Manufacture and transportation technology for double-joint integrally-welded trusses

A dual-node, control technology, applied in manufacturing tools, welding equipment, construction, etc., can solve the problems of sporadic operations in high-altitude operations, which is not conducive to ensuring the safety of bridges, so as to reduce the difficulty of construction site operations, shorten the erection period of construction sites, reduce human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

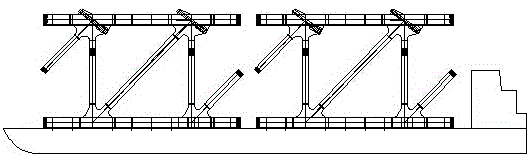

[0021] A double-node overall welded girder manufacturing and transfer technology, including dimensional accuracy control technology for 30m-long rods and integral welded girders, girders with straight instead of curved matching assembly technology, large overweight girder turning and transfer technology, girder Chip three-dimensional shipping technology;

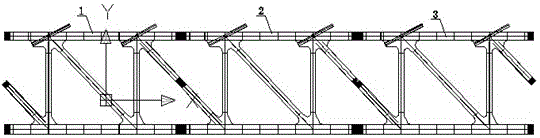

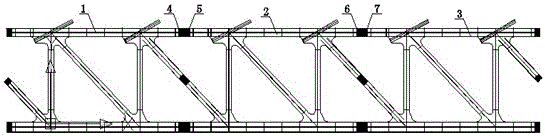

[0022] 1) The dimensional accuracy control technology of 30m long rods and integrally welded girders, the dimensional accuracy control technology of 30m long rods and integrally welded girders adopts software entity modeling, simulates welding, and understands the welding deformation trend of steel girders. Deformation, reserve welding shrinkage allowance, optimize welding parameters, standardize the welding sequence to control the dimensional accuracy of 30m long rods, and ensure the forming size of girders through "2+1" matching assembly technology, that is, the first girder is the mother girder 1. Based on mother beam 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com