Highlight offset printing gloss oil

A technology of offset printing and varnish, applied in polyester coatings, coatings, etc., can solve the problems of insufficient brightness, environmental pollution, food pollution, etc., and achieve the effect of good transparency, good gloss, and not easy to yellow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

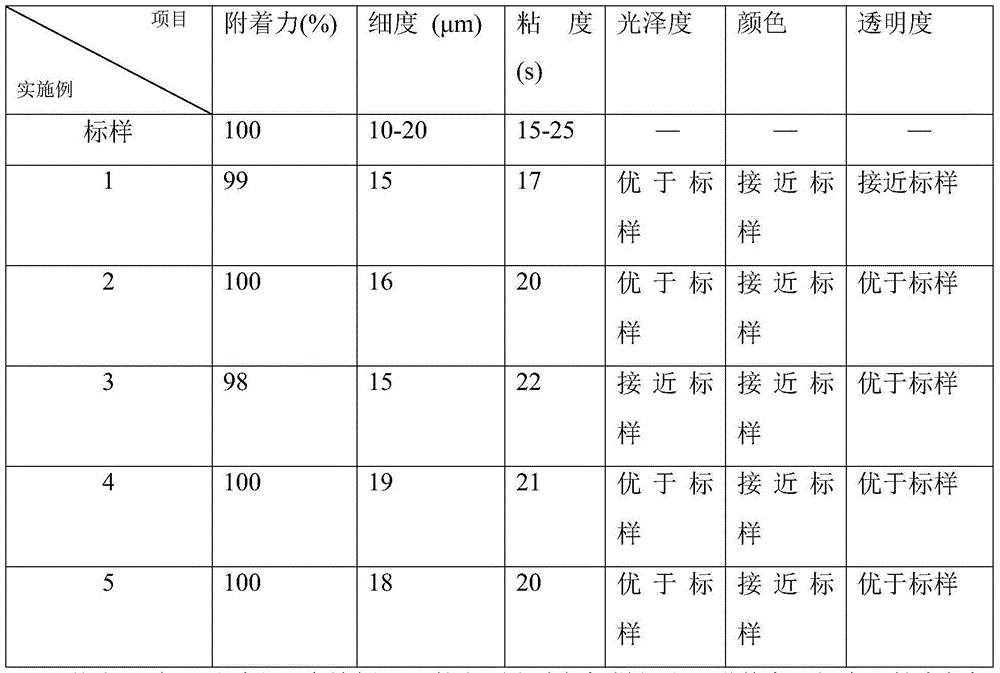

Examples

Embodiment 1

[0013] A high-gloss offset printing varnish, comprising the following raw materials by weight and composition ratio: 45 parts of phenol-free resin, 7 parts of linseed oil, 15 parts of tung oil, 10 parts of gelling agent, 0.95 parts of dispersing agent, 3 parts of brightening agent, leveling agent 0.05 parts of agent, 19 parts of high boiling point non-aromatic solvent oil.

[0014] Wherein, the synthetic steps of phenol-free resin are as follows:

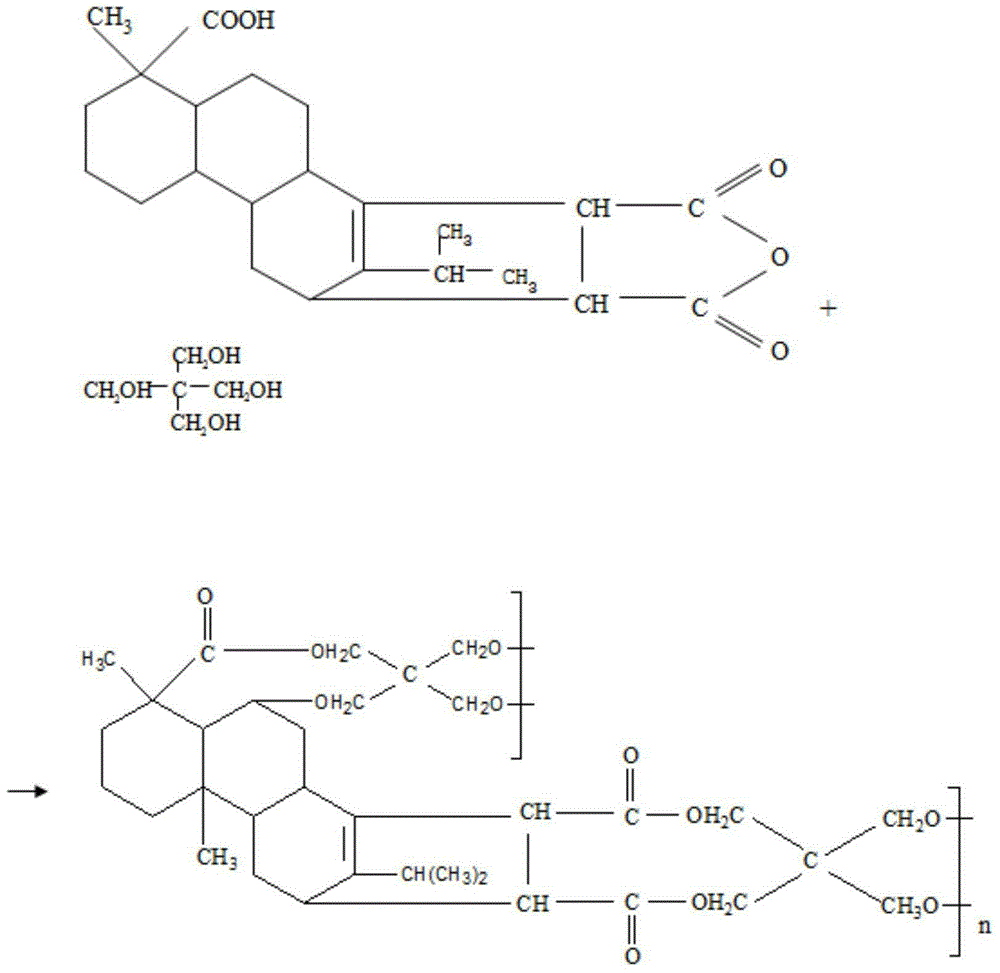

[0015] (1) Rosin and maleic anhydride carry out addition reaction:

[0016]

[0017] (2) The adduct reacts with pentaerythritol for esterification:

[0018]

Embodiment 2

[0020] A high-gloss offset printing varnish, comprising the following raw materials by weight and component ratio: 40 parts of phenol-free resin, 10 parts of linseed oil, 20 parts of tung oil, 10 parts of gelling agent, 0.93 parts of fatty amine polyoxyethylene ether, and 3 parts of brightening agent parts, 0.07 parts of polyether modified polysiloxane, and 16 parts of high boiling point non-aromatic solvent oil.

Embodiment 3

[0022] A high-gloss offset printing varnish, comprising the following raw materials by weight and composition ratio: 50 parts of phenol-free resin, 5 parts of linseed oil, 10 parts of tung oil, 10 parts of gelling agent, 0.55 parts of fatty amine polyoxyethylene ether, and 2.4 parts of brightening agent part, 0.05 part of polyether modified polysiloxane, and 22 parts of high boiling point non-aromatic solvent oil.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com