Device and method for analyzing content of phosphorane impurities in electronic grade arsenic hydride

A technology for the content of phosphine and impurities in arsane, which is applied in the direction of measuring devices, analysis materials, material separation, etc., can solve the problems of inability to detect trace phosphine impurity content of arsane, impurity separation, etc., and achieve high accuracy and low consumption The effect of small sample size and short analysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

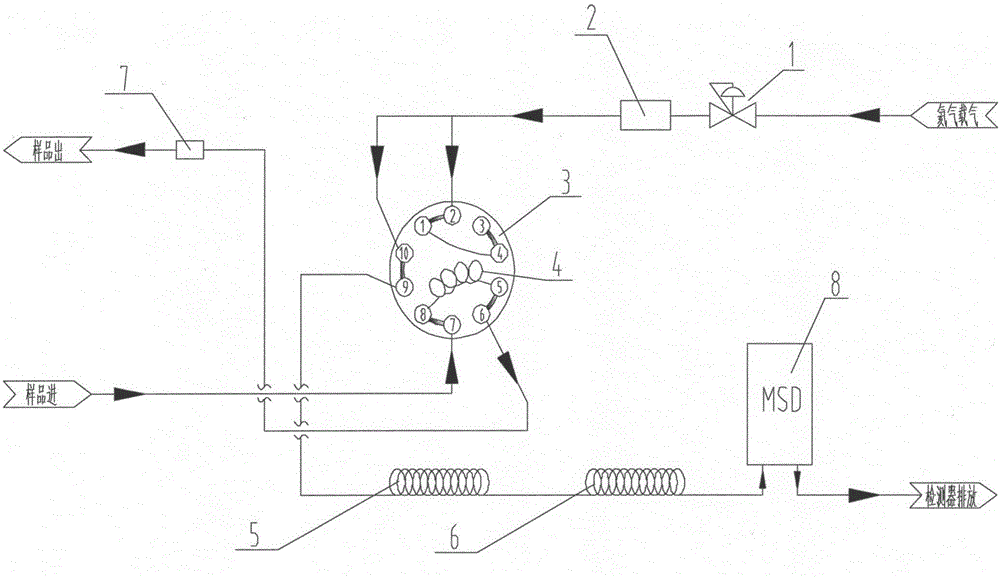

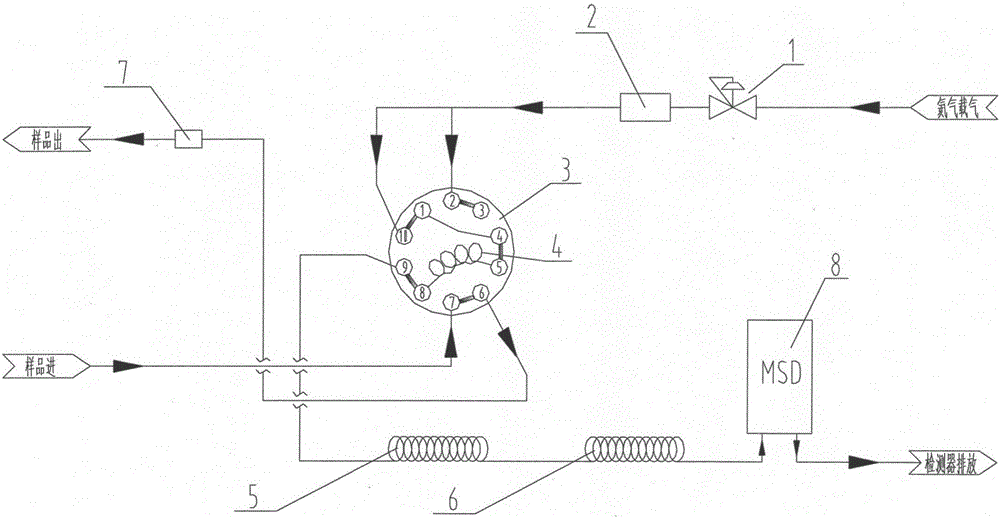

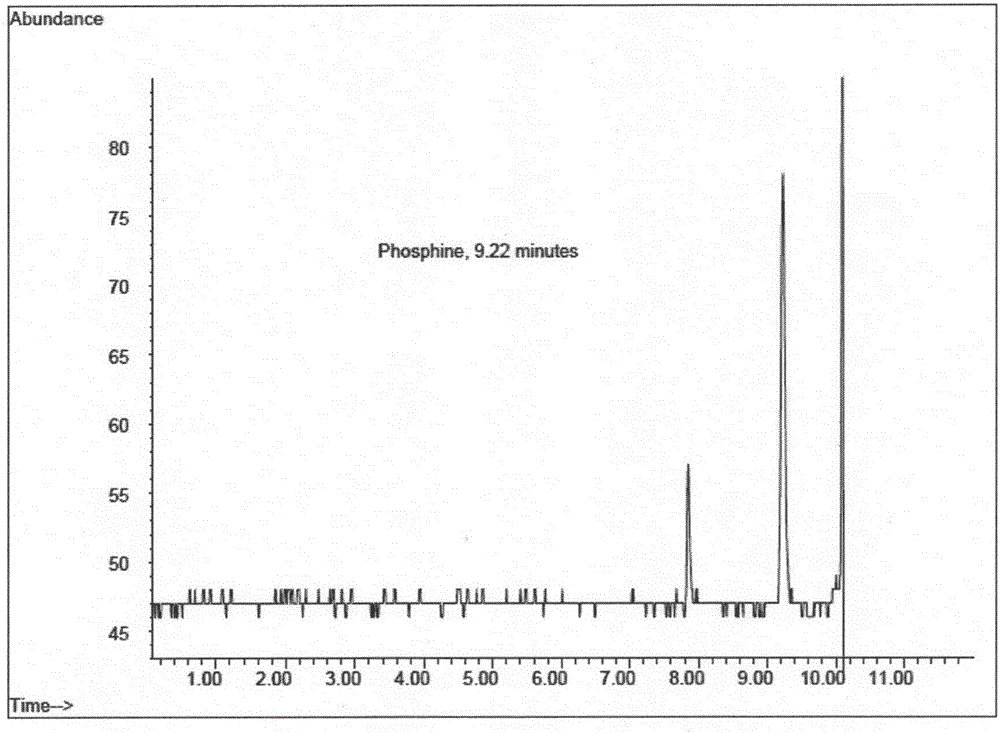

[0027] The analysis device for impurity content of phosphine in electronic grade arsine in this embodiment includes a pressure regulating valve 1, a helium gas purifier 2, a ten-way valve 3, a quantitative loop 4, a first separation and analysis column 5, and a second separation and analysis column 6. Flow meter 7 and mass selective detector 8. The ten-port valve 3 has ports 1 to 10, and the port 10 of the ten-port valve 3 is connected to the carrier gas inlet, and a helium purifier is installed on the pipeline between the port 10 of the ten-port valve 3 and the carrier gas inlet 2 and pressure regulating valve 1. Port No. 9 of the ten-way valve 3 is connected to the first separation analysis column 5, the first separation analysis column 5 is connected to the second separation analysis column 6, the second separation analysis column 6 is connected to the mass selective detector 8, and the outlet of the mass selective detector 8 Connect the detector exhaust line. Port No. 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com