Water brake system for aerodynamic experiment kinetic energy output

An aerodynamic and braking system technology, applied in the direction of braking actuators, gear transmission mechanisms, mechanical equipment, etc., can solve the problems of high test bench site requirements, large required distance, small braking force, etc., to achieve system operation Safe and reliable, low site requirements, impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

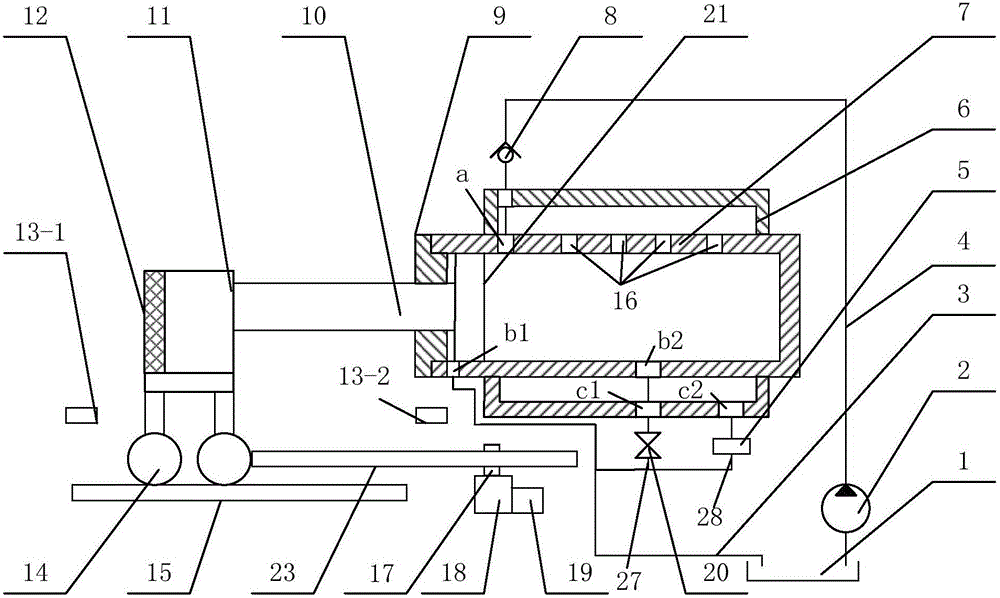

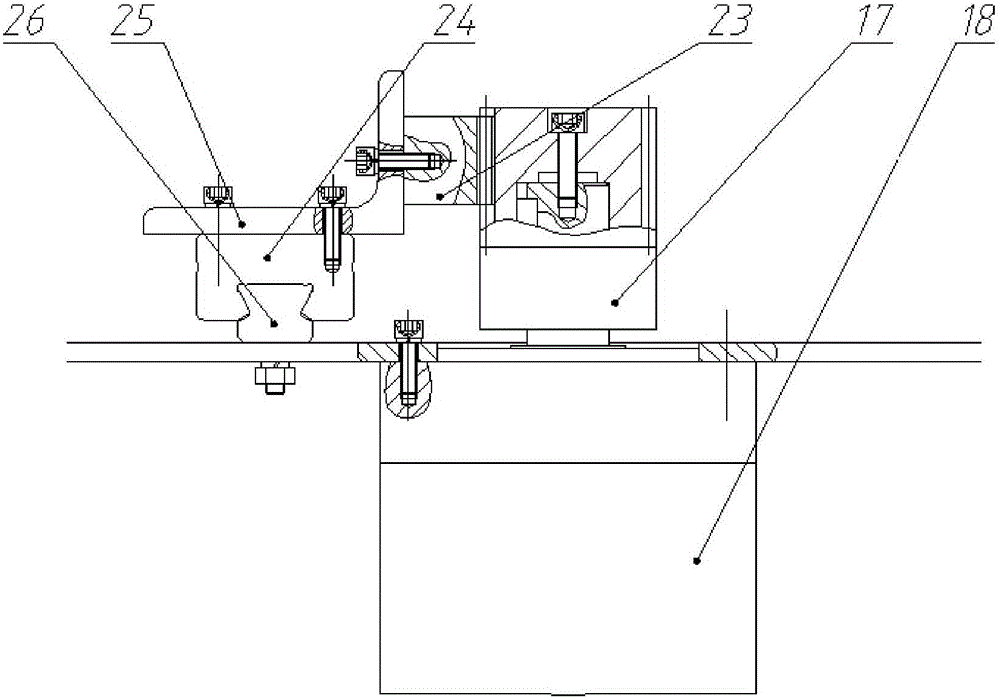

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0012] combine figure 1 , figure 2 , the present invention is mainly made up of braking mechanism, connection mechanism, return mechanism, water circulation system and control system. The piston rod of the braking mechanism is in contact with the box of the connecting mechanism, the supporting trolley of the connecting mechanism is in contact with the rack of the return mechanism, and the water circulation system and the control system assist the normal operation of the whole system. The water pump 2 draws water from the water absorption pool 1, one end of the water inlet pipe 4 is connected to the water outlet of the water pump 2, and the other end passes through the water inlet hole a of the water retaining box 6 and the water inlet a of the brake cylinder 7, and the water passes through the water inlet pipe 4 and the water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com