Comprehensive recycling and treating method for gold concentrate roasting enterprise mine acid waste water

A technology for mine acid wastewater and gold concentrate, applied in metallurgical wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve problems such as poor effective recovery of valuable elements, reduce stockpiles and lower operating costs , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

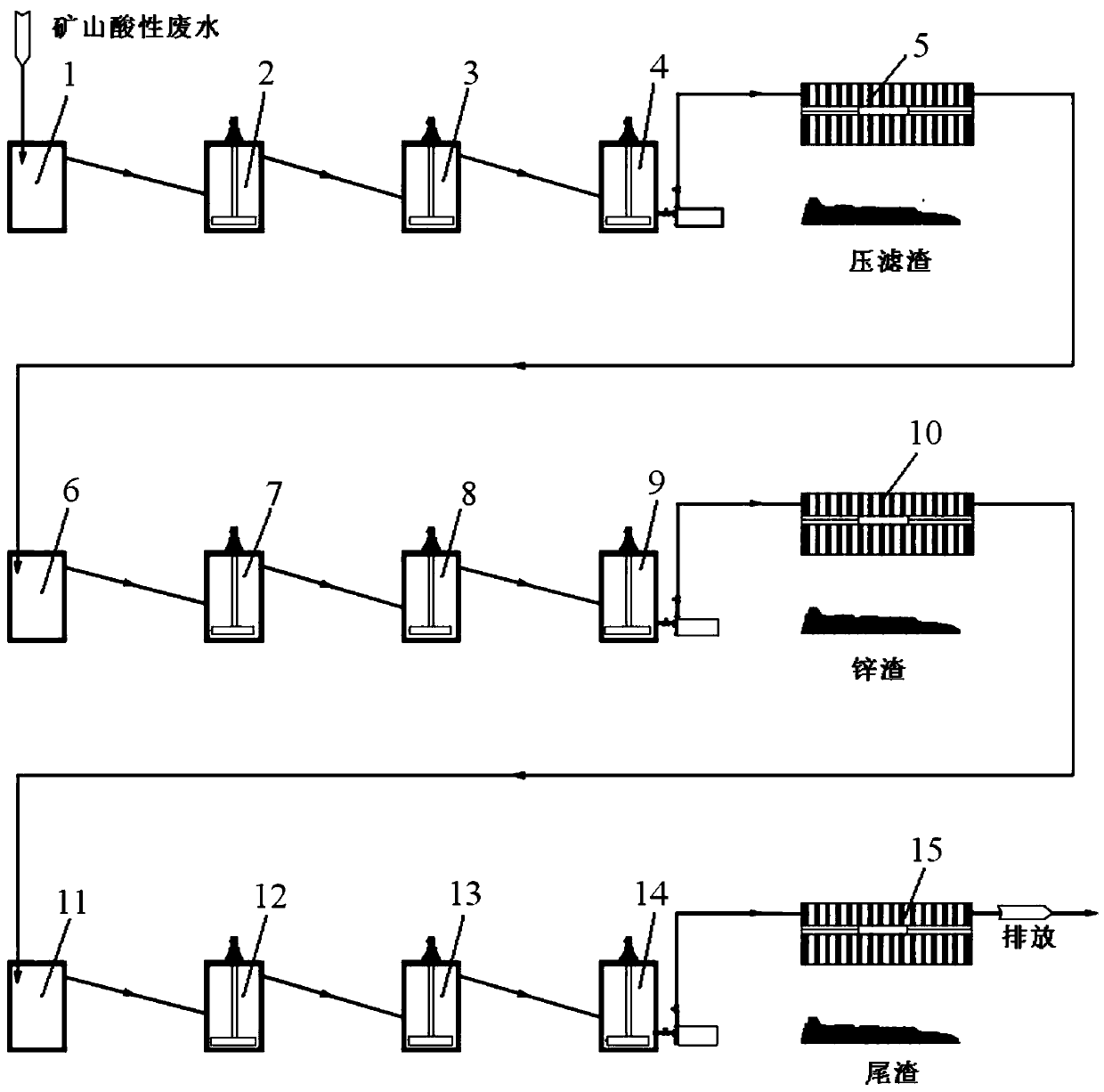

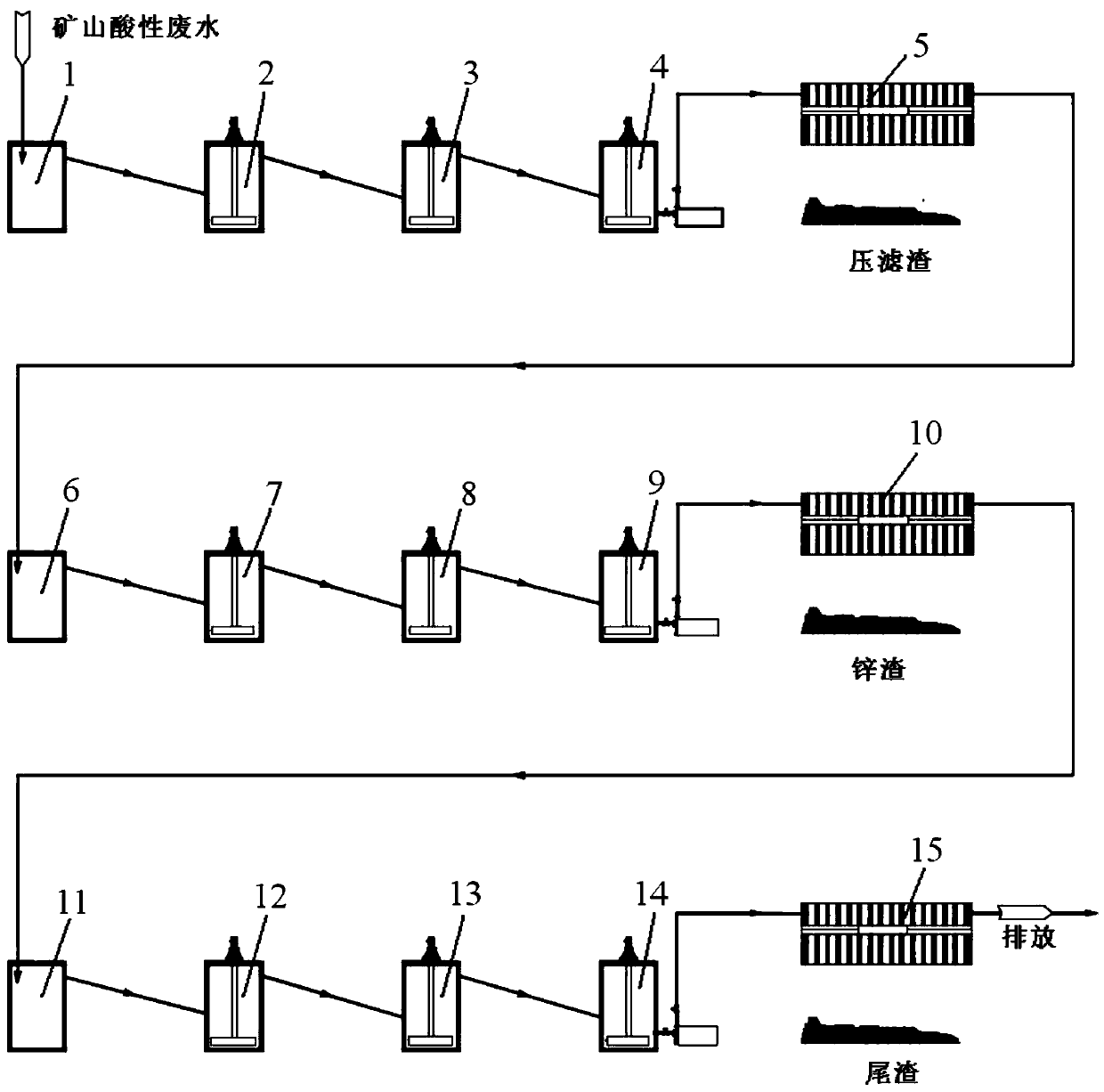

[0028] Include the following steps:

[0029] (1) pump the mine acid waste water of the gold concentrate roasting enterprise into the buffer tank-1, and the residence time is 2.5h; the pH value of the mine acid waste water is 1, and the heavy metal ions in the mine acid waste water are mainly Fe, Zn, Cu as Main, where the concentration of Fe is 3000mg / L, the concentration of Zn is 3000mg / L, and the concentration of Cu is 50mg / L;

[0030] (2) Mine acid waste water enters reactor one 2, reactor two 3, buffer tank two 4 by gravity successively from buffer tank one 1; Described reactor one, reactor two are stirring tanks, and the residence time is 1h, Buffer tank two adopts stirring tank, and the residence time is 2.5h. In reactor one and reactor two, hydrogen peroxide and lime are added. In each reactor, the hydrogen peroxide addition is 2mL / L, and the lime addition is 7g / L. The pH value in both reactor one and reactor two is 3.5;

[0031] (3) The acidic wastewater from the mine...

Embodiment 2

[0040] Include the following steps:

[0041] (1) Gold concentrate roasting enterprise mine acid waste water is pumped into buffer tank-1, and residence time is 2.5h; The pH value of described mine acid waste water is 1.3, and the heavy metal ion in the mine acid waste water is mainly Fe, Zn, Cu as Main, where the concentration of Fe is 4000mg / L, the concentration of Zn is 4000mg / L, and the concentration of Cu is 100mg / L;

[0042] (2) Mine acid waste water enters reactor one 2, reactor two 3, buffer tank two 4 by gravity successively from buffer tank one 1; Described reactor one, reactor two are stirring tanks, and the residence time is 1h, Buffer tank 2 is a stirring tank with a residence time of 2.5h. Add hydrogen peroxide and lime to reactor 1 and reactor 2. The amount of hydrogen peroxide added to each reactor is 2.5mL / L and the amount of lime added is 7.5g / L , adjust the pH value in reactor one and reactor two to be 3.7;

[0043] (3) The acidic wastewater from the mine i...

Embodiment 3

[0052] Include the following steps:

[0053] (1) Gold concentrate roasting enterprise mine acid waste water is pumped into buffer tank-1, and the residence time is 2.5h; The pH value of described mine acid waste water is 1.5, and the heavy metal ion in the mine acid waste water is mainly Fe, Zn, Cu as Main, where the concentration of Fe is 5000mg / L, the concentration of Zn is 5000mg / L, and the concentration of Cu is 150mg / L;

[0054] (2) Mine acid waste water enters reactor one 2, reactor two 3, buffer tank two 4 by gravity successively from buffer tank one 1; Described reactor one, reactor two are stirring tanks, and the residence time is 1h, Buffer tank two adopts stirring tank, and the residence time is 2.5h. In reactor one and reactor two, hydrogen peroxide and lime are added. In each reactor, the addition of hydrogen peroxide is mL / L, and the addition of lime is 8g / L. The pH value in both reactor one and reactor two is 4;

[0055] (3) The acidic wastewater from the mine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com