L-shaped light-steel frame, L-shaped light-steel assembled composite wallboard and installation method of L-shaped light-steel assembled composite wallboard

A composite wall panel and prefabricated technology, which is applied in the field of building structure engineering and prefabricated building structure, can solve the problem of low filling efficiency of thermal insulation performance of sandwich insulation layer, enhanced reliability of connection between wall and main board, thermal insulation and thermal insulation. Insufficient performance and other problems to achieve the effect of enhancing connection reliability, solving connection structure and structural problems, and improving horizontal shear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Now in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

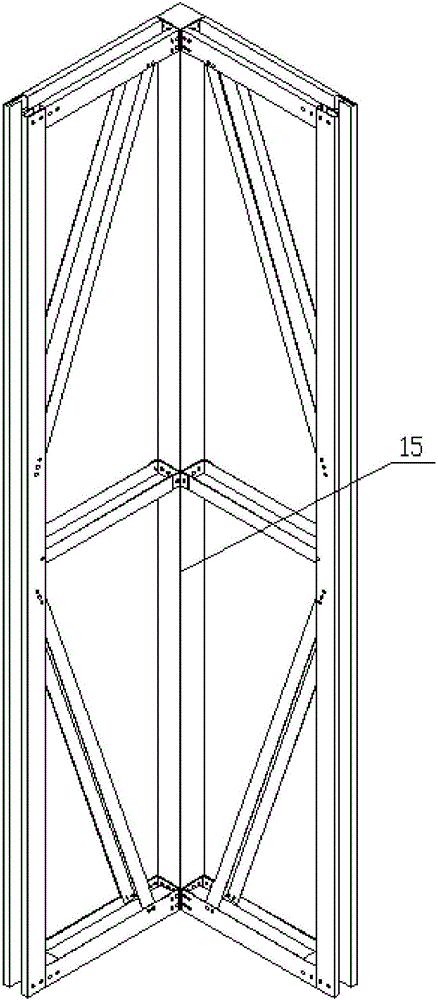

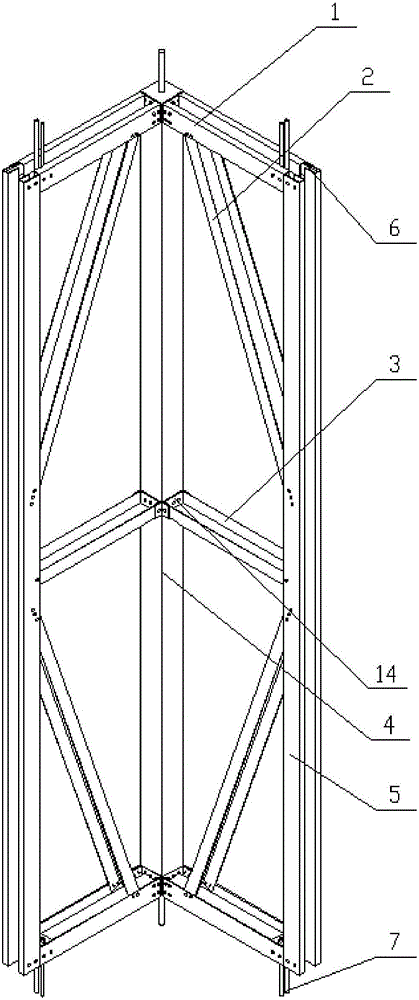

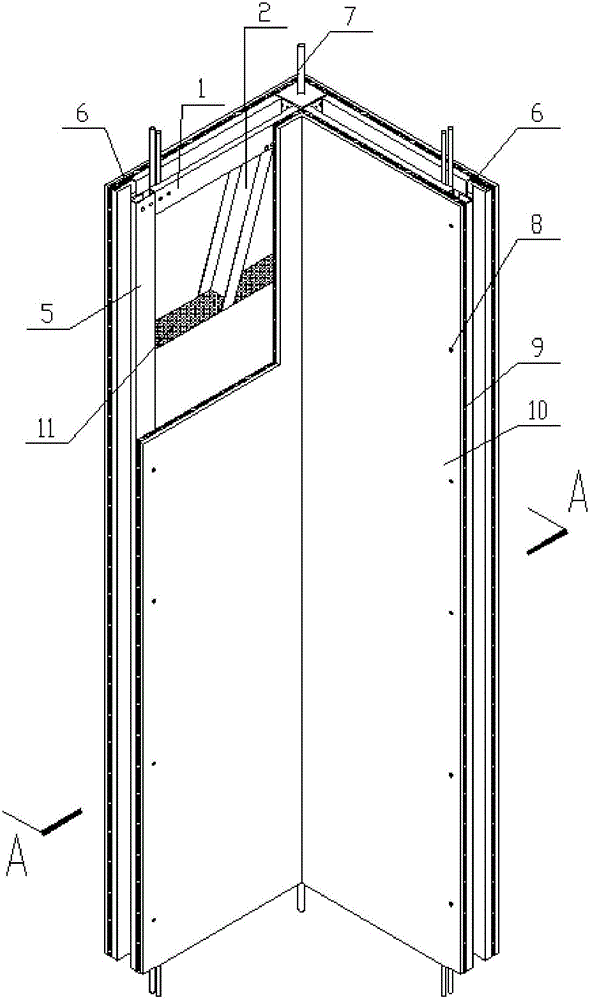

[0066] Such as Figure 1-7 As shown, the L-shaped light steel frame 15 includes a horizontal M-shaped steel 1, a horizontal C-shaped steel 3, a corner square steel 4, and a vertical M-shaped steel 5; the L-shaped light steel frame is an L-shaped structure, including a first frame and a second frame. The second frame is vertically fixed to one end of the first frame;

[0067] The first frame: the outer frame of the first frame includes horizontal M-shaped steel, vertical M-shaped steel, and corner square steel; it also includes at least one horizontal C-shaped steel as the inner frame for horizontal support; the two ends of the horizontal C-shaped steel are respectively fixed on the vertical M-shaped steel , on the corner square steel;

[0068] The second frame: the second frame shares the corner square steel with the first frame, and the externally c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com