Silicon/silicon dioxide nanocomposite material wrapped in porous carbon spheres and its preparation method and application

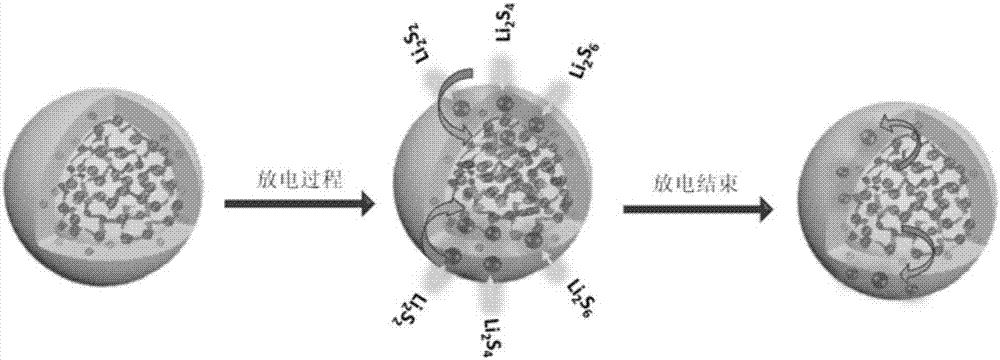

A technology of nanocomposite materials and silica, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problems of low conductivity, capacity fading, and low sulfur loading of sulfur materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

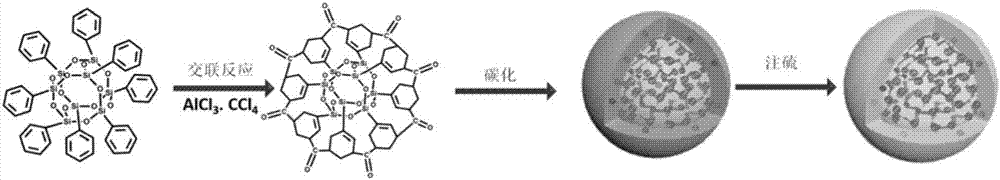

[0046] Dissolve 1.5mmol of octaphenyl-POSS in 70mL of 1,2-dichloroethane at a temperature of about 60°C, stir magnetically at 60°C for about 1h, and then add 2mmol of AlCl 3 catalyst and 40 mL of CCl 4 Cross-linking agent carries out cross-linking reaction, reacts after 10 hours, adds the mixed solution of the 95wt% ethanol solution of 100mL and water (the volume ratio of ethanol solution and water in the mixed solution is 4:1) terminates reaction, filters subsequently, obtains cross-linking agent joint reaction product.

[0047] Use a mixed solution of 95wt% ethanol solution and 5wt% dilute hydrochloric acid solution (the volume ratio of ethanol solution to dilute hydrochloric acid solution in the mixed solution is 3:1) and water to clean the cross-linked reaction product, and then dry it at 80°C 12h; subsequently, the dried cross-linked reaction product was heated to 900°C at a heating rate of 2°C / min under a nitrogen atmosphere and kept for 3h to obtain a carbonized produc...

Embodiment 2

[0055] After the carbonized product was prepared by the same method as in Example 1, the carbonized product was etched in 20wt% sodium hydroxide solution for 6 hours, then taken out, washed with water, filtered, and dried to obtain silicon / dioxide coated with porous carbon spheres. Silicon nanocomposites.

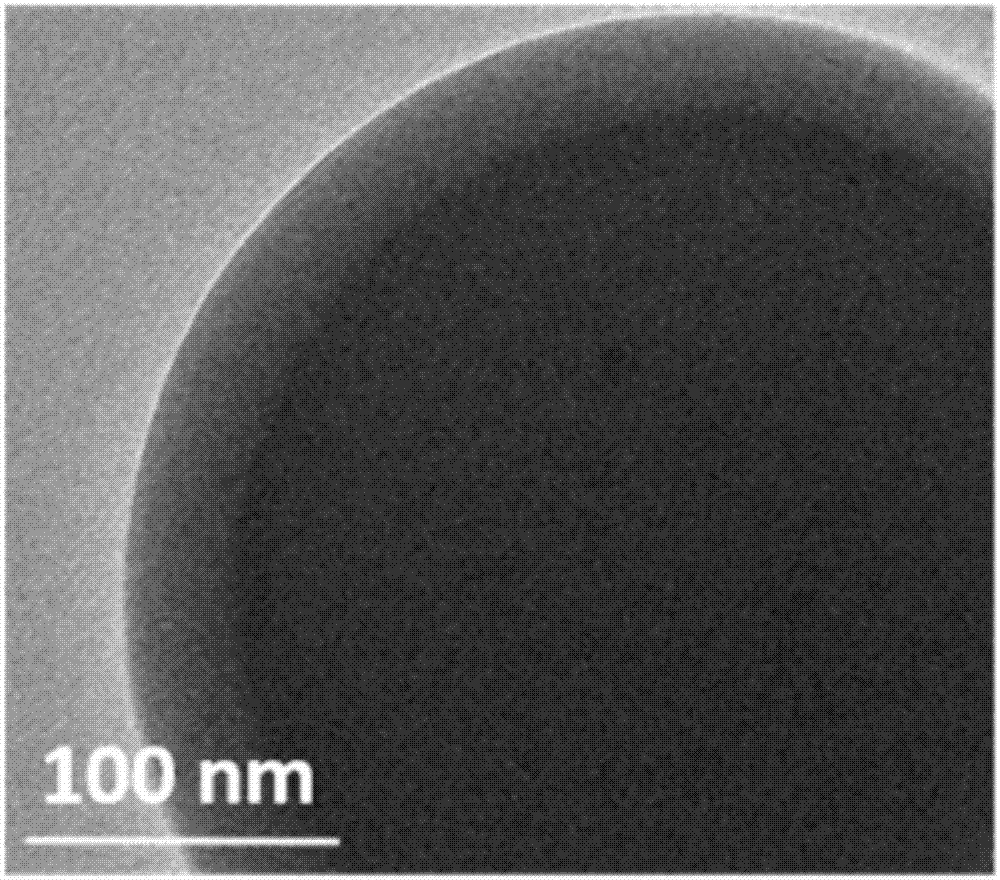

[0056] The method of Example 1 was used to analyze the nanocomposite prepared above. The results show that the nanocomposite material is a spherical material with a particle size of about 420nm, which has a large number of micropores and mesopores, and there is a pure phase of silicon / silicon dioxide. The specific surface area and total pore volume are shown in Table 1. In addition, the Si / SiO in the nanocomposite 2 The content is 24.7wt%.

Embodiment 3

[0058] After the carbonized product was prepared by the same method as in Example 1, the carbonized product was etched in 20wt% sodium hydroxide solution for 24 hours, then taken out, washed with water, filtered, and dried to obtain silicon / dioxide coated with porous carbon spheres. Silicon nanocomposites.

[0059] The method of Example 1 was used to analyze the nanocomposite prepared above. The results show that the nanocomposite material is a spherical material with a particle size of about 420nm, which has a large number of micropores and mesopores, and there is a pure phase of silicon / silicon dioxide. The specific surface area and total pore volume are shown in Table 1. In addition, the Si / SiO in the nanocomposite 2 The content is 4.6wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com