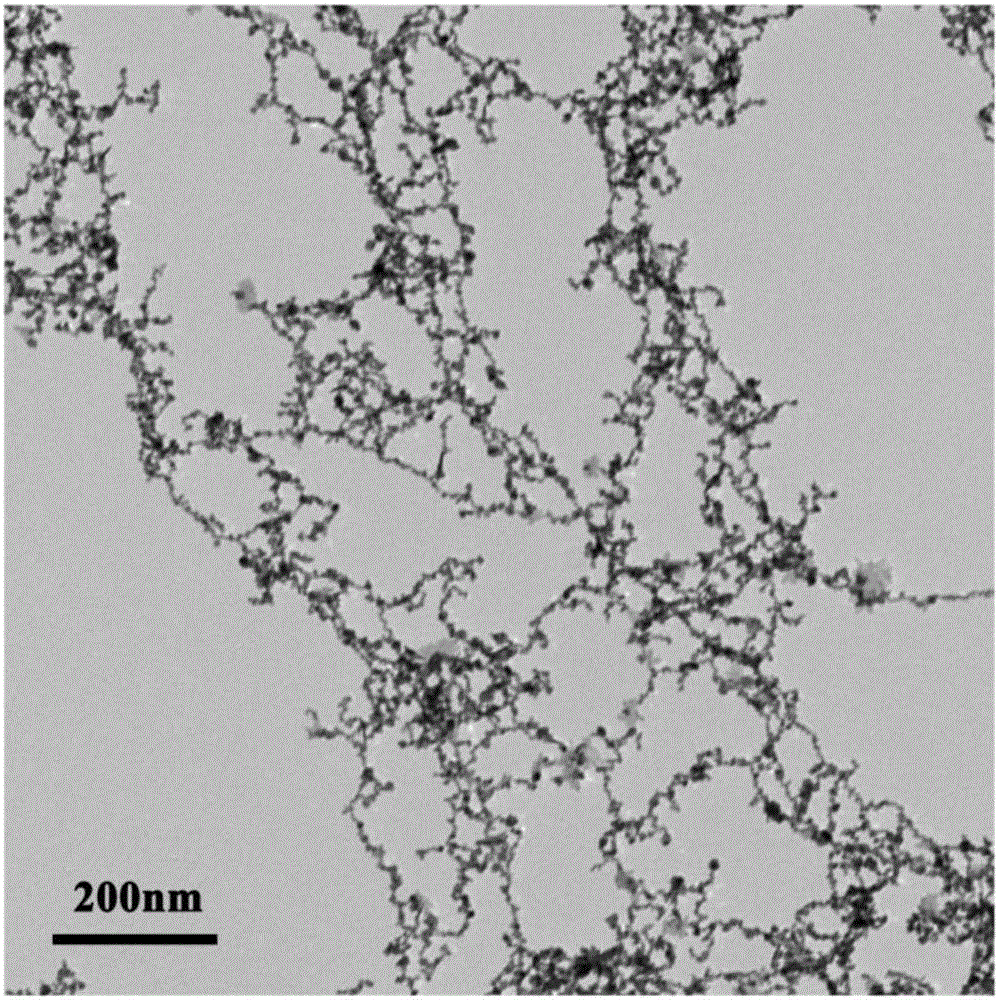

[0028] (3) In the mixed solution of step (2) gained, be filled with ultrapure nitrogen 10min, add the NaBH that concentration is 20mM to prepare now 4 300 μL of the solution was used for reduction, the molar ratio of sodium borohydride to the precursor mixed solution was 3:1, the solution changed from light yellow to black, and platinum-copper alloy nanowires with a network structure were prepared.

[0029] Such as figure 2 A...

Embodiment 3

[0033] (1) Take 0.05 mg of polyhedrin freeze-dried powder of cotton bollworm polyhedrin and disperse it with 500 mL of cold ultrapure water to obtain a polyhedrin solution with a concentration of 0.0001 mg / mL. Make 1 mL of 15 mMPtCl 4 solution and 3 mL of CuCl at a concentration of 15 mM 2 The solutions were mixed to obtain a mixed solution with an atomic ratio of Pt and Cu of 1:3.

[0034] (2) Take 1200 μL of the protein solution in step (1) into a 10 mL centrifuge tube, add 200 μL of the precursor mixed solution obtained in step (1), and mix well.

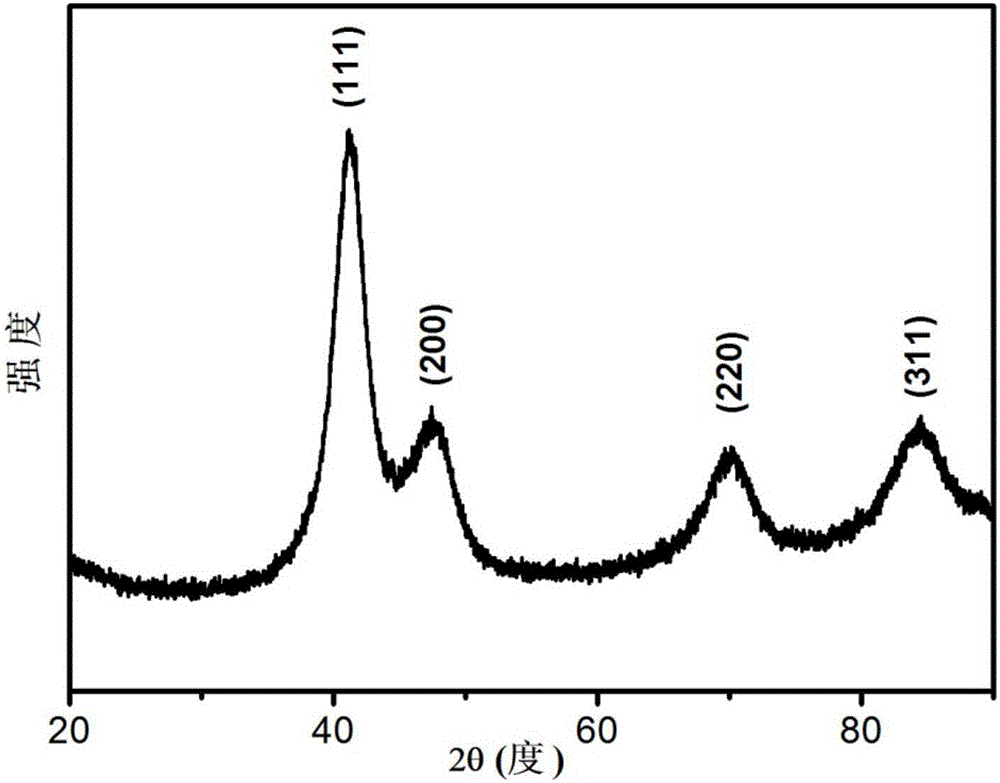

[0035] (3) In the mixed solution of step (2) gained, be filled with ultrapure nitrogen 10min, add the NaBH that concentration is 25mM to prepare now 4 600 μL of the solution was reduced, and the molar ratio of sodium borohydride to the precursor mixed solution was 5:1, and the solution changed from light yellow to black, thereby preparing platinum-copper alloy nanowires.

[0036] Such as Figure 5 As shown, the prepared plati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com