Emergency support equipment and method for tunnel excavation vault

A technology for tunnel excavation and vaulting, which is used in tunnels, tunnel linings, mining equipment, etc., can solve the problems of reducing rebound rate, bounce off, insufficient bonding time, etc., to ensure personal safety, construction safety, increase The effect of engineering quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

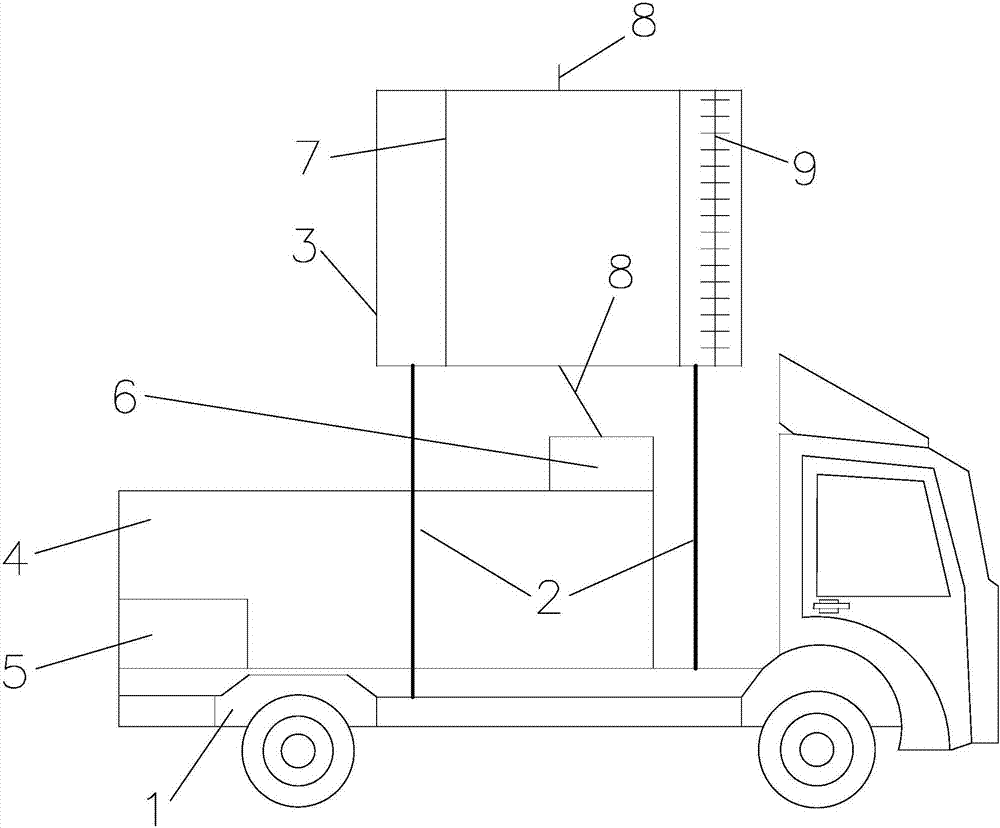

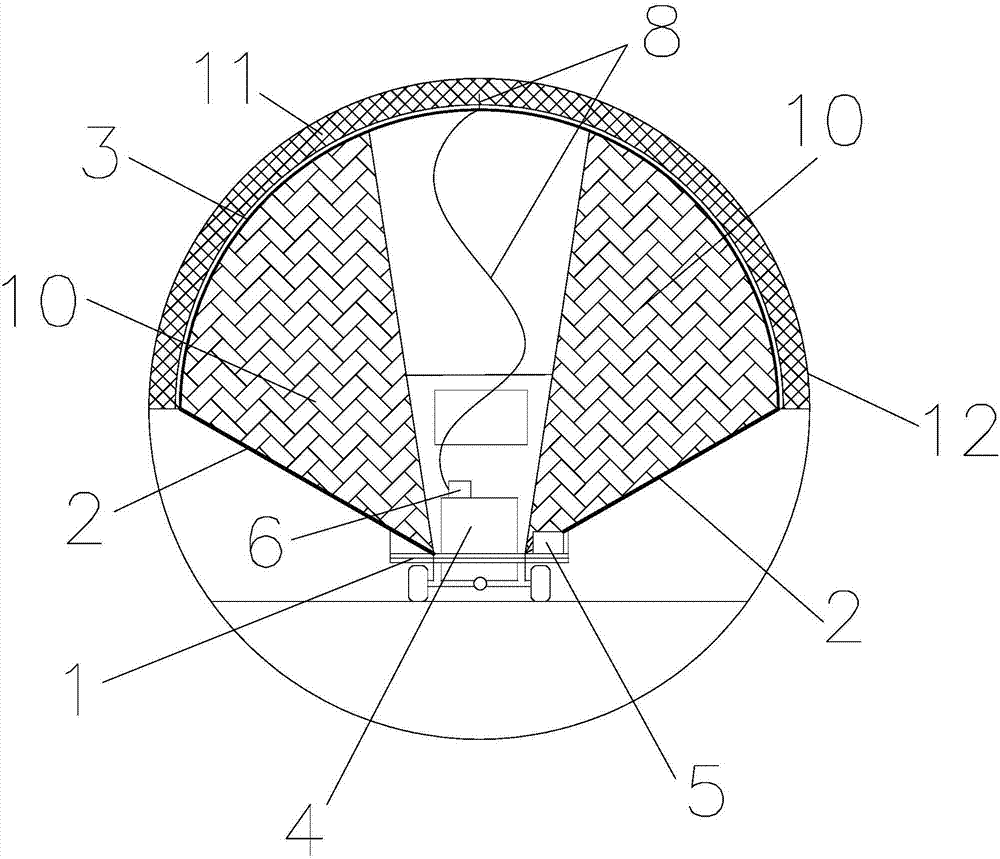

[0028] like Figure 1 ~ Figure 2 As shown, a kind of tunnel excavation vault emergency support equipment includes a carrier vehicle 1 and an arc-shaped arch plate 3. The carrier vehicle 1 of the present invention is a double-axle truck with a power greater than 100 horsepower. The carrier vehicle 1 is loaded with concrete The slurry tank 4 and the controller 5, the arc-shaped arch plate 3 is connected to the top of the carrier vehicle 1 through a support frame, the concrete slurry tank 4 is provided with a grouting pump 6 communicating with the inner cavity of the concrete slurry tank 4, and the controller 5 has a grouting pump switch module inside, and the grouting pump 6 is electrically connected to the grouting pump switch module of the controller 5; the quick-setting concrete dry material and water are delivered to the arc-shaped arch plate 3 by the grouting pump 6 through the grouting pipe 8 In the upper part, the controller 5 controls the opening and closing of the grout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com