Preparation method for thermoelectric composite material of polyaniline in-situ polymerization clad PEDOT modified nano-carbon

A nano-carbon material and in-situ polymerization technology, which is applied in the manufacture/processing of thermoelectric devices, and lead-out wire materials of thermoelectric devices, can solve the problems of low thermoelectric performance, and achieve short preparation time, simple and stable process, and good promotion. combined effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

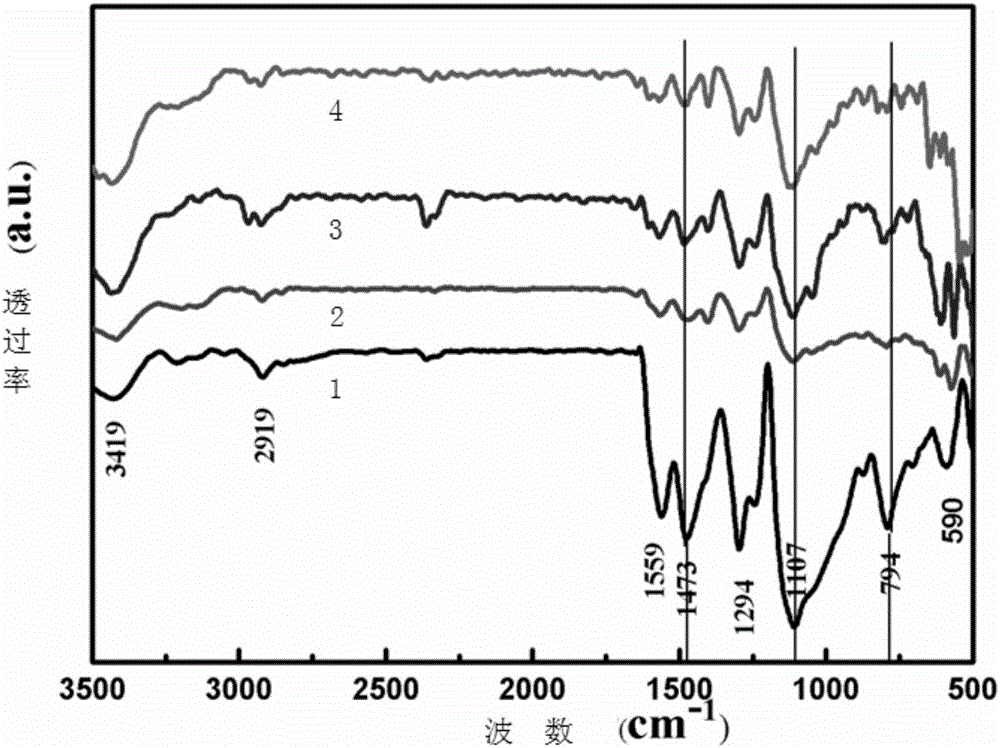

Image

Examples

specific Embodiment approach 1

[0021] Embodiment 1: In this embodiment, the preparation method of polyaniline in-situ polymerization coated PEDOT modified nano-carbon thermoelectric composite material is realized according to the following steps:

[0022] 1. Add organic solvent to PEDOT:PSS solution, add nano-carbon material after stirring evenly, ultrasonically stir until uniformly dispersed, then add inorganic acid or organic acid, and obtain PEDOT-modified nano-carbon material suspension after stirring;

[0023] 2. Using a pipette, add aniline to the PEDOT-modified nano-carbon material suspension, and ultrasonically stir the reaction at a temperature of 0-30° C. to obtain a PEDOT-modified nano-carbon material suspension containing aniline;

[0024] Three, the oxidizing agent that is 1:1 with the molar ratio of aniline is dissolved in the protonic acid, obtains the protonic acid solution containing oxidant, then the protonic acid solution containing oxidant is dropped into the PEDOT modified nano-carbon ma...

specific Embodiment approach 2

[0027]Specific embodiment two: the difference between this embodiment and specific embodiment one is that the organic solvent described in step one is dimethyl sulfoxide (DMSO), ethylene glycol (EG), tetrahydrofuran (THF), One or more mixed solvents in N-N dimethylformamide (DMF), polyethylene glycol (PEG). Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0028] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, an organic solvent is added to the PEDOT:PSS solution, and after stirring evenly, nano-carbon materials are added in a ratio of 0.1-10 mg / mL. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com