A co-production technology for oil and gas of waste tires by catalytic cracking of waste heat of blast furnace slag

A technology for waste tires and blast furnace slag, which is applied in the field of solid waste recycling, can solve the problems of poor quality and quality of pyrolysis oil products, low energy recovery rate in the pyrolysis process, and low heating rate of tire pyrolysis, so as to improve the heat transfer efficiency. , the effect of promoting mass transfer efficiency, improving quality and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

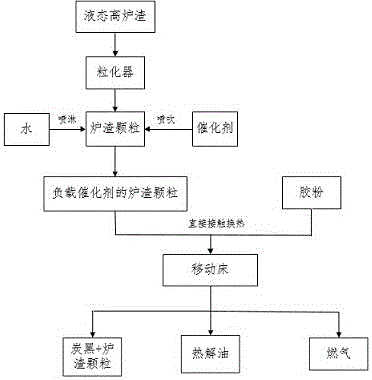

[0026] A technology for cogeneration of oil and gas from waste tires by using blast furnace slag waste heat catalytic cracking described in this embodiment is as follows:

[0027] (1) The liquid blast furnace slag discharged from the blast furnace is divided into multiple slag streams with a diameter of 10mm through the slag ditch, and enters the granulator for granulation. During the granulation process, the surface of the slag particles is sprayed according to the mass ratio of water to slag of 0.6:1 At the same time, NaOH powder is sprayed on the surface of the slag according to 50% of the mass of the slag, so that the surface of the slag particles forms porous and high-temperature particles loaded with NaOH, and the temperature of the slag particles is controlled at 600 ° C to discharge the granulator. Control within 3~5mm;

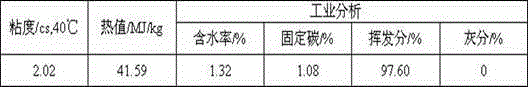

[0028] (2) The high-temperature slag particles loaded with NaOH enter the moving bed reactor and directly contact the crushed tire rubber powder as a...

Embodiment 2

[0032] A technology for cogeneration of oil and gas from waste tires by using blast furnace slag waste heat catalytic cracking described in this embodiment is as follows:

[0033] (1) The liquid blast furnace slag discharged from the blast furnace is divided into multiple slag streams with a diameter of 10mm through the slag ditch, and enters the granulator for granulation. During the granulation process, the surface of the slag particles is sprayed according to the mass ratio of water to slag of 0.8:1 At the same time, NaOH powder is sprayed on the surface of the slag according to 60% of the mass of the slag, so that the surface of the slag particles forms porous and high-temperature particles loaded with NaOH. Control within 2~3mm;

[0034] (2) The high-temperature slag particles loaded with NaOH enter the moving bed reactor and directly contact the crushed tire rubber powder as a heat carrier at a mass ratio of 0.8: 1. Part of the water vapor generated during the granulatio...

Embodiment 3

[0038] A technology for cogeneration of oil and gas from waste tires by using blast furnace slag waste heat catalytic cracking described in this embodiment is as follows:

[0039] (1) The liquid blast furnace slag discharged from the blast furnace is divided into multiple slag streams with a diameter of 10mm through the slag ditch, and enters the granulator for granulation. During the granulation process, the surface of the slag particles is sprayed according to the mass ratio of water to slag of 1.2:1 At the same time, NaOH powder is sprayed on the surface of the slag according to 80% of the mass of the slag, so that the surface of the slag particles forms porous and high-temperature particles loaded with NaOH. Control within 0~2mm;

[0040] (2) The high-temperature slag particles loaded with NaOH enter the moving bed reactor and directly contact the crushed tire rubber powder as a heat carrier at a mass ratio of 0.8:1. Part of the water vapor generated during the granulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com