Preparation method of polyimide/silicon dioxide aerogel powder composite aerogel material

A composite aerogel and silica technology, which is applied in the field of aerogel material preparation, can solve the problems affecting industrial production and application, poor mechanical properties, easy to break, etc., and achieves low overall cost, excellent thermal insulation performance, The effect of cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

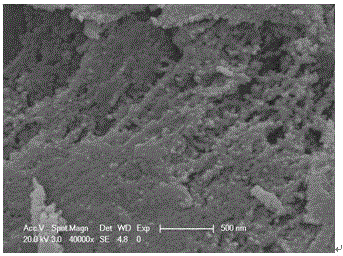

Image

Examples

Embodiment 1

[0022] Example 1: Preparation of polyimide / silica airgel powder composite airgel

[0023] Diamine (any of aromatic dianhydrides such as 4,4'-diaminodiphenyl ether, benzophenone tetracarboxylic dianhydride or pyromellitic dianhydride) and dianhydride (dianhydride is 3,3'4 , any of aromatic diamines such as 4'-biphenyltetracarboxylic dianhydride, p-phenylenediamine, 2,2-bis[4-(4-aminophenoxy)phenyl]propane) dissolved in 200mL of N - In methylpyrrolidone (take diaminodiphenyl ether: 3,3',4,4'-biphenyltetracarboxylic dianhydride = 1.672g: 2.556g as an example), synthesize polyamic acid solution, and then add 16.912g Silica airgel powder with a particle size of 20-50um, and stirred rapidly for half an hour, then added 12.1mL of dehydrating agent (oxalic acid: pyridine = 6.5mL: 5.6mL), stirred rapidly and allowed to gel at room temperature . After 24 hours, the solution was replaced three times with a mixed solution of N-methylpyrrolidone and acetone, 8-12 hours each time. Then u...

Embodiment 2

[0024] Example 2: Preparation of polyimide / silica airgel powder composite airgel

[0025] Diamine (any of aromatic dianhydrides such as 4,4'-diaminodiphenyl ether, benzophenone tetracarboxylic dianhydride or pyromellitic dianhydride) and dianhydride (dianhydride is 3,3'4 , any of aromatic diamines such as 4'-biphenyltetracarboxylic dianhydride, p-phenylenediamine, 2,2-bis[4-(4-aminophenoxy)phenyl]propane) (diaminodiphenyl Ether: 3,3',4,4'-biphenyltetracarboxylic dianhydride=1.672g: 2.556g) dissolved in 200mL of N-methylpyrrolidone (diaminodiphenyl ether: 3,3',4 ,4'-biphenyltetracarboxylic dianhydride=1.672g: 2.556g as an example),, synthesize polyamic acid solution, then add 4.228g of silica airgel powder with a particle size of 20-50um, and quickly Stir for half an hour, then add 12.1mL of dehydrating agent (oxalic acid: pyridine = 6.5mL: 5.6mL), stir rapidly and then gel at room temperature. After 24 hours, the solution was replaced three times with a mixed solution of N-m...

Embodiment 3

[0026] Embodiment 3: Preparation of polyimide / silica airgel powder composite airgel

[0027] Diamine (any of aromatic dianhydrides such as 4,4'-diaminodiphenyl ether, benzophenone tetracarboxylic dianhydride or pyromellitic dianhydride) and dianhydride (dianhydride is 3,3'4 , any of aromatic diamines such as 4'-biphenyltetracarboxylic dianhydride, p-phenylenediamine, 2,2-bis[4-(4-aminophenoxy)phenyl]propane) (diaminodiphenyl Ether: 3,3',4,4'-biphenyltetracarboxylic dianhydride=1.672g: 2.556g) dissolved in 200mL of N-methylpyrrolidone (diaminodiphenyl ether: 3,3',4 ,4'-biphenyltetracarboxylic dianhydride=1.672g: 2.556g as an example),, synthesize polyamic acid solution, then add 1.057g of silica airgel powder with a particle size of 20-50um, and quickly Stir for half an hour, then add 12.1mL of dehydrating agent (oxalic acid: pyridine = 6.5mL: 5.6mL), stir rapidly and then gel at room temperature. After 24 hours, the solution was replaced three times with a mixed solution of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com