Preparation method of polydopamine/hyaluronic acid modified coating polylactic acid membrane

A technology of hyaluronic acid and polydopamine, which is applied in the field of polymer materials and biomaterials, can solve the problems of easy peeling of the coating layer, cumbersome process, and limited depth, and achieve rapid mineralization ability, mild method, and good biocompatibility The effect of sexual biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

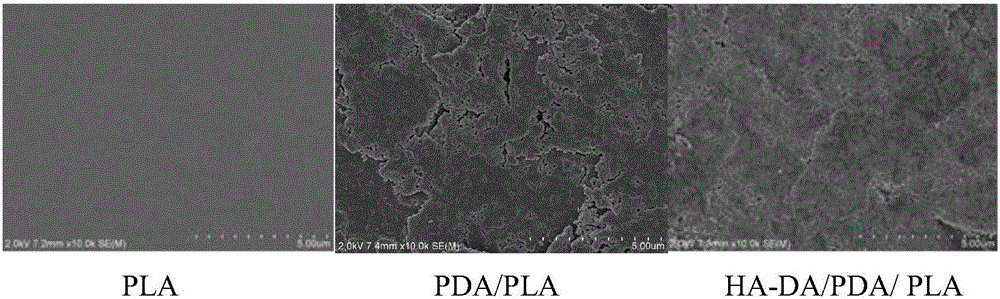

Image

Examples

Embodiment 1

[0014] Embodiment 1, the preparation of polylactic acid base material

[0015] Put the PLA polymer into a Φ8mm×1mm stainless steel mold, preheat the mold filled with raw materials in a flat vulcanizer at 175°C for 5min, and at the same temperature, press at 10MPa for 5min to prepare the PLA matrix material.

Embodiment 2

[0016] Embodiment 2, the preparation of polydopamine surface modification material

[0017] Dopamine hydrochloride was dissolved in 10 mM Tris·HCl buffer (pH=8.5) to a concentration of 2 mg / mL. Immerse the PLA matrix material ultrasonically washed with ultrapure water into the above solution, react in a water bath constant temperature oscillator at 25°C for 24 hours for surface coating; take out the PLA matrix material after the reaction, and ultrasonically wash it with ultrapure water three to four times , 40 ℃ vacuum drying for 24h.

Embodiment 3

[0018] Embodiment 3, the preparation of hyaluronic acid-dopamine (HA-DA) surface modification material

[0019] Hyaluronic acid (HA), dopamine (DA), EDC, and NHS are subjected to amidation reaction at a feed ratio (molar ratio) of 1:2:2:4 to obtain HA-DA; dissolve HA-DA in hydrochloric acid solution (pH=2.0) and make its concentration reach 2mg / ml. Finally, immerse the PDA / PLA matrix material ultrasonically washed with ultrapure water into the above solution, react in a water bath constant temperature oscillator at 25°C for 24h for surface coating; take out the matrix material after the reaction, and ultrasonically wash it with ultrapure water for three To four times, vacuum dry at 40°C for 24h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com