Copper alloy and aluminum alloy composite wire and preparation processing method thereof

A technology of composite wire and processing method, which is applied in the field of plastic processing and heat treatment of non-ferrous metal materials, to achieve the effects of enhanced bonding strength, good electrical conductivity, and improved electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

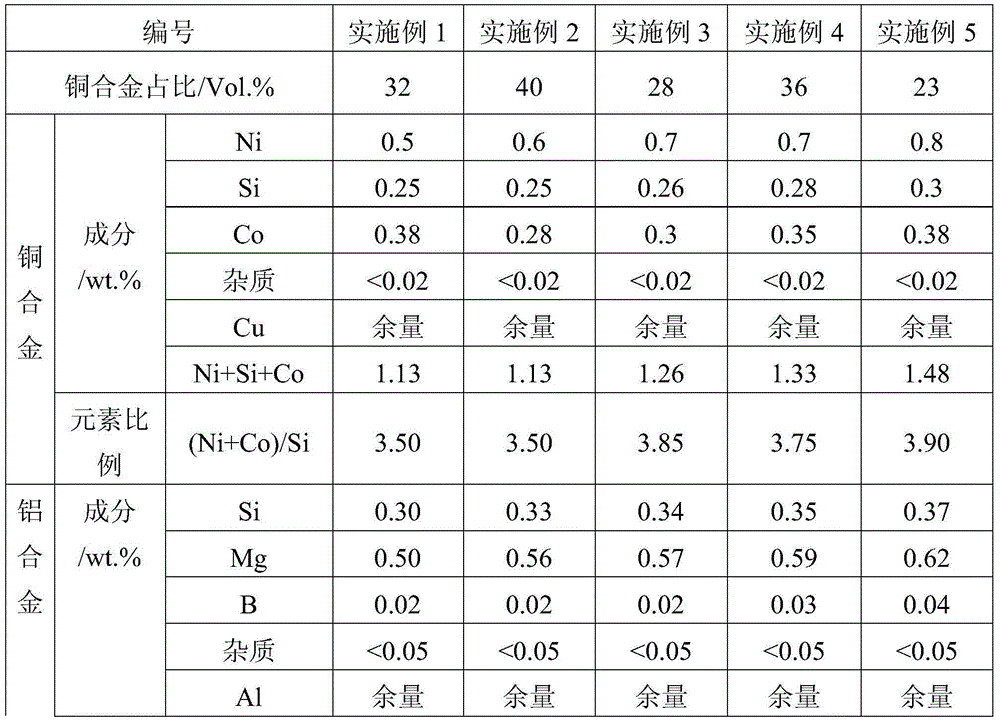

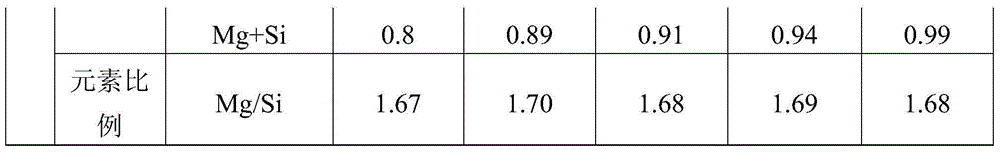

[0047] The structure and composition of the composite wire used are shown in Example 1 in Table 1.

[0048] The specific process route is:

[0049] A copper alloy ingot with a diameter of 95mm is hot-extruded into a tube blank with an outer diameter of 50mm and a wall thickness of 10mm. Secondary cold rolling in each pass to an outer diameter of 23 mm and a wall thickness of 4 mm, straightening, face milling, and pickling.

[0050] Aluminum alloy ingots with a diameter of 70mm are hot-extruded into rods with a diameter of 18mm, straightened and cleaned.

[0051] The copper alloy tube and the aluminum alloy rod are combined and cold-rolled to a diameter of 8mm in 11 passes, the composite rod is drawn to a diameter of 1.2mm in 24 passes after one heat treatment, and finally the composite wire is made into a finished composite wire after a second heat treatment .

[0052] The specific process parameters are as follows:

Embodiment 2

[0064] The structure and composition of the composite wire used are shown in Example 2 in Table 1.

[0065] The specific process route is:

[0066] The copper alloy ingot with a diameter of 95mm is hot-extruded into a tube blank with an outer diameter of 40mm and a wall thickness of 10mm. The second pass is cold rolling to an outer diameter of 18mm and a wall thickness of 4mm, straightening, face milling, and pickling.

[0067] Aluminum alloy ingots with a diameter of 70 mm are hot-extruded into rods with a diameter of 13 mm, straightened and cleaned.

[0068] The copper alloy tube and the aluminum alloy rod are combined and cold-drawn to a diameter of 6mm in 11 passes, the composite rod is drawn to a diameter of 1mm in 28 passes after one heat treatment, and finally the composite wire is made into a finished composite wire after a second heat treatment .

[0069] The specific process parameters are as follows:

[0070] (1) Copper alloy pipe extrusion process: extrusion te...

Embodiment 3

[0081] The structure and composition of the composite wire used are shown in Example 3 in Table 1.

[0082] The specific process route is:

[0083] A copper alloy ingot with a diameter of 95mm is hot-extruded into a tube blank with an outer diameter of 30mm and a wall thickness of 5mm. Second cold rolling to 13mm outer diameter, 2mm wall thickness, straightening, face milling, pickling.

[0084] Aluminum alloy ingots with a diameter of 70 mm are hot-extruded into rods with a diameter of 10 mm, straightened and cleaned.

[0085] The copper alloy tube and the aluminum alloy rod are combined and cold-drawn to a diameter of 5mm in 12 passes, and the composite wire is drawn to a diameter of 0.404mm in 48 passes after one heat treatment, and finally the composite wire is made into a finished product after a second heat treatment .

[0086] The specific process parameters are as follows:

[0087] (1) Copper alloy tube extrusion process: extrusion temperature 890°C, extrusion rati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com