A kind of preparation method of solar cell sheet

A technology of solar cells and silicon wafers, which is applied in the field of solar cells, can solve the problems of complex production process, slow production speed, manual operation, etc., and achieve the effects of strong versatility, strong practicability, and accurate temperature measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

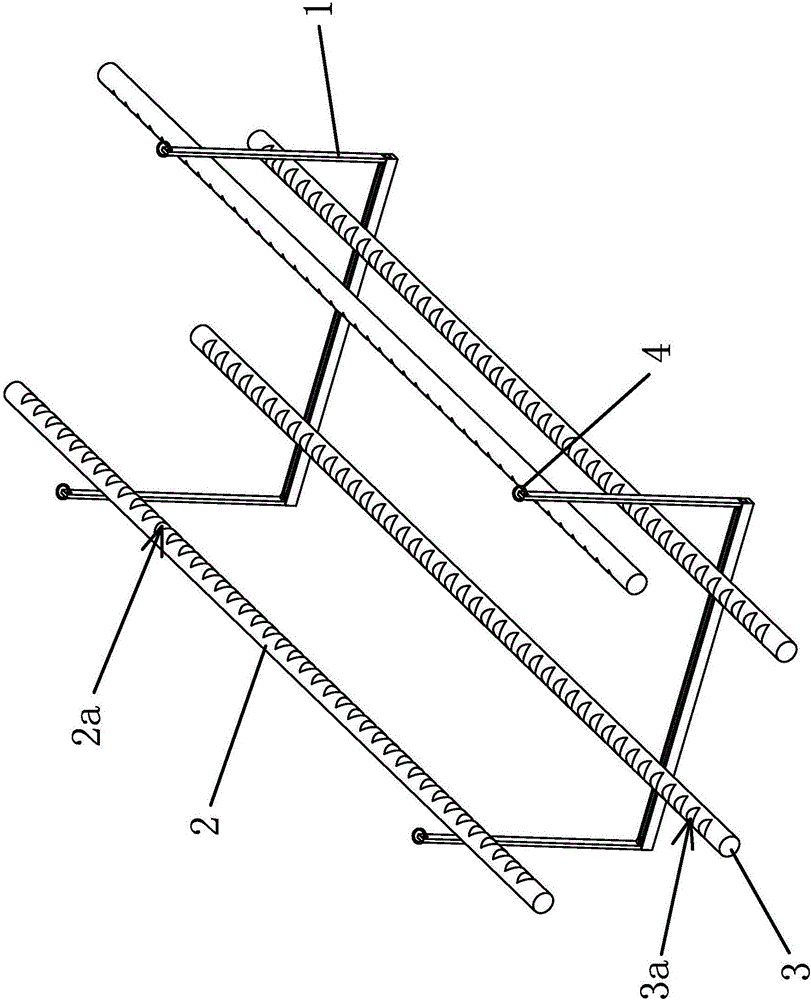

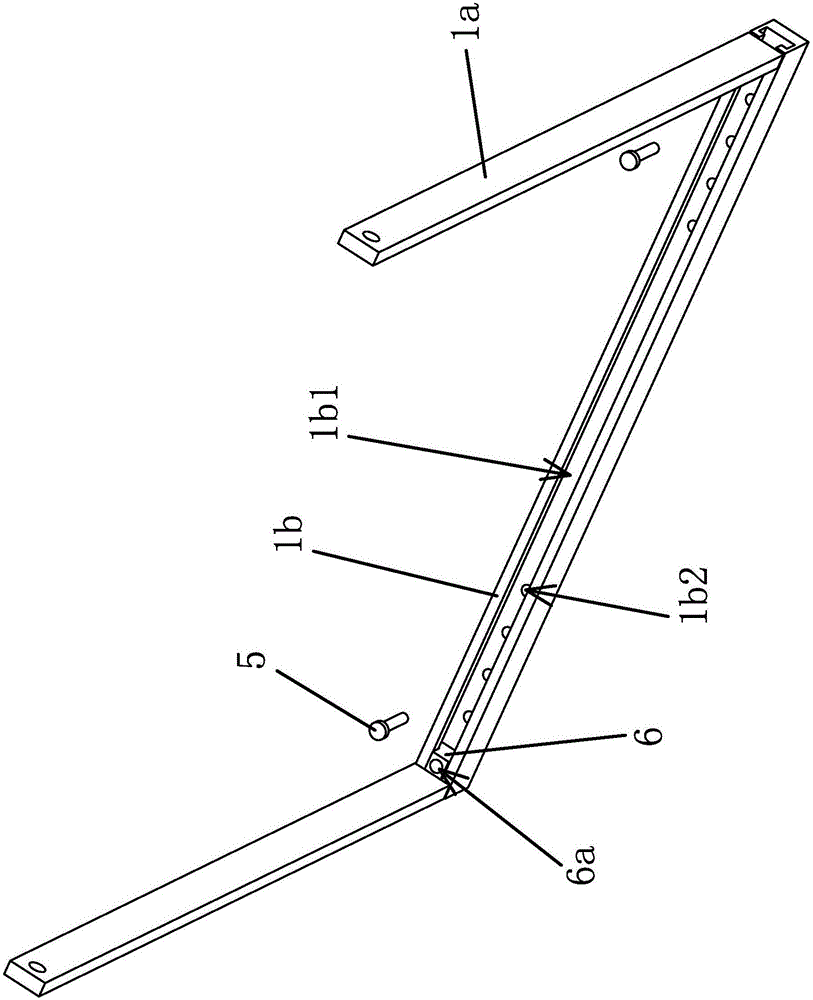

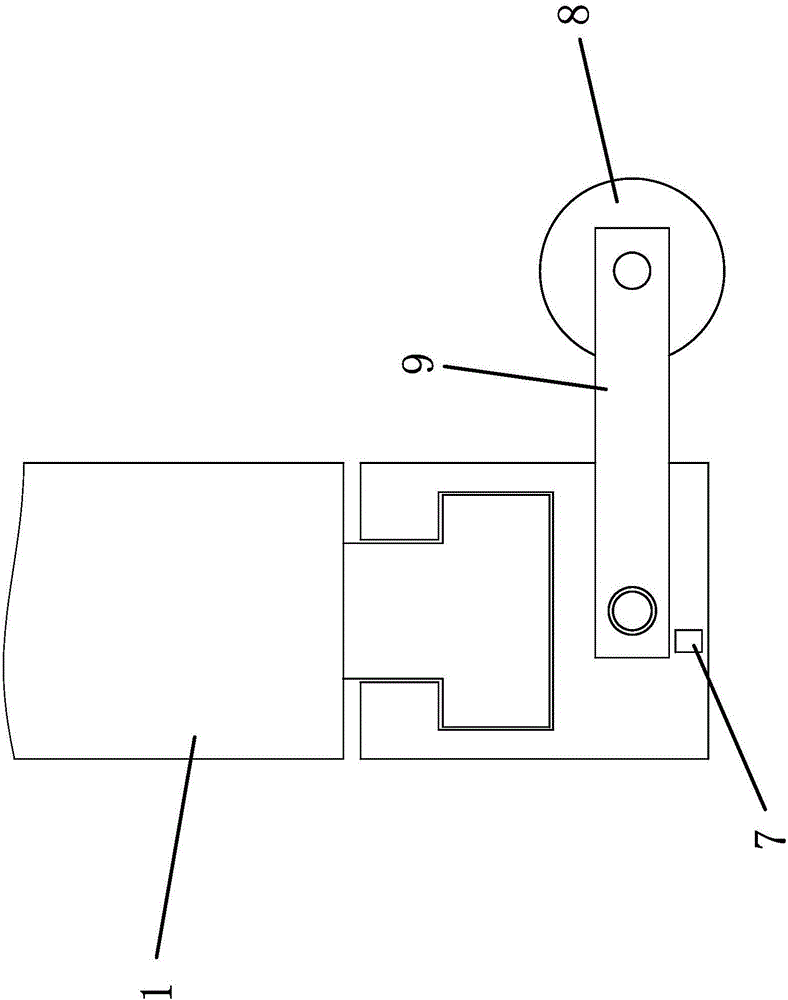

[0076] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0077]The preparation method of the solar battery sheet comprises the following steps:

[0078] a. Inspect the purchased silicon wafers and remove unqualified silicon wafers; b. Put the inspected silicon wafers into an alkaline solution for texturing, and the alkaline solution is sodium hydroxide; c. Silicon wafer is put into quartz boat, and quartz boat is put into common diffusion equipment to carry out diffusion, and in the present embodiment, diffusion equipment adopts the existing product that can buy on the market; d, the silicon wafer that diffuses is put into Carry out etching in common etching machine, provide ozone for etching machine by ozone generator, in the present embodiment, etching machine adopts the exist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com